Rotary evaporators (rotovaps) are core equipment for concentration, solvent recycling and extraction. This article breaks down what really drives rotary evaporator price and how to choose the right size – using real specification data from 2 L to 50 L models.

1. What a Rotary Evaporator Actually Does (and Why It Matters for Price)

A rotary evaporator is designed to remove volatile solvents gently and efficiently. By rotating the flask in a heated water or oil bath under vacuum, it increases surface area and lowers the boiling point of the solvent. This is essential in:

-

Concentrating reaction mixtures or natural extracts

-

Recovering expensive or hazardous solvents for reuse

-

Purifying intermediates in pharmaceutical and fine chemical synthesis

-

Preparing samples in food, flavor and fragrance labs

Evidence of impact: A survey published in the journal Chemical Engineering & Technology reported that labs using modern solvent recovery equipment, including rotovaps, reduced fresh solvent consumption by up to 60–80 % over several years. That saving usually dwarfs the initial rotary evaporator price.

Is a higher rotary evaporator price always linked to better performance?

Not always. Above a certain basic quality level, price differences are mostly driven by evaporation capacity (flask volume, heating power), automation (electric lift, digital control) and materials (for aggressive solvents). An expensive device with the wrong size or features can be less “effective” for a specific lab than a mid-range model that matches real needs.

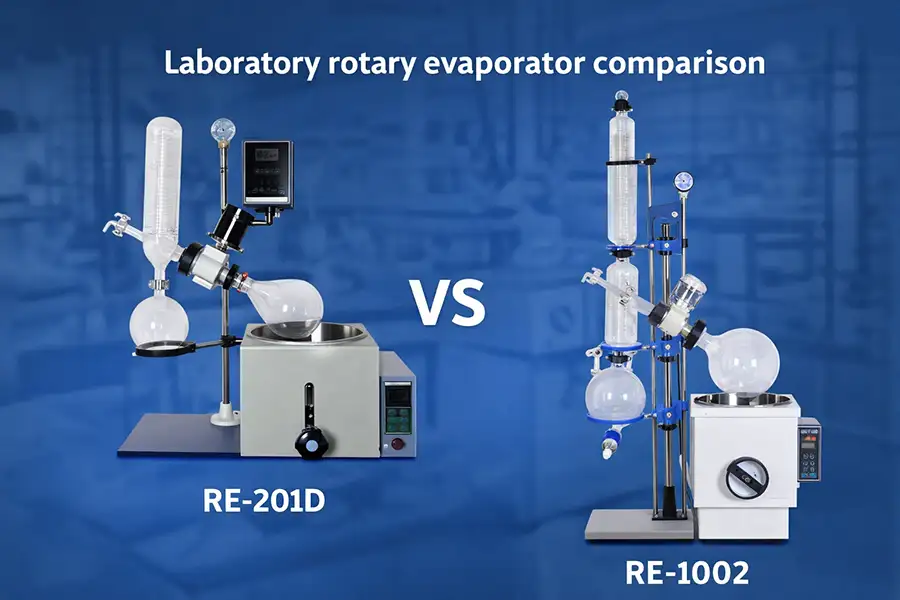

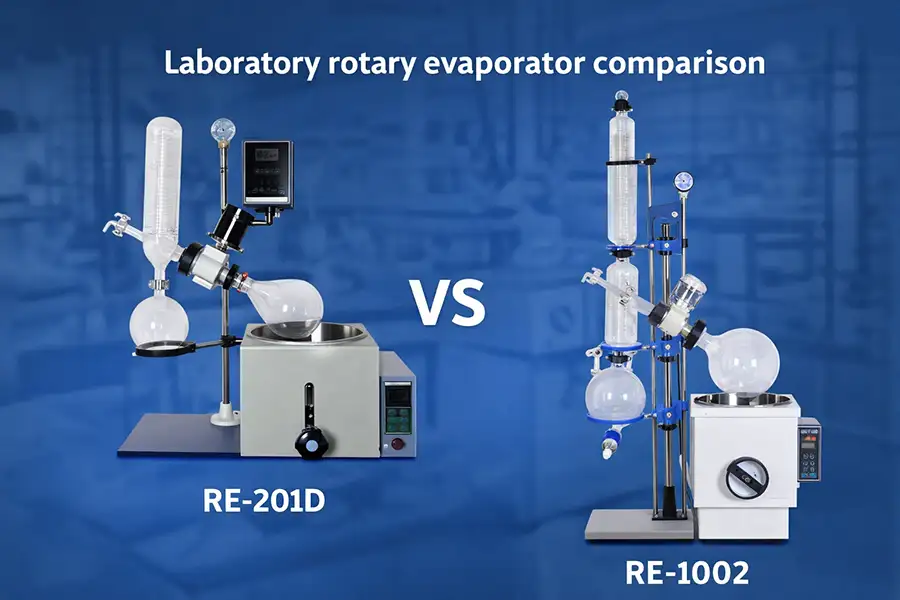

Typical lab rotary evaporator setup with water bath, condenser and receiving flask.

2. Key Specifications That Influence Rotary Evaporator Price

Instead of comparing brands only by list price, it is more useful to look at a few technical parameters that strongly correlate with both cost and practical performance.

2.1 Flask volume and evaporation rate

The evaporating flask volume is the most obvious driver of rotary evaporator price. Based on the data from our lab-scale series:

Representative Bench-Top Models (RE Series)

|

Model |

Evap. Flask |

Receiving Flask |

Bath Power |

Evap. Rate (H₂O) |

|

RE-201D |

2 L |

1 L |

1200 W |

> 1 L/h |

|

RE-301 |

3 L |

2 L |

1500 W |

> 1.5 L/h |

|

RE-501 |

5 L |

3 L |

1500 W |

> 1.5 L/h |

← Swipe Left and Right to View the Table→

Moving from 2 L to 5 L increases throughput and requires a more robust structure and heating system. This alone can move the rotary evaporator price from “entry lab” to “advanced lab” level. For solvent-intensive work, that jump often pays back quickly.

2.2 Heating power and temperature control

All three bench-top models above share an intelligent digital controller, with:

Higher-power baths (for larger units) heat up faster and maintain stability with heavy loads, but they increase both purchase price and running cost. For heat-sensitive samples, precise control is more important than maximum temperature.

2.3 Vacuum performance and sealing

Efficient evaporation requires good vacuum. For the RE-201D / RE-301 / RE-501 series:

This vacuum level allows low-temperature evaporation of most organic solvents. More advanced chemical-resistant sealing systems and integrated vacuum controllers add cost but reduce maintenance and improve reproducibility.

2.4 Lifting mechanism and ergonomics

Manual lifts are standard on small units. On larger systems, electric lift significantly improves ergonomics and safety when handling heavy 10–50 L flasks.

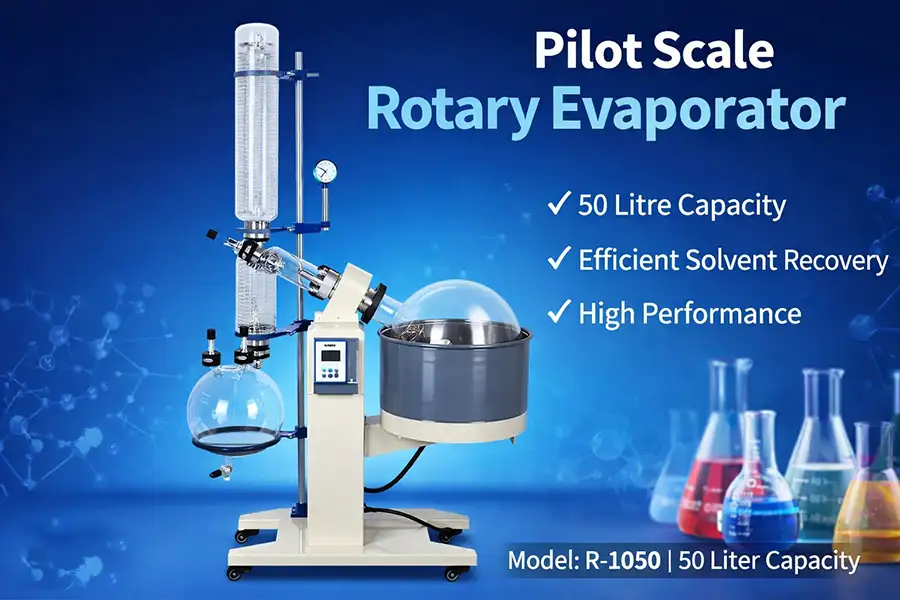

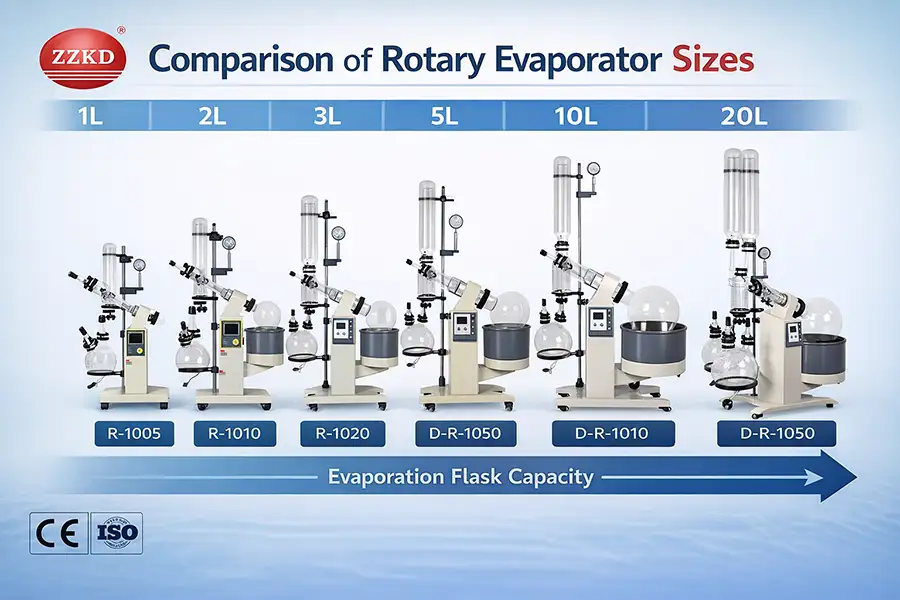

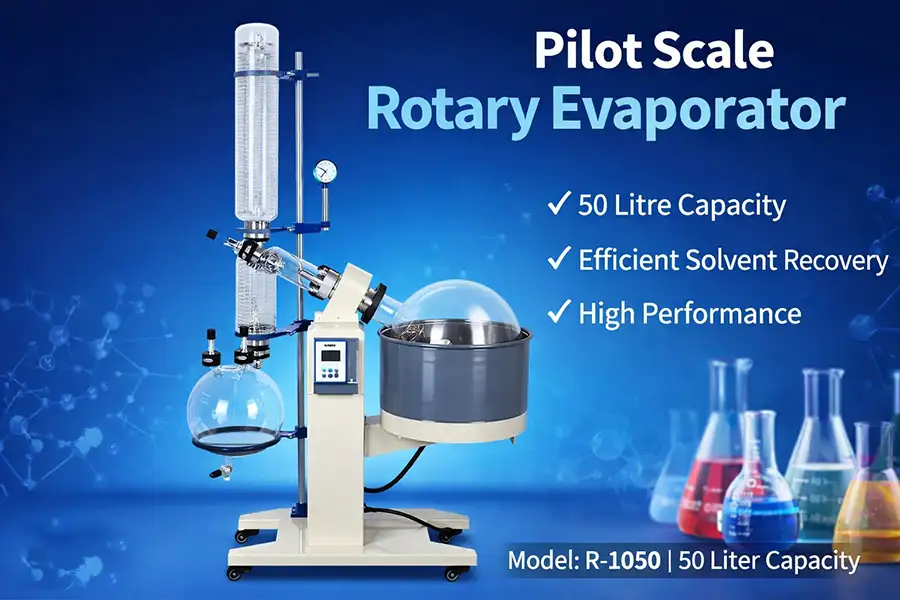

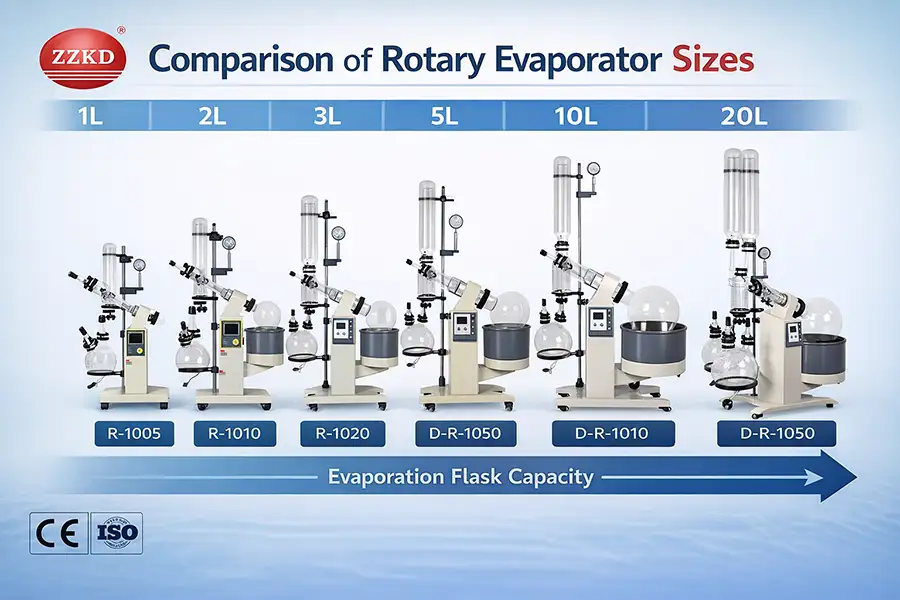

Pilot-Scale Models (R Series)

|

Model |

Flask Volume |

Motor |

Bath Size (mm) |

Lift Type |

|

R-1005 |

5 L |

40 W |

Φ300×170 |

Electric lift (0–150 mm) |

|

R-1010 |

10 L |

Brush-less 250 W |

Φ350×220 |

Electric + hand (0–160 mm) |

|

R-1020 |

20 L |

Brush-less 250 W |

Φ450×260 |

Electric + hand (0–190 mm) |

|

R-1050 |

50 L |

Brush-less 250 W |

Φ550×320 |

Electric + hand (0–180 mm) |

← Swipe Left and Right to View the Table→

Here the step up in rotary evaporator price reflects not only larger glassware and more powerful baths (up to 4 kW total) but also robust electric lifts and high-efficiency double condensers.

Is it better to buy a bigger rotary evaporator “just in case”?

Oversizing sounds safe but often leads to longer heat-up times, more difficult cleaning and higher running costs. A 20 L or 50 L system is ideal when there are regular multi‑liter batches; for typical R&D labs, a 2–5 L or 10 L model is usually more productive and economical day-to-day.

3. Typical Rotary Evaporator Price Ranges by Size

Exact rotary evaporator price depends on configuration, region, and accessories, but the following ranges describe the market pattern for quality laboratory equipment:

3.1 Small bench-top rotovaps (2–5 L)

Systems like the RE-201D (2 L) and RE-501 (5 L) are aimed at daily lab work. A complete set (rotovap, bath and basic glassware) from a reputable manufacturer typically falls into a “lower‑to‑mid” capital investment band compared with other lab equipment such as large freeze dryers or high-pressure reactors.

For context on how equipment pricing is explained on this site, the article on lyophilizer freeze dryer price details similar cost drivers (capacity, controls, materials). Rotary evaporator price follows a comparable logic.

3.2 Medium to pilot scale (10–50 L)

The RE-1002 / RE-2002 / RE-5002 series (10 L, 20 L, 50 L) and R1005–R1050 units are designed for kilo‑lab and small production:

-

Evaporation rate: from > 3 L/h (RE‑1002) up to > 9 L/h (RE‑5002)

-

Bath power: 3–9 kW depending on flask volume

-

Stronger frames, larger condensers and thicker glass

These are significantly more expensive than bench-top units, but when compared with the cost of pilot batches and solvent purchase, they are usually justified by the efficiency gains.

Based on data cited in a 2022 industrial sustainability report, solvent recovery steps can reduce overall operating costs of an extraction process by 20–40 % in mature plants.

10–50 L rotary evaporators are frequently used in pilot plants and cannabinoid or essential oil extraction lines.

3.3 How vacuum and chillers affect total project cost

When planning a realistic rotary evaporator budget, it is necessary to include:

-

Vacuum pump (water aspirator, diaphragm, or rotary vane)

-

Recirculating chiller for the condenser

-

Glassware spares and vacuum hoses

On small systems, these accessories may be similar in price to the rotovap itself; on large systems, they can be a smaller fraction of the total but still non‑negligible. Our guide on rotovap vacuum pumps discusses how pump choice influences both performance and lifetime cost.

4. Choosing the Right Size: Simple Capacity Rules

One of the most practical ways to approach rotary evaporator price is to start from the required throughput and work backwards.

4.1 Match flask size to typical batch volume

A useful rule for comfortable operation is to fill the evaporating flask only to about 30–50 % of its nominal volume to avoid bumping and to allow efficient film formation:

-

2 L rotovap → ideal for 0.5–1 L batches

-

5 L rotovap → 1.5–2.5 L batches

-

10 L rotovap → 3–5 L batches

-

20 L rotovap → 6–10 L batches

-

50 L rotovap → 15–25 L batches

Selecting a flask too small will require repeated runs; too large and much energy is wasted heating unused volume.

4.2 Consider solvent type and boiling point

High-boiling solvents (like some glycols) or viscous extracts need more heating power and sometimes an oil bath at higher temperature. In that case, it is better to choose a model with:

-

Higher bath power (e.g., 3000 W and above on 10–20 L models)

-

Stable temperature control over the 80–150 °C range

-

Reliable vacuum level to drop the boiling point

Is it necessary to buy a high-end electric lift model for a 5 L rotovap?

For a 2 L or 3 L unit, manual lift is usually fine. At 5 L, electric lift is convenient but not mandatory. Once 10 L and above are reached, electric or combined electric + manual lift greatly reduces operator fatigue and the risk of accidents, which justifies the higher rotary evaporator price in most professional settings.

Choosing between 2 L, 5 L, 10 L, 20 L and 50 L depends mainly on batch volume and workflow, not only on budget.

5. How to Evaluate Total Cost of Ownership

When comparing rotary evaporator price offers, it is helpful to think in terms of total cost of ownership (TCO) rather than only the initial quote.

5.1 Purchase price vs. operating cost

-

Energy consumption: A 4 kW bath running several hours a day adds up. However, faster evaporation can reduce total run time.

-

Solvent savings: Efficient recovery means buying less solvent and paying less for waste disposal.

-

Maintenance costs: Cheap seals and thin glass increase the risk of leaks or breakage. Quality PTFE and fluoro rubber seals, as used in the RE and R series, usually require fewer replacements.

5.2 Downtime and safety

Unexpected glass failures or unstable lifts cause downtime and safety issues. Investing slightly more upfront in a stable frame, good safety shields and reliable controls can prevent expensive interruptions.

5.3 Integration with other systems

In many labs, rotary evaporators work alongside freeze dryers, reactors and solvent recovery units. Resources on this site, such as the article “What is the rotovap method of extraction?” show how a rotovap can be integrated into a complete extraction and purification workflow.

Practical tip: When requesting quotations, it is useful to ask vendors to specify not only the rotary evaporator price, but also recommended vacuum pump, chiller capacity, spare glass package and estimated annual seal replacements. That gives a clearer picture of true annual cost.

6. Summary: Turning Rotary Evaporator Price into a Smart Investment

Rotary evaporators are not just another piece of lab glassware; they are workhorse systems that influence solvent consumption, product quality and operator safety every day. Understanding what lies behind rotary evaporator price makes it much easier to justify the right purchase.

-

Start from batch size and solvent type to choose flask volume and bath power.

-

Check vacuum performance and sealing materials for the solvents that are used most.

-

Decide whether electric lift and advanced controls will really be used in daily work.

-

Consider total cost of ownership: energy, solvent savings, maintenance and downtime.

With these points in mind, the headline rotary evaporator price becomes only one part of a much clearer economic picture. In many practical cases – especially where solvents are expensive or regulatory compliance is strict – a well-chosen rotovap pays for itself by improving efficiency and safety over its lifetime.

Note: All technical parameters referenced (flask volumes, bath power, evaporation rates and vacuum levels) are drawn from the manufacturer specifications of the RE series (2–50 L) and R series rotary evaporators. Actual market prices depend on configuration, region, certification requirements and accessories.

Products

Products