Description

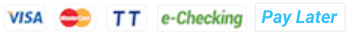

Micro Rotary Evaporator Introduction

N-1100D is a micro rotary evaporator with a capacity of 0.5-1L, ideal for small-scale experiments. Suitable for small-scale laboratory experiments, such as concentrating or purifying small amounts of solvents or samples. Commonly used in chemistry, biochemistry, pharmaceutical research and other fields that need to concentrate or separate liquids.

Structure Of Micro Rotary Evaporator

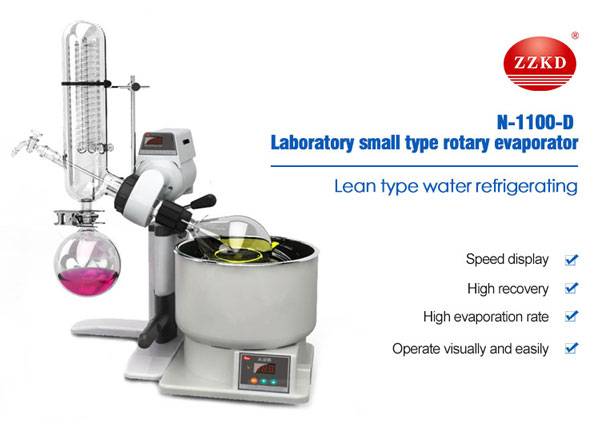

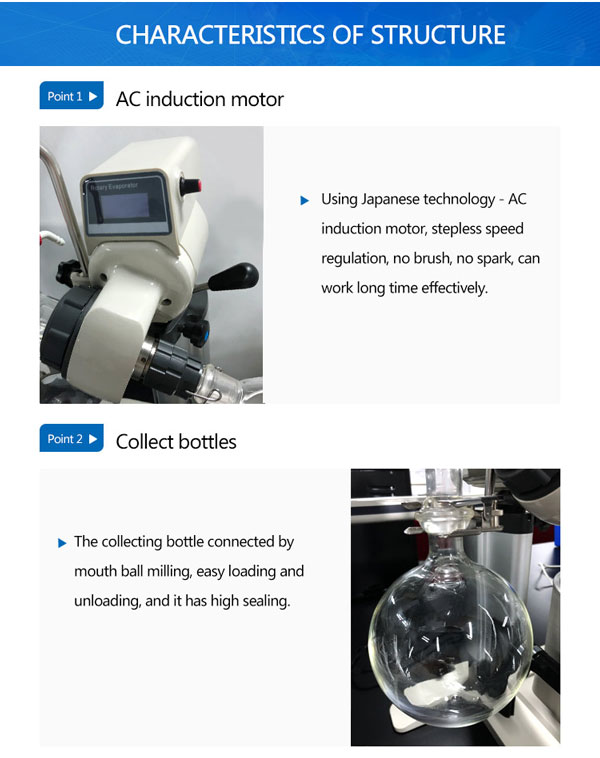

Motor:

Evaporating speed (ml/min): 20, the motor provides rotation power for the evaporating flask.

Evaporating flask:

0.5~1L, this is where the sample and solvent are placed for evaporation. Flasks are usually made of borosilicate glass for high temperature and chemical resistance.

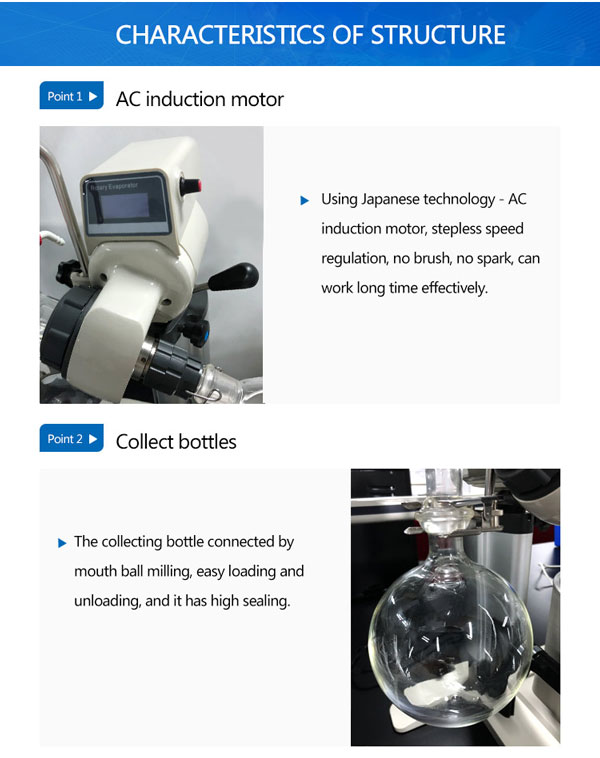

Heating bath:

φ260×140·7.4, the heating bath provides controllable temperature for the evaporating flask to evaporate the solvent. The temperature is usually controlled by a heating mantle or oil bath.

Condenser:

Lean type water refrigerating, the condenser is responsible for cooling the vaporized solvent and condensing it back to a liquid state. It usually consists of glass tubes, a water jacket and a cooling water supply.

Vacuum system:

A vacuum pump is used to maintain a low-pressure environment in the system, which reduces the boiling point of the solvent and facilitates evaporation.

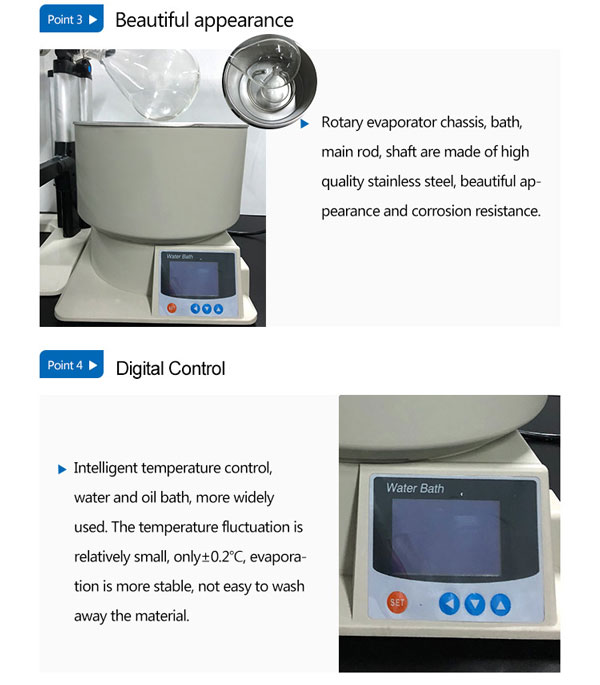

Control panel:

The control panel is used to adjust and monitor the parameters of the micro rotary evaporator such as temperature, rotation speed and vacuum pressure.

Features Of Micro Rotary Evaporator

Compact size:

Micro rotary evaporators are designed to be small and space-saving, making them ideal for use in small laboratories or workspaces.

Efficient evaporation:

These rotary evaporators are designed to evaporate small volumes of solvents quickly and efficiently, making them ideal for experiments that require rapid evaporation.

Precise temperature control:

Micro rotary evaporators typically come with a digital temperature controller that allows for precise temperature control, ensuring that the evaporation process occurs at the desired temperature.

Easy to use:

Micro rotary evaporators are designed to be easy to use, with simple controls and a user-friendly interface.

Versatile applications:

These rotary evaporators can be used for a wide range of laboratory applications, including solvent removal, concentration, and purification of natural products, essential oils, and other chemicals.

Safe and reliable:

Micro rotary evaporators are built to be safe and reliable, with features such as over-temperature protection and automatic shut-off in case of a malfunction.

Cost-effective:

Compared to larger rotary evaporators, micro rotary evaporators are generally less expensive, making them a cost-effective option for small-scale experiments.

Application Of Micro Rotary Evaporator

Chemical synthesis:

Micro rotary evaporators are commonly used in chemical synthesis to remove solvents or concentrate the final product.

Essential oil extraction:

Micro rotary evaporators can be used for the extraction of essential oils from plant material.

Pharmaceutical research:

Micro rotary evaporators can be used in pharmaceutical research for the purification of small molecules.

Food and beverage industry:

Micro rotary evaporators can be used in the food and beverage industry for the concentration of flavors and fragrances.

Environmental analysis:

Micro rotary evaporators can be used in environmental analysis for the concentration of samples prior to analysis.

Material science:

Micro rotary evaporators can be used in material science for the synthesis and purification of small molecules and polymers.

Cleaning Method Of Micro Rotary Evaporator:

1. General instruments and equipment can be brushed with water or soap solution from the outside to the inside to remove impurities, and then rinse the inner wall with distilled water or deionized water for two to three times. When cleaning glass instruments and equipment with grinding mouths, care should be taken to protect the grinding mouths.

2. Glass instruments are not easy to scrub with a brush, and are generally poured with detergent. Pour or suck into the container after soaking in water, then rinse with tap water and rinse with deionized water.

3. The sand core glass filter should be cleaned immediately after use. According to the sediment in the sand core, choose an appropriate detergent to dissolve the surface sediment, rinse it with distilled water, dry it at 110°C and store it in a dustproof cabinet.

Repair And Maintenance Of Rotary Evaporator

1. Before use, carefully check whether the glass bottle is damaged and whether the interface is consistent.

2. Wipe each contact surface with a soft cloth and apply appropriate amount of vacuum grease to prevent dust from entering.

3. Regularly loosen each interface to avoid the connector from being unable to rotate due to long-term locking.

4. First turn on the power switch, and then gradually increase the speed of the machine; after turning off the switch, first confirm that the experimental instrument has entered a standstill state.

5. The PTFE switches in each part should not be fastened with excessive force, as it is easy to damage the glass.

6. Avoid deforming the PTFE piston when standing still for a long time in the working state. After the machine stops, each PTFE switch can be tightened.

7. The sealing ring should be cleaned frequently.

FAQ

Q:Why is the evaporation rate slow?

A:Check the vacuum pump to make sure it is working properly and providing enough vacuum pressure.

Ensure the heating bath is at the correct temperature and is heating the evaporation flask evenly.

Check the condenser to make sure it is not clogged with debris, which could slow down the evaporation rate.

Q:Why is the vacuum pressure fluctuating?

A:Check for leaks in the system and tighten any connections that may be loose.

Ensure the vacuum pump is working properly and providing enough pressure to maintain a consistent vacuum level.

Check the vacuum valve to make sure it is not partially open, which could cause pressure fluctuations.

Q:Why is the sample splashing?

A:Make sure the sample is not overfilled in the evaporation flask.

Check the rotation speed and adjust it if necessary to reduce the splashing.

Ensure the sample is not boiling too rapidly, which could cause splashing.

Products

Products

Get Price

Get Price Send Email

Send Email