Spray drying atomization is one of the most fascinating and widely used processes in modern industrial drying technology. It transforms liquid materials into dry powders in a matter of seconds, offering unmatched speed and efficiency. This method is used in industries ranging from food and pharmaceuticals to chemicals and ceramics.

What Is Spray Drying Atomization?

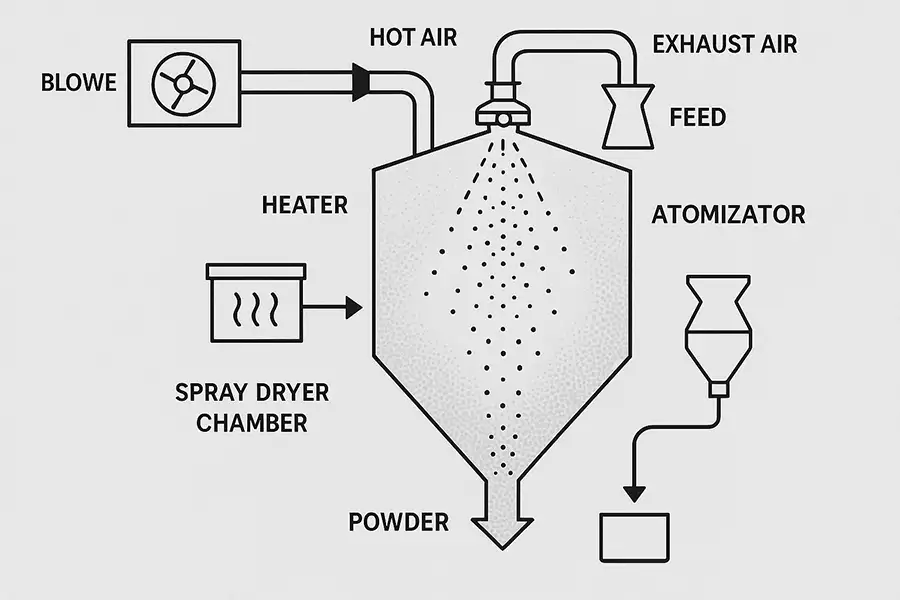

At its core, spray drying atomization involves converting a liquid feed into tiny droplets and exposing them to a stream of hot air. As the moisture evaporates, the solid particles are collected as a fine powder. This process is typically carried out in a spray dryer machine, which is designed to handle various materials efficiently.

According to a study by the University of Cambridge, spray drying is one of the most energy-efficient methods for producing dry powders from liquids, reducing production time by up to 60% compared to conventional drying techniques.

How Does It Work?

The process begins with the atomization stage. The liquid feed is pumped into the atomizer, where it is broken down into fine droplets. These droplets then enter a drying chamber filled with hot air. The moisture evaporates almost instantly, leaving behind dry particles that are collected at the bottom of the chamber.

There are several types of atomizers used in spray drying:

-

Pressure nozzles: Use high pressure to create fine droplets.

-

Rotary atomizers: Use centrifugal force for droplet formation.

-

Ultrasonic atomizers: Employ sound waves to generate mist-like droplets.

What determines the final particle size in spray drying?

Particle size is influenced by factors such as the atomizer type, feed concentration, air temperature, and drying chamber design. For example, rotary atomizers tend to produce finer and more uniform particles.

Applications Across Industries

Spray drying atomization has vast applications. In the food industry, it is used to produce milk powder, coffee, and instant soups. In pharmaceuticals, it helps create stable and easily dissolvable drugs. In chemical manufacturing, it is used for catalysts and ceramics.

To learn more about food-grade drying technologies, you can explore spray drying food safety standards and how modern spray dryers ensure hygiene and efficiency.

Spray Drying vs. Other Drying Methods

Compared to freeze drying or vacuum drying, spray drying offers faster results and is more suitable for large-scale production. Freeze drying, while excellent for preserving biological materials, takes longer and consumes more energy. If you’re curious about freeze drying, check out how to freeze dry candy using a machine for a comparison of drying technologies.

Can spray drying be used for heat-sensitive materials?

Yes, with controlled air temperature and specialized atomizers, spray drying can process heat-sensitive materials. Some advanced spray dryers use multi-stage drying systems to minimize thermal degradation.

Advantages of Spray Drying Atomization

Here are some of the major benefits:

-

Rapid drying within seconds

-

Uniform particle size distribution

-

Scalable for industrial production

-

Enhanced product stability and shelf life

-

Precise control over moisture content

According to data published by the International Journal of Food Engineering, spray drying can reduce microbial contamination by up to 95%, making it an ideal choice for food and pharmaceutical production.

Challenges and Innovations

Despite its advantages, spray drying also faces challenges like high energy consumption and equipment maintenance. Innovations such as energy recovery systems and AI-controlled atomization are helping overcome these issues. In fact, recent research from Stanford University predicts that automated spray drying systems could reduce operational costs by 40% by 2030.

How is spray drying technology evolving?

Modern spray dryers are now equipped with smart sensors and AI-based control systems to optimize droplet size, temperature, and airflow, ensuring consistent product quality and lower energy usage.

Conclusion

Spray drying atomization is a cornerstone of modern manufacturing, providing a fast, efficient, and scalable way to convert liquids into powders. From milk powder to pharmaceutical formulations, its versatility continues to drive innovation across industries. As technology advances, the future of spray drying will likely focus on sustainability, automation, and precision control.

For more insights into drying technologies, visit our comprehensive guide on milk powder spray dryers and explore how spray drying equipment is shaping the future of industrial processing.

Products

Products