Description

Product Description

10 liter rotary evaporator is mainly used for continuous distillation of a large amount of volatile solvents under reduced pressure. It can be used to separate and purify reaction products, for example: concentration of extract, and distillation of receiving liquid during chromatographic separation. During use, depressurize first, and then start the motor to rotate the distillation flask. After the end, stop the machine first, and then ventilate the atmosphere to prevent the distillation flask from falling off during rotation. Distillation requires a heat source, often equipped with a constant temperature water bath.

Working Principle:

The basic principle of 10 liter rotary evaporator is distillation under reduced pressure, that is, under reduced pressure, when the solvent is distilled, the distillation flask is continuously rotating. Structure: The distillation flask can be a pear-shaped or round-bottomed flask with a standard ground joint, connected to a decompression pump through a high-level reflux serpentine condenser, and the other opening of the reflux condenser is connected to a receiving flask with a ground joint. For receiving evaporated organic solvents.

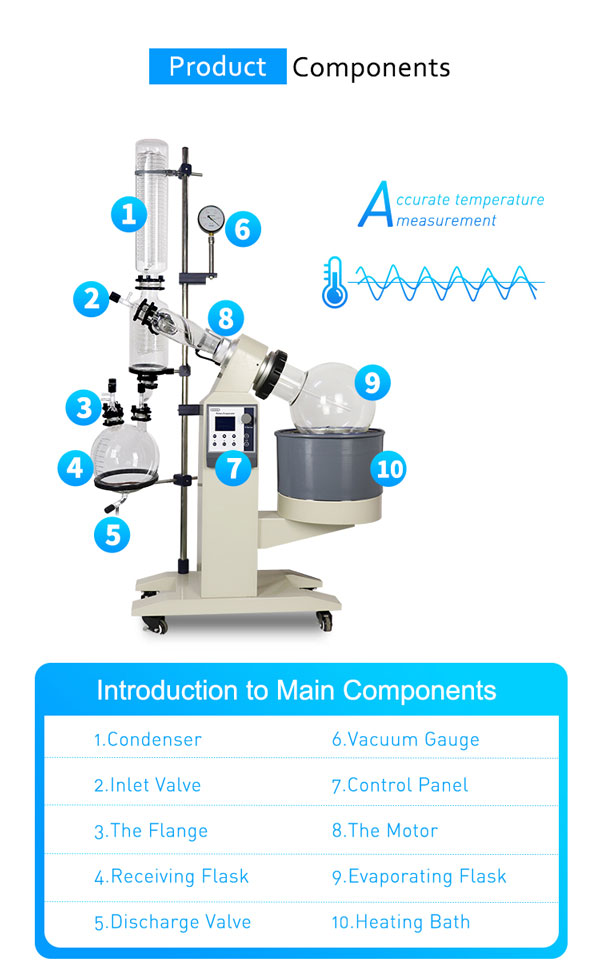

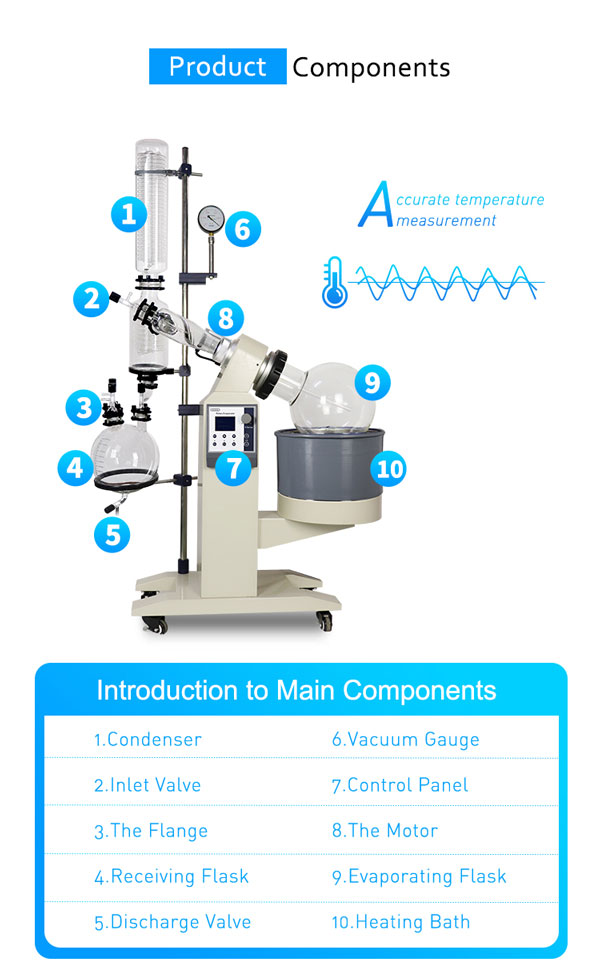

Product Structure

1. Rotate the motor to drive the evaporating flask through rotation.

2. Evaporation pipeline, the supporting shaft for the rotation of the evaporating flask, and the vacuum-sealed pipeline for extracting steam from the material.

3. Vacuum system reduces the pressure in the evaporator system and lowers the boiling point of the material.

4. Heating bath, water or oil is often used to heat the material.

5. The condenser, in order to speed up the condensation efficiency, is usually made into a double-snake surround type, and then add a condensing agent such as dry ice and acetone to condense the sample.

6. The condensed water collection bottle at the bottom of the condenser is used to capture the distilled solvent after recondensation and collect samples.

7. Lifting device, a mechanical or motorized mechanism that quickly lifts the evaporating flask from the heating bath.

Product Advantages And Features

1. It adopts the internationally advanced EL airtight system, which can maintain high vacuum. Gas-liquid separation, no reflux.

2. The 10 liter rotary evaporator adopts primary and secondary high-efficiency double condensers to ensure high recovery rate.

3. The rotating bottle is connected with nuts, which is convenient for loading and unloading. 10L and 5L rotary bottles are optional; Φ75 large diameter, hand can reach in and easy to clean, and can also be used

4. There is a liquid discharge valve at the bottom of the RE1002 collection bottle, so it is very fast to recover the dissolved coal.

5. The 10 liter rotary evaporator can feed continuously.

6. The vacuum system is equipped with a vacuum gauge, and the working vacuum can be adjusted for low boiling point materials.

7. The water bath of the 10 liter rotary evaporator is controlled by electronic constant temperature, and the water bath can be manually or electrically lifted,

8. Reasonable structure and exquisite materials. A large number of stainless steel and aluminum alloy parts are used in the mechanical structure. All glass parts are made of high temperature resistant borosilicate glass.

9. The key parts of electrical appliances are imported, and the Japanese Panasonic frequency conversion speed regulation is adopted, and the speed is digitally displayed. The wearing parts of rubber seals are all made of new materials, which is convenient for users to purchase and replace, and the key parts are imported.

Applications

10 liter rotary evaporator is specially selected for the concentration and purification of biological products that are easy to decompose at high temperature. It is mainly used for concentration, crystallization, drying, separation and recovery of dissolved coal in pharmaceutical, chemical and biopharmaceutical industries.

The RE series rotary evaporator produced by our company integrates the essence of similar products at home and abroad, and integrates our many years of successful practical experience, and has formed 2L, 3L, 5L, 10L, 20L, 50L series. The product design follows the principles of high efficiency, practicality and economy. Everything is for the sake of users.

Steps:

1. Turn on the condensing device of the rotary evaporator (condensed water or low-temperature circulating water bath)

2. Turn on the water bath and adjust the temperature

3. Turn on the circulating water of the vacuum pump and turn on the vacuum pump

4. Close the rotary steaming and degassing knob

5. Install the rotating bottle and adjust the height of the water bath (Note: Do not let go immediately after installing the rotating bottle, and then let go after reaching a certain negative pressure in the bottle, so as not to drop the rotating bottle; adjust the height of the water bath to make the rotating The gravity of the bottle is balanced with the buoyancy it receives to avoid breaking the rotating shaft due to excessive force)

6. When the white space is ≥0.04MPa, turn on the rotary button to adjust the speed

7. After the rotary steaming is finished, turn off the rotary button, open the air release knob, lower the water bath key, and remove the rotary bottle

8. Disposal of distilled solvent

9. Turn off the power of the water bath

10. Turn off the condensing unit

11. If no one else is using the vacuum pump, turn off the vacuum pump and its circulating water

Products

Products

Get Price

Get Price Send Email

Send Email