Description

Product Description

20L rotary evaporator is a device that uses a rotary evaporator (flask) to increase the evaporation area and place it in a water bath under reduced pressure while rotating while heating, so that the solution in the bottle diffuses and evaporates. It is an ideal basic instrument for chemical industry, pharmaceutical industry, colleges and scientific research laboratories and other units to use in manufacturing and analysis experiments for concentration, drying, and recovery.

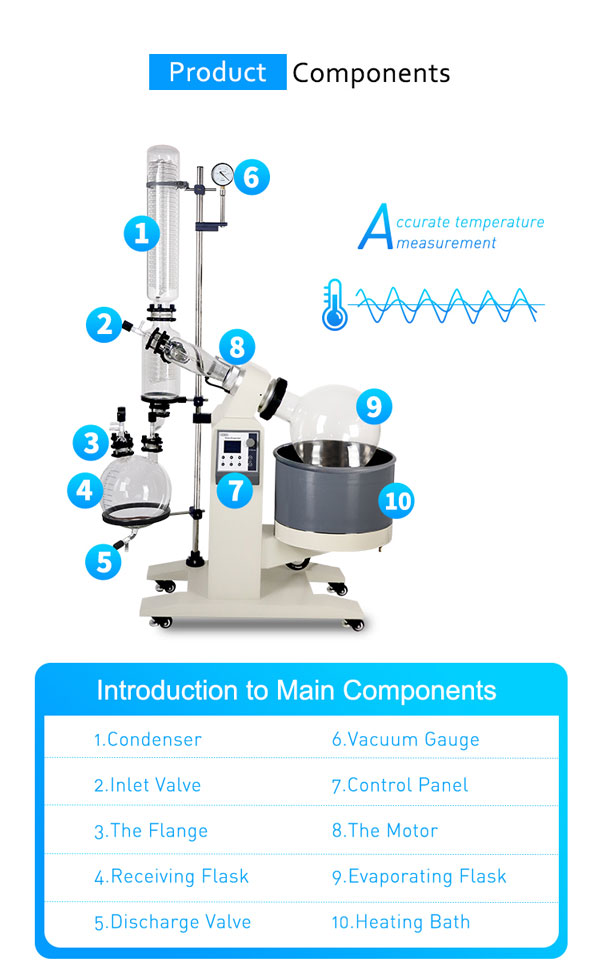

Product Structure

1. Host part: The transmission system imported from abroad has a reasonable structure and strong practicability.

2. Temperature control part: introduce foreign frequency conversion control system and temperature control system to ensure the performance of the instrument.

3. Water bath: the imported stainless steel plate is punched and formed at one time, and the vertical automatic lifting.

4. Sealing parts: The latest foreign PTFE material is selected and processed by special technology to enhance sealing, anti-corrosion and safety.

5. Main structure: Aluminum alloy and stainless steel materials are used to improve and improve the reasonable performance of the instrument

6. The standard configuration of the factory is a collection bottle (feedable type) 10L, a rotary bottle 20L

Factors Influencing Distillation Efficiency

Vacuum degree of 20L rotary evaporator

①20L rotary evaporator is composed of vacuum pump and its pipeline, evaporating flask and receiving flask, condenser tube and other components. Among them, the key factors affecting the vacuum degree are: vacuum pump power, airtightness of the system

②The lower the limit of the vacuum pump, the lower the vacuum value of the system. The two factors of the 20L rotary evaporator's equipment pressure resistance and avoidance of bumping determine the vacuum value that the system can form.

③Sealing ring: Common materials are PTFE and rubber. In terms of wear resistance and corrosion resistance, PTFE is superior to rubber.

Heating power of 20L rotary evaporator

The distillation rate is proportional to the temperature of the oil bath, that is, the higher the temperature, the faster the distillation rate. But in the actual process, the distillation rate cannot be accelerated by setting a high temperature. Reasons include:

① If the distilled substance is a heat-sensitive substance, it is easy to decompose and deteriorate at high temperature;

②Excessively high temperature will easily lead to high-temperature softening of sealing rings and other components, reducing their service life and reducing the airtightness of the system. Usually, the oil bath is heated by a water bath, and the temperature is set below 60°C. If the temperature is higher than 80°C, an oil bath is used for heating.

Motor speed

The faster the motor speed, the larger the infiltration area in the evaporating flask, the larger the heating area, the thicker the thickness of the formed liquid film, the larger the heat transfer temperature difference, and the higher the distillation efficiency. In actual use, the faster the speed, the better. It is mainly due to:

①The faster the rotation speed, the greater the centrifugal force formed, which will easily lead to bottle drop;

② The viscosity of the material is different, and there is an investigation of the rotational speed.

Cooling system

Better distillation efficiency, the temperature difference between the cooling system and the heating pot is maintained at 40°C, so as to quickly condense the formed hot steam and reduce the impact of steam on the vacuum of the system. The commonly used cooling medium is circulating condensed water. If there is a substance with a particularly low boiling point, an ice-water bath or an ice-ethanol bath using a circulating refrigerator as a carrier is also a common choice.

Usage notice

1. The unique PTFE combination valve can control the air flow and liquid flow arbitrarily, and can feed and discharge materials without stopping the machine to improve work efficiency.

2. The introduction of foreign advanced traditional system, reasonable structure, stable speed, no impact, durable, and strong practicability. Both frequency conversion control system and temperature control system adopt foreign technology to ensure the accurate performance of the instrument.

Set up:

1. Choose a volumetric flask that is approximately twice the starting volume.

2. Select and connect a vacuum pump that achieves the required vacuum level and is compatible with your specific solvent vapor.

3. Choose the right temperature for your water bath. A lower temperature will result in slower processing, but will also reduce the possibility of shock or damage to the sample due to overheating.

Start the rotary evaporation:

1. Turn on the cooler and let the temperature reach the set value.

2. Turn on the water bath and let the water bath reach the set point before starting to evaporate.

3. Fix the evaporating flask with clips. Do not rely on vacuum to fix the evaporating flask unless you are absolutely sure.

4. Begin to spin the flask fast enough to form a uniform coating on the inside surface of the flask.

5. Turn on the vacuum pump, close the stopcock on the condenser, and make the sample rotate in vacuum for about 1 minute. The sample may begin to boil, if the sample begins to boil vigorously or boil, the system will need to be vented and the vacuum set point adjusted.

6. Once boiling has ceased and solvent has accumulated in the solvent trap, lower the flask to half a hot tub.

7. Since the pump has fast and precise response capability, it is better to control the production process by adjusting the vacuum degree.

Stop rotary steaming work:

1. Lift the flask out of the hot tub.

2. Open the stopcock on the condenser to vent the system to atmosphere.

3. Turn off the rotation.

4. Turn off the vacuum power.

5. Remove the evaporating flask and solvent collection bottle and clean them.

6. Turn off the water bath and cooler.

Products

Products

Get Price

Get Price Send Email

Send Email