The spray drying process is one of the most efficient and widely used methods for transforming a liquid or slurry into a dry powder. It plays a crucial role in various industries such as food, pharmaceuticals, and chemicals. Whether producing milk powder, instant coffee, or fine ceramic materials, spray drying ensures that products retain their quality, stability, and functionality.

What Is the Spray Drying Process?

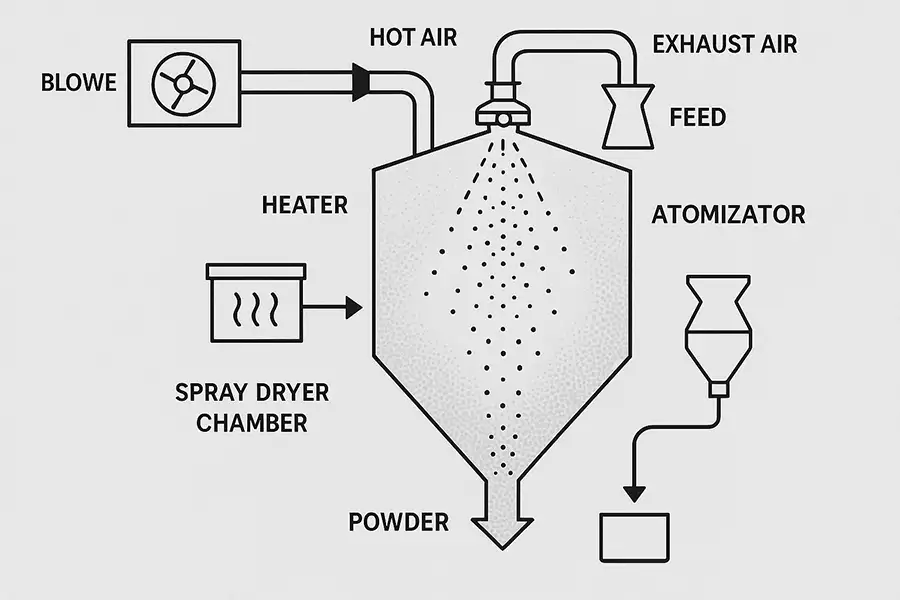

Spray drying is a method that converts a liquid feed into a dry powder by rapidly drying it with a hot gas. The process involves atomizing the liquid into fine droplets and introducing them into a chamber where hot air evaporates the moisture almost instantly. The dried particles are then separated and collected as powder.

According to a study by the University of Cambridge, spray drying can reduce drying time by up to 90% compared to traditional drying methods. This makes it highly efficient for large-scale industrial production.

“Spray drying is not just about drying; it’s about preserving the essence of a product in powder form.”

How Does the Spray Drying Process Work?

The process can be broken down into four main stages:

-

Atomization: The liquid feed is converted into tiny droplets using a nozzle or rotary atomizer.

-

Drying: The droplets are exposed to hot air, causing rapid evaporation of the solvent.

-

Separation: The dried particles are separated from the air in a cyclone separator or bag filter.

-

Collection: The final powder is collected and packaged for further use.

Each of these steps is carefully controlled to ensure consistent product quality. For instance, the temperature and air flow rate are optimized to prevent overheating or degradation of sensitive materials.

Question:

What determines the final particle size in the spray drying process?

Answer: The particle size largely depends on the atomizer type, feed viscosity, and drying temperature. Smaller droplets result in finer powders, while higher feed viscosity or lower air temperature can lead to larger particles.

Applications of Spray Drying

Spray drying is used across multiple industries:

-

Food Industry: For producing milk powder, instant coffee, egg powder, and flavors.

-

Pharmaceuticals: For encapsulating active ingredients and creating uniform drug particles.

-

Chemicals: For manufacturing catalysts, detergents, and polymers.

-

Biotechnology: For drying enzymes and probiotics while maintaining their activity.

In fact, according to a report by Grand View Research, the global spray drying equipment market size was valued at over USD 4.5 billion in 2023 and is expected to grow at a CAGR of 6.8% through 2030. This growth is driven by the increasing demand for powdered food and pharmaceutical products.

Question:

Why is spray drying preferred over freeze drying in some industries?

Answer: Spray drying is faster and more cost-effective for heat-stable materials. While freeze drying preserves delicate biological compounds, spray drying offers higher throughput, making it ideal for food and chemical manufacturing.

Advantages of the Spray Drying Process

|

Advantage |

Description |

|

Speed |

Rapid drying within seconds, suitable for continuous production. |

|

Consistency |

Uniform particle size and moisture content. |

|

Scalability |

Applicable from laboratory-scale to industrial-scale production. |

|

Preservation |

Maintains product stability and extends shelf life. |

Challenges and Limitations

Despite its advantages, spray drying also presents some challenges. High energy consumption and potential heat degradation of sensitive compounds can be limiting factors. However, modern spray dryers are equipped with advanced control systems to minimize these effects. For example, multi-stage dryers allow for lower outlet temperatures, protecting heat-sensitive ingredients.

Question:

Can the spray drying process be environmentally friendly?

Answer: Yes. Many manufacturers now use energy recovery systems and closed-loop air circulation to reduce emissions and energy waste. Additionally, integrating renewable energy sources into drying operations further enhances sustainability.

Comparing Spray Drying with Other Drying Methods

When compared to methods like freeze drying or drum drying, spray drying stands out for its speed and scalability. However, each method serves specific needs. For instance, spray dryers are ideal for large-volume production, whereas freeze dryers are better suited for temperature-sensitive materials.

To learn more about the safety and efficiency of spray drying in food processing, visit our detailed guide on spray drying food safety.

Future Trends in Spray Drying Technology

With the rise of nanotechnology and biotechnology, spray drying is evolving to produce micro- and nano-sized particles with controlled properties. Researchers are developing low-temperature spray dryers and hybrid systems that combine spray drying with freeze drying for maximum efficiency and product quality.

According to data from the European Chemical Industry Council, innovations in spray drying are expected to reduce energy consumption by up to 25% by 2030, supporting global sustainability goals.

For additional insights into advanced drying systems, check out our article on milk powder spray dryers, which explores specialized applications in the dairy industry.

Conclusion

The spray drying process is a cornerstone of modern manufacturing, turning liquids into powders efficiently while preserving essential qualities. From food to pharmaceuticals, it ensures consistent quality and long shelf life. As technology advances, spray drying continues to become more energy-efficient, sustainable, and versatile.

In a world that demands convenience and quality, spray dryers will remain indispensable in shaping the future of powdered products.

Products

Products