Choosing the right drying method can be tough. You might worry about damaging your product or not getting the results you need. Understanding your options clearly helps you make the best decision.

Yes, for many professional and industrial uses, a spray dryer is often better than a food dehydrator. It excels at turning liquids into fine, uniform powders quickly, especially for heat-sensitive materials, offering advantages in particle size control and production speed for labs and businesses.

You want the best way to dry your materials. Maybe you're in a lab, a growing business, or a large factory. Let's look closely at spray dryers and food dehydrators. This will help you see which one fits your work best, and I'll share some of my experiences as a manufacturer in this field.

How Exactly Do Spray Dryers and Food Dehydrators Dry Things Differently?

Drying seems simple, but the 'how' matters a lot. Using the wrong method can ruin your product or waste energy. Knowing the core difference helps you avoid these problems effectively.

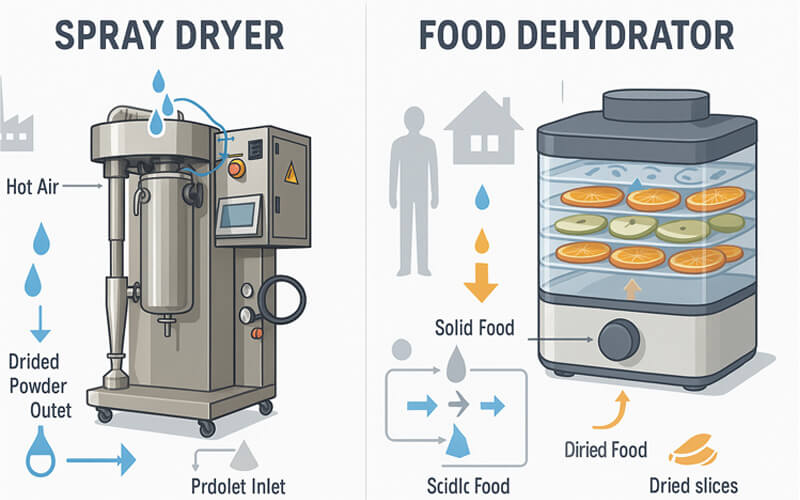

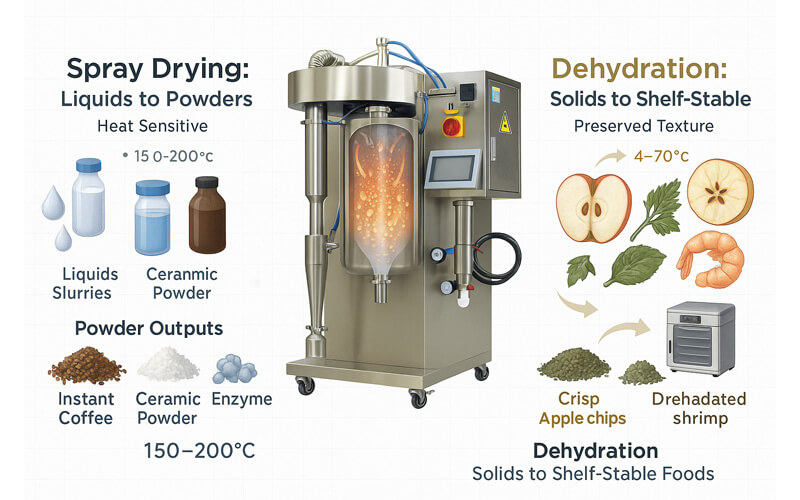

Spray dryers atomize a liquid feed into fine droplets and dry them with hot gas, creating a powder. Food dehydrators typically use heated air circulated over solid or semi-solid materials over a longer period to remove moisture. This basic difference impacts everything from product form to drying speed.

Let's break this down further so you can see the practical implications.

Spray Drying: The Atomization Advantage

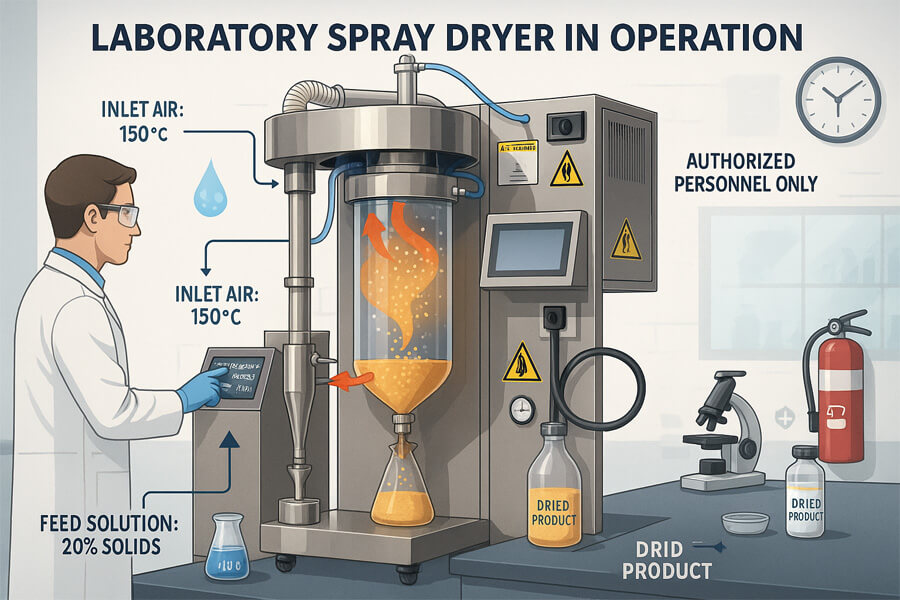

In my 16 years of experience manufacturing these machines, the heart of a spray dryer is its atomizer. This component takes your liquid sample – perhaps a solution, an emulsion, or a fine suspension – and disperses it into a mist of extremely small droplets. Imagine a very fine, controlled spray. These tiny droplets are then introduced into a chamber filled with hot drying gas. Because the droplets are so minute, they possess an enormous collective surface area. This vast surface area allows the moisture to evaporate almost instantly, often within a few seconds. The resulting dry particles, now a fine powder, are then efficiently separated from the drying air, typically using a cyclone separator. We've spent years perfecting our cyclone designs at Zhengzhou Keda to ensure maximum product recovery, which our clients really appreciate. This method is truly ideal for creating consistent, fine powders and is fundamental for many industries we support, such as pharmaceuticals needing precise particle characteristics and food ingredient companies aiming for instant solubility.

Food Dehydrators: Slow and Steady Heat

Food dehydrators, on the other hand, operate more like a very gentle, low-temperature oven. You typically place your material, which is usually in solid pieces like fruit slices, vegetable chunks, or herbs, onto trays. The dehydrator then circulates warm air, usually in the range of 50 to 70 degrees Celsius, around these pieces for an extended period. This can be many hours, or sometimes even a couple of days, depending on the moisture content and thickness of the material. The moisture slowly evaporates from the surface. This method is very common for home food preservation or for small-scale businesses making products like dried fruit snacks or jerky. While it's straightforward, it doesn't offer the sophisticated control over the final particle form that a spray dryer provides. You get dried, solid pieces, not a fine, engineered powder. For our B2B clients, such as chemical companies or research institutions that require powdered materials for their processes or products, a standard food dehydrator generally isn't the right primary processing tool, though it might have some very specific, niche applications.

So, the fundamental distinction is this: spray dryers rapidly transform liquids into powders; food dehydrators slowly dry existing solid or semi-solid materials into dried pieces.

What Types of Materials Are Best Suited for Spray Dryers Versus Food Dehydrators?

Your material is unique, and its specific properties will heavily influence the best drying method. Choosing incorrectly can lead to poor product quality, degradation, or even an unusable final product.

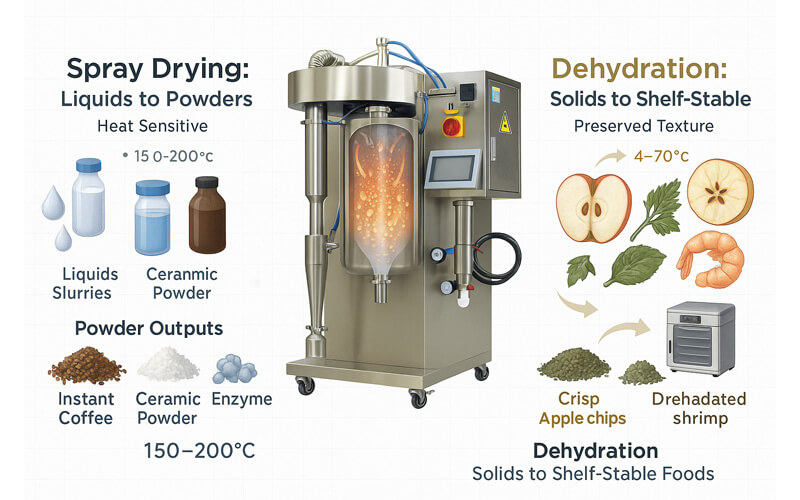

Spray dryers excel with liquids, solutions, emulsions, and pumpable slurries that need to be transformed into fine, uniform powders. They are especially good for heat-sensitive materials like pharmaceuticals, milk, enzymes, or instant coffee. Food dehydrators are ideal for drying solid foods like fruits, vegetables, meats, and herbs to preserve them by removing moisture.

The nature of your starting material is probably the biggest factor in choosing your drying equipment.

Spray Dryers: Unmatched Versatility with Liquids

At our company, Zhengzhou Keda, we see an incredibly diverse range of liquids being processed through our spray dryers. This is because if you can pump it and atomize it, you can likely spray dry it. Consider these examples from our global customer base:

-

Pharmaceutical Companies: Many active pharmaceutical ingredients (APIs) and excipients are heat-sensitive. Spray drying offers a way to dry them quickly at relatively low product temperatures, which helps preserve their chemical integrity and biological activity. We've collaborated with many pharmaceutical clients to achieve very specific particle sizes needed for tablets or inhalation products, which is critical for bioavailability. Our ISO9001 and CE certifications are vital for this sector.

-

Food & Beverage Industry: This is a huge area for spray drying. Think of milk powder, instant coffee, egg powders, food colorings, flavors, and encapsulated oils. The powder form improves shelf life, reduces transportation costs, and makes them easy to incorporate into other products. I remember a client in the natural flavorings sector who needed to encapsulate volatile aroma compounds to protect them – our spray dryer was the perfect solution.

-

Chemical & Materials Science Labs: Catalysts, detergents, pigments, advanced ceramics, polymers, and even nanoparticles can be produced as powders using spray drying. Our equipment is designed to handle a variety of solvents and chemical compositions. We even offer specialized units with inert loop systems for safe solvent recovery and processing of flammable materials, a common need for materials science researchers.

-

Biotechnology & Life Science Companies: Delicate materials like enzymes, proteins, microbial cultures, and yeasts can be gently dried into stable, easy-to-store powders while retaining their activity. We often work with research institutions and biotech startups on these challenging applications.

The key is starting with a liquid that can be atomized. If your material fits this description, then a spray dryer offers incredible potential.

Food Dehydrators: Best for Solid Chunks and Slices

Food dehydrators are much more limited in the types of materials they can handle effectively. They are primarily designed for:

-

Fruits and Vegetables: Slices of apples, bananas, mangoes, or vegetables like tomatoes, bell peppers, and mushrooms are typical. The goal is to reduce moisture for preservation.

-

Meats and Fish: For making jerky or dried fish, where the texture of the dried solid is important.

-

Herbs and Spices: To preserve fresh herbs like basil, oregano, or mint for later culinary use.

You cannot typically put a liquid solution, like a pharmaceutical formulation or a chemical precursor solution, into a standard food dehydrator and expect to get a fine, usable powder. You'll most likely end up with a sticky residue, a hard film, or an unevenly dried mass. While some heavy-duty dehydrators might handle thick purees, they won't produce the distinct, free-flowing, and often engineered particles that a spray dryer is designed to create. This is a critical difference for many of our industrial and research customers who need specific powder properties.

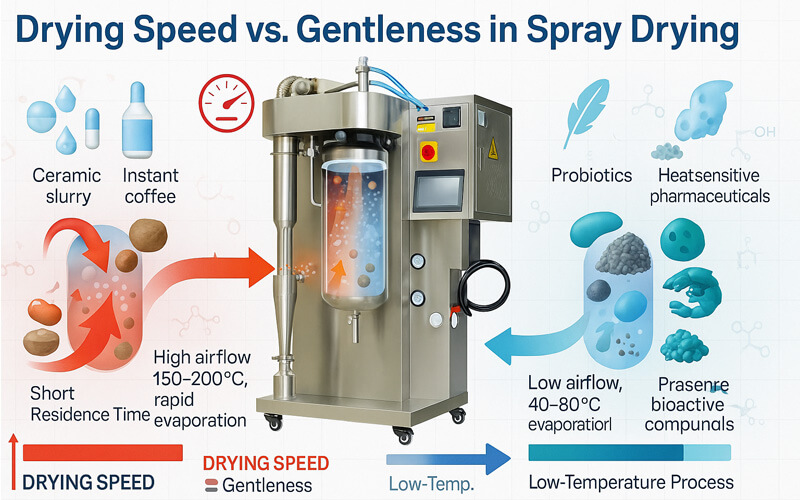

When It Comes to Speed and Gentleness, Which Dryer Has the Edge?

In any production or research setting, time is a valuable resource, and maintaining product quality is absolutely essential. Slow or harsh drying processes can degrade your materials and impact your efficiency.

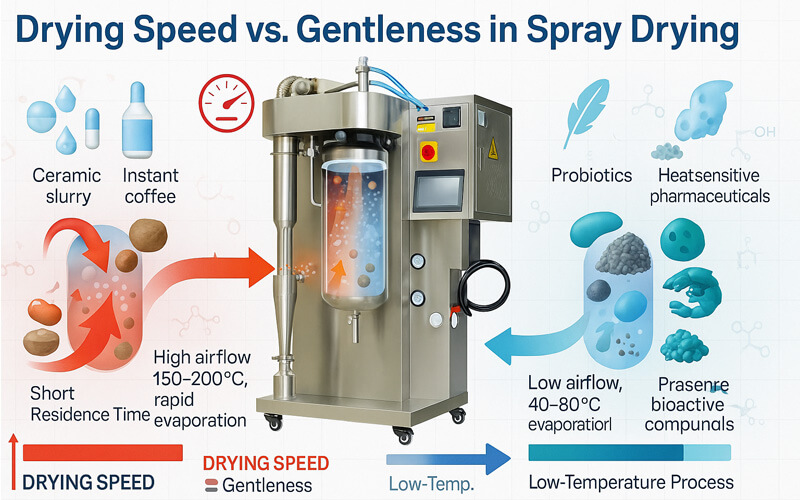

Spray dryers offer significantly faster drying times, often completing the process in mere seconds, due to highly efficient atomization and heat transfer. This rapid process is also surprisingly gentle, as the product's core temperature remains relatively low despite high inlet air temperatures, effectively protecting heat-sensitive materials. Dehydrators, in contrast, are much slower.

This aspect of speed and gentleness is where spray dryers truly demonstrate their advantages, especially for the demanding applications of our B2B clients.

Speed: Spray Dryers are in a League of Their Own

A spray dryer works with incredible speed. The liquid feed is atomized into a cloud of tiny droplets, and these droplets dry almost instantaneously as they come into contact with the hot drying gas passing through the chamber. We are talking about a residence time – the time the particle is actually drying – of just a few seconds. I have personally seen our laboratory-scale spray dryers convert several liters of a solution into a fine, dry powder in less than an hour. For our industrial clients using larger, continuous operation units, this means a very high throughput, processing substantial volumes of liquid feedstock efficiently. This speed is a massive operational advantage in commercial production settings where output and efficiency are key performance indicators.

A food dehydrator, by comparison, is typically a batch process that takes many hours to complete. Depending on the material, its moisture content, and its thickness, drying can take anywhere from 8 to 24 hours, or sometimes even longer. This pace is acceptable for home use or very small-scale artisanal production, but it is generally too slow for most industrial manufacturing or time-sensitive research needs where quick results or high output volumes are required.

Gentleness: The Surprising Protective Nature of Spray Drying

It might seem a bit strange that spraying a liquid into very hot air (our spray dryer inlet temperatures can range from 120°C to 300°C, and sometimes even higher for specific materials) is considered a gentle process, but it is. Here’s the science behind it:

-

Evaporative Cooling Effect: As moisture rapidly evaporates from the surface of each tiny droplet, it creates a significant cooling effect on the particle itself. This is similar to how sweating cools your body. So, even though the drying air is hot, the actual temperature experienced by your product particles stays much lower, often well below temperatures that would cause degradation. For many of our clients in the pharmaceutical and biotech sectors, this is absolutely critical for preserving the activity of sensitive compounds like proteins, enzymes, or vitamins.

-

Extremely Short Heat Exposure Time: Even if the particle temperature does rise slightly towards the end of the drying process, it is only exposed to this temperature for a very, very short duration – mere seconds. This minimal exposure time significantly reduces the risk of thermal degradation.

We frequently work with customers who need to dry materials that would be completely denatured or destroyed by the prolonged heating periods typical in a conventional oven or a standard food dehydrator. For example, many delicate starter cultures used in the food industry are successfully spray dried. In contrast, food dehydrators, while generally using lower air temperatures, expose the material to that heat for a very long time. This prolonged exposure can lead to undesirable changes such as degradation of color, loss of flavor, destruction of nutrients, or reduced activity of important compounds in sensitive materials. We always stress the importance of rapid drying and short heat exposure when discussing drying solutions with our clients who handle delicate products.

For Labs and Businesses, Which is More Practical: Spray Dryers or Dehydrators?

Your laboratory or business facility has very specific operational needs concerning scale, process control, and the desired form of the final product. Choosing drying equipment that doesn't align with these needs can mean a wasted investment and ongoing operational headaches.

For laboratories and businesses that require controlled powder production, precise particle engineering capabilities, potential for scalability, and options for continuous operation, spray dryers are far more practical and versatile. Food dehydrators are simpler but are generally limited to small-scale batch drying of solid materials, lacking the advanced process control needed for specialized powder applications.

When we move from home use to professional environments like research labs or industrial production, the practical requirements for equipment change significantly.

Spray Dryers: Engineered for Professional and Industrial Applications

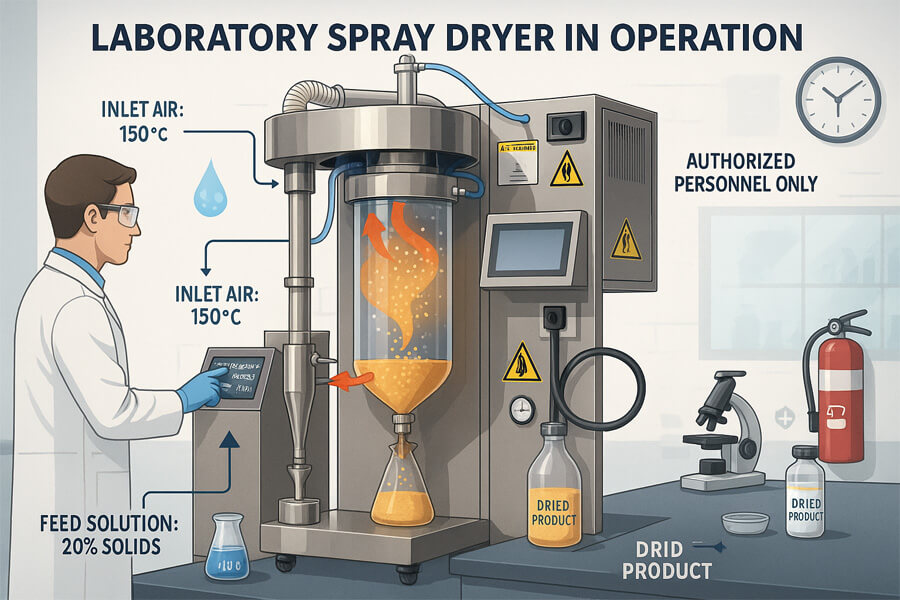

As a company specializing in R&D and production of laboratory instruments for over 16 years, our ZZKD spray dryers, available from compact lab-scale units to larger pilot and production systems, are specifically built to meet the rigorous demands of research and industry. Here’s why they are more practical for these settings:

-

Particle Engineering and Control: Spray drying offers remarkable control over the final product's particle size, morphology (shape), bulk density, and residual moisture content. This is achieved by carefully adjusting operational parameters like inlet air temperature, liquid feed rate, atomization pressure or speed, and nozzle type. This level of control is absolutely crucial for our clients in the pharmaceutical industry (e.g., for formulating drugs for inhalation that require specific particle sizes) or in materials science (e.g., for creating catalysts or ceramic powders with defined surface areas and structures). I recall assisting a prominent research institution in optimizing their spray drying parameters to achieve a very specific powder flowability for a novel advanced material they were developing.

-

Scalability of Process: Processes and formulations developed and optimized on a lab-scale spray dryer can often be confidently scaled up to our pilot-scale or full industrial production units. We design our equipment range to facilitate this smooth transition, which is a huge benefit for our customers as their production needs grow or they move from R&D to commercialization. This kind A-Z solution and scalability is something a food dehydrator simply cannot offer for powder production.

-

Potential for Continuous Operation: Many of our industrial spray dryer models are designed for continuous, 24/7 operation, making them ideal for large-scale manufacturing in industries like food processing or chemical production. This continuous capability is a major advantage for our B2B clients focused on high-volume output.

-

Versatility in Feedstock: Spray dryers can handle a wide array of feedstocks, including solutions, suspensions, emulsions, and fine slurries. They can be adapted for an extensive range of products across diverse industries. Our engineering team, with many English-fluent members, often works on customizing units for specific, challenging applications our clients bring to us.

-

Containment, Safety, and Environmental Considerations: For processing valuable, hazardous, or oxygen-sensitive materials, or when using organic solvents, spray dryers can be configured as closed-cycle systems. These systems allow for efficient solvent recovery and operation with inert gases like nitrogen, ensuring operator safety, product integrity, and environmental protection. This is a frequent and critical requirement from our chemical and pharmaceutical customers, and we have extensive experience in providing these solutions.

Food Dehydrators: Simpler by Design, but Limited in Scope

Food dehydrators are, by their nature, generally much simpler machines. They perform their basic function of moisture removal from solid pieces effectively on a small scale. However, they lack the sophisticated process controls and engineering capabilities inherent in a spray dryer. With a dehydrator, you cannot really control particle size or morphology because you are not fundamentally creating particles in the same engineered sense. Scaling up production with dehydrators often just means acquiring more individual small units, which is not an efficient or practical approach for industrial-scale powder production. For a research lab that needs to produce a specific type of powder with consistent characteristics for experiments or further development, a food dehydrator would typically not be the appropriate choice. It functions more as a preservation tool for existing solids rather than a production or particle engineering instrument. For example, our clients in the rapidly growing cannabis and hemp processing sector would use extraction techniques, followed by solvent recovery using rotary evaporators or falling film evaporators, and then purification via short-path distillation. If a powdered form of an extract or isolate was the desired final product, spray drying would be the advanced technology they would consider, not a simple food dehydrator.

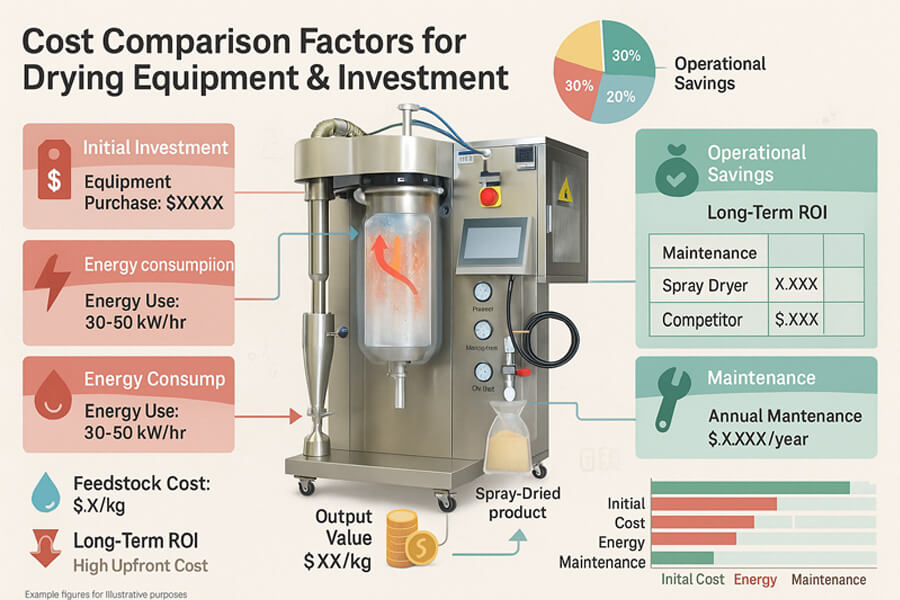

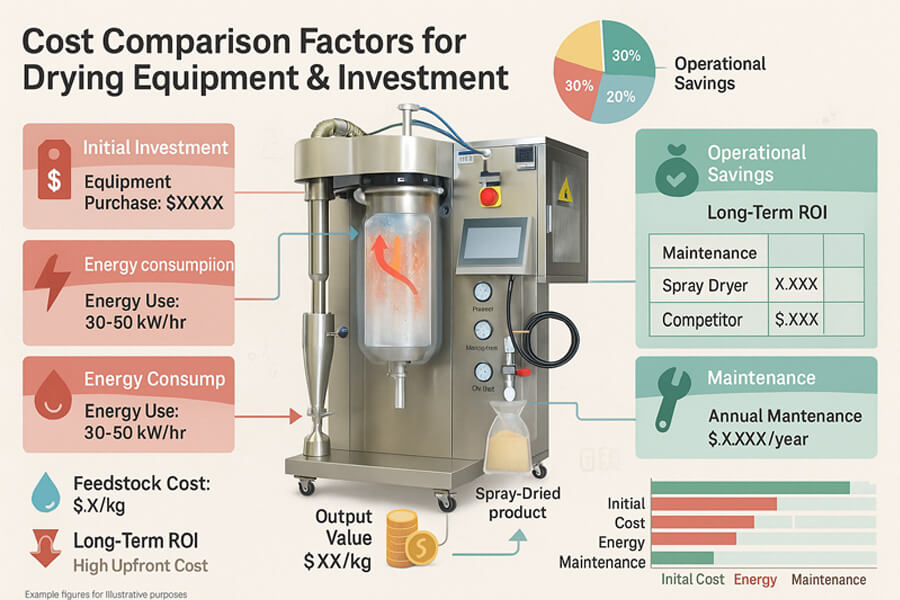

What About the Investment and Running Costs for Spray Dryers vs. Dehydrators?

Budget is always a significant consideration, both for the initial purchase price of equipment and for its ongoing operational expenses. Making an uninformed decision in this area can put a substantial strain on your finances.

Spray dryers generally have a higher initial investment cost compared to basic food dehydrators, reflecting their more advanced technology, precision engineering, and broader capabilities. However, for industrial-scale or specialized laboratory applications, their efficiency, high throughput, and unique product-forming capabilities often lead to better long-term value and a more favorable return on investment.

Let's be direct about the costs involved, as this is a major decision-making factor for all our customers, from university labs to large manufacturing plants.

Spray Dryers: An Investment in Advanced Capability and Efficiency

Yes, it is true that a laboratory-grade or industrial-scale spray dryer represents a more significant upfront capital investment when compared to a simple food dehydrator. This price difference is because spray dryers are considerably more complex machines, incorporating sophisticated components and systems, such as:

-

Precision-engineered atomizers (e.g., two-fluid nozzles, rotary atomizers) designed for specific droplet size distributions.

-

Advanced temperature, airflow, and feed rate control systems, often managed by PLCs (Programmable Logic Controllers) for automation and reproducibility.

-

Drying chambers constructed from high-quality materials, frequently stainless steel (e.g., SS304, SS316L) to ensure durability and product purity.

-

Efficient product collection systems, including high-performance cyclones and sometimes secondary collectors like bag filters or wet scrubbers.

-

Comprehensive control panels with user-friendly interfaces, data logging capabilities, and robust safety features.

As a manufacturer with over 16 years of dedicated production and export experience, we at Zhengzhou Keda Machinery and Instrument Equipment Co., Ltd. (ZZKD) are committed to providing high value-for-money products. Our equipment meets stringent international standards and is backed by certifications like ISO9001 and CE, assuring quality and reliability. The running costs for a spray dryer will naturally depend on its scale, the specific application, and the duration of use. Energy consumption for heating the drying air is a primary operational cost. However, the remarkable speed and efficiency of spray dryers, especially in continuous industrial operations, can translate to lower per-unit production costs for the right applications. More importantly, the ability to create unique, high-value powdered products with specific characteristics – products that often cannot be made effectively by any other method – frequently justifies the initial investment many times over. Furthermore, we pride ourselves on our "Worry-Free Global After-Sales" support, which includes a 24/7 global hotline with prompt response times, a comprehensive one-year warranty with free maintenance, and lifetime cost-price service for parts and technical assistance. This commitment helps minimize our customers' maintenance costs and operational downtime.

Food Dehydrators: Lower Initial Cost, Different Scope of Value

Food dehydrators, particularly those designed for home use or light commercial activities like small cafes or cottage industries, are significantly less expensive to purchase. They are much simpler in their construction and operation, typically consisting of a heating element, a fan, and trays. Their running costs are mainly the electricity required for the heater and fan. However, because they usually need to run for very long periods (many hours per batch), the cumulative energy consumption per batch can be notable. It is absolutely crucial, though, to compare these two types of equipment based on their intended purpose and capabilities. If your primary goal is to produce a specific type of powder with controlled particle characteristics, or to dry large quantities of liquid feedstock rapidly and continuously, a food dehydrator is not a viable alternative to a spray dryer, regardless of its lower initial price. The true value of a spray dryer is derived from its unique processing capabilities, its efficiency in professional settings, and its ability to generate products that meet specific quality and performance criteria. We often advise potential customers to thoroughly consider the total cost of ownership (TCO) and, most importantly, their specific product requirements and business objectives. If a simple dehydrator can genuinely achieve the desired outcome, then it may be a suitable choice. But if you need the specialized output, control, and scalability that a spray dryer offers, investing in the right equipment from the outset is ultimately more economical and strategically sound in the long run than attempting to make do with an inadequate or unsuitable machine. We believe strongly in transparency and building long-term trust, and we always welcome technical exchanges and factory visits to help customers make the most informed decision for their needs.

Conclusion

In short, for specialized powder production, enhanced speed, and the gentle drying of liquids into fine particles, a spray dryer is generally the superior choice. Food dehydrators are better suited for simpler, solid-drying tasks on a smaller scale.

Products

Products