Description

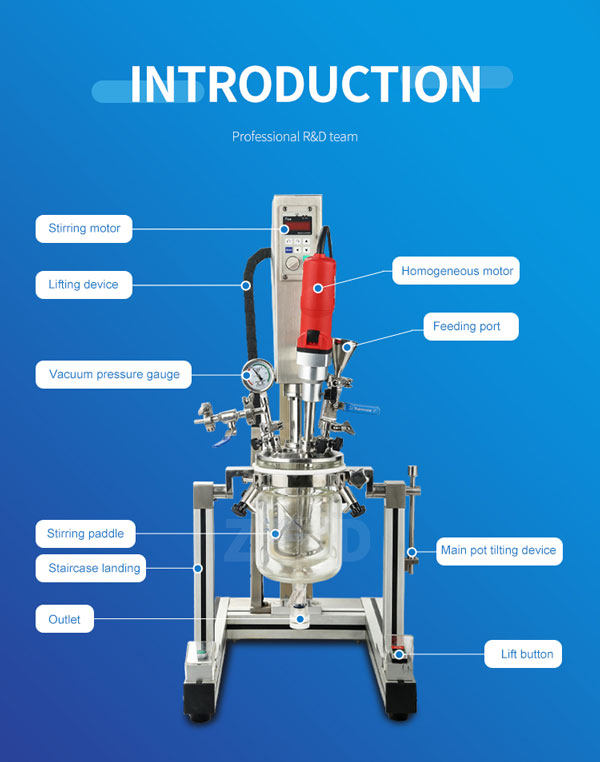

Introduction To Emulsification Tank

Emulsification tank is a kind of equipment for preparing emulsion, with capacity of 1L, 2L, 5L, 10L. They are often used in laboratories or small-scale production. The Emulsification tank consists of a container and a rotating agitator, usually a blade or rotor that rotates at high speed. During operation, the ingredients of the emulsion need to be added to the container, and then the agitator is started to make the liquid form an emulsion under high-speed shear. Because of its small size, simple operation, easy cleaning and maintenance, it is often widely used in laboratories and small-scale production in food, cosmetics, pharmaceuticals and other industries.

Advantages Of Emulsification Tanks

Good uniformity:

The emulsification tank can mix and disperse two or more immiscible liquids (such as water phase and oil phase) evenly to form fine droplets or particles, so that the emulsion has a fine texture and good uniformity.

The stirring paddle is equipped with anchor screws with a scraping impeller, and the uniform speed ranges from 10000 to 30000 (rpm).

High stability:

The emulsification tank can stably disperse the droplets or particles in the emulsion without stratification or precipitation, so that the quality of the emulsion is stable and not easy to deteriorate.

High productivity:

The emulsification tank can quickly prepare emulsions and has high production efficiency. Moreover, the emulsification tank can run continuously, and the production efficiency is higher.

The amount of emulsification ranges from 500ml to 10000ml.

Easy to use:

The emulsification tank is easy to operate, just pour the liquid to be mixed into the emulsification tank and turn on the mixer.

The lifting bracket stroke is 210mm.

Strong controllability:

The stirring speed, stirring time, temperature and other parameters of the emulsification tank can be adjusted according to the needs in order to obtain the desired emulsion.

The stirring speed range (rpm) is 0~230, the allowable ambient temperature is 5~40°C, and the allowable relative humidity is 80%.

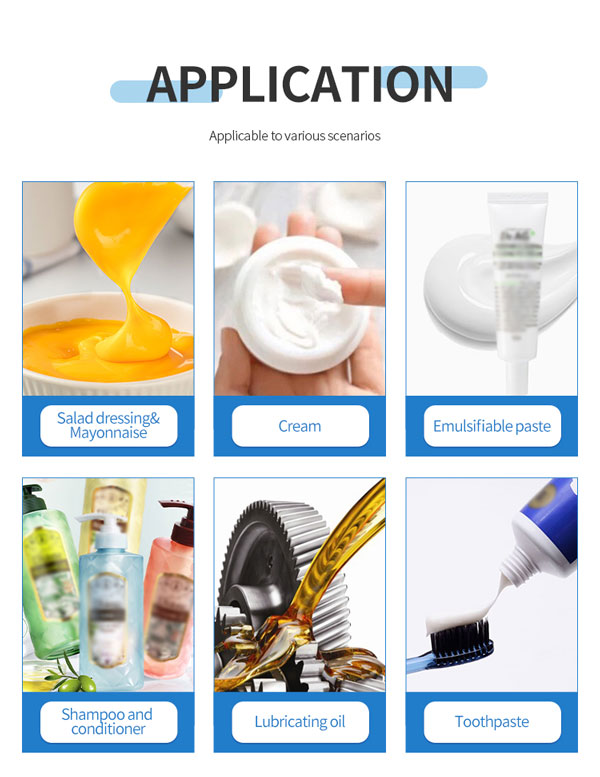

Application Of Emulsification Tank

Food industry:

The emulsification tank can be used to prepare various emulsions, such as salad dressing, mayonnaise, sauces, cream, fresh cream, etc. The emulsification tank can mix and disperse the water phase and the oil phase evenly, so that the emulsified liquid has a stable texture and taste.

Cosmetics industry:

Emulsification tank can be used to prepare various cosmetic emulsions, such as cream, body lotion, facial cleanser, mask, etc. The emulsification tank can mix and disperse the water phase and the oil phase evenly, making the cosmetic emulsion delicate and comfortable to use.

Pharmaceutical industry:

Emulsification tank can be used to prepare various emulsions and suspensions, such as vaccines, drugs, oral liquids, etc. The emulsification tank can disperse poorly soluble drugs in the water phase for easy administration and absorption.

Chemical industry:

Emulsification tank can be used to prepare various emulsions, such as latex, paint, resin, etc. The emulsification tank can mix and disperse different chemical components evenly, making the emulsion stable and easy to apply.

Detergent industry:

Emulsification tank can be used to prepare various detergents, such as washing powder, dishwashing liquid, detergent, etc. The emulsification tank can mix and disperse different chemical components evenly, so that the detergent has a good cleaning effect.

Emulsification Tank Maintenance

Regular cleaning:

After the emulsification tank is used for a period of time, some dirt will be deposited on the inner wall and the agitator, which will affect the working efficiency of the emulsification tank and may even cause failure. Therefore, the emulsification tank needs to be cleaned regularly.

Regular replacement parts:

Some key components in the emulsification tank (such as motors, bearings, etc.) will wear out after long-term use and need to be replaced regularly.

Regularly check lubrication:

The lubrication condition of the emulsification tank has a great influence on the operating efficiency and life of the equipment, so it is necessary to check the lubrication condition regularly and add an appropriate amount of lubricating oil.

Check circuit:

The circuit of the emulsification tank should be checked regularly to ensure that the circuit is unblocked and the electrical equipment is working normally.

Maintenance safety valve:

During the heating process of the emulsification tank, the internal pressure may increase, so it is necessary to install a safety valve, check and maintain it regularly.

To maintain the mixer:

The agitator of the emulsification tank is one of the key components, and it needs to be checked and cleaned regularly to ensure its normal operation.

FAQ

Q: What should i do if there is stratification in the emulsion?

A: It may be caused by uneven stirring, and the stirring speed and stirring time can be adjusted; it may also be that the formula is improper and needs to be changed, or the temperature may be inappropriate, and the temperature of the emulsion needs to be adjusted.

Q: What should i do if the color of the emulsion is uneven?

A: It may be that the proportion of ingredients is inappropriate or the formula is unreasonable. It is necessary to re-adjust the proportion of ingredients or change the formula; it may also be caused by too fast or too slow feeding speed, and the feeding speed needs to be adjusted.

Q: What should i do if there are bubbles in the emulsion?

A: It may be that the agitator is too fast, and the stirring speed needs to be slowed down; it may also be that the feeding speed is too fast, and the feeding speed needs to be slowed down; it may also be that the liquid level is uneven, and the liquid level needs to be adjusted.

Q: What should i do if the viscosity of the emulsion is too high?

A: It may be due to excessive addition of ingredients or unreasonable formula, and it is necessary to re-adjust the amount of addition or change the formula; it may also be that the temperature is not suitable, and the temperature of the emulsion needs to be adjusted; it may also be caused by uneven stirring, and the stirring speed and stirring time need to be adjusted .

Products

Products

Get Price

Get Price Send Email

Send Email