Description

Product Description

RE 501 rotary evaporator is electronically controlled to make the flask rotate at a constant speed at the most suitable speed to increase the evaporation area. The evaporating flask was kept under negative pressure by a vacuum pump. The evaporation flask is placed in a water bath for constant temperature heating while rotating, and the solution in the bottle is heated, diffused and evaporated in the rotating flask under negative pressure. The rotary evaporator system can be sealed and decompressed to 400-600 mm Hg; the solvent in the distillation bottle is heated with a heating bath, and the heating temperature can be close to the boiling point of the solvent; at the same time, it can also be rotated at a speed of 50-160 rpm. Make the solvent form a thin film and increase the evaporation area. In addition, under the action of the high-efficiency cooler, the hot vapor can be quickly liquefied and the evaporation rate can be accelerated.

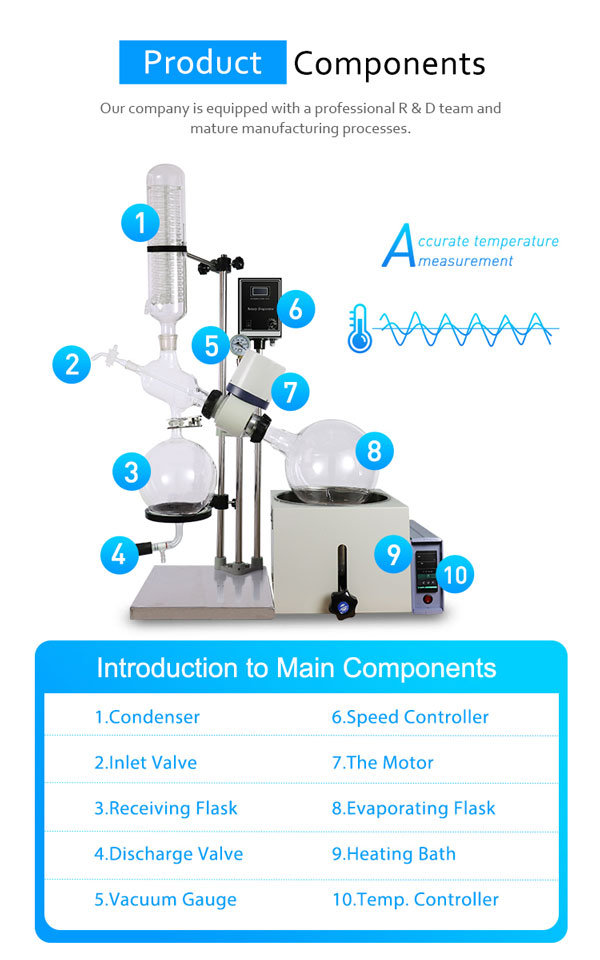

The main components of RE 501 rotary evaporator:

Condenser

Double serpentine condenser tubes are used, this structure can increase the heat exchange area and improve the condensation efficiency. The condenser is equipped with an external low-temperature circulating fluid pipeline interface and a pressure-reducing device interface, which can be connected to "low temperature source and temperature control device" or "vacuum acquisition and control device" as required to further improve condensation efficiency.

Receiving Flask

The receiving bottle is connected to the lower part of the condenser, and the condensed solvent is collected and temporarily stored in the bottle.

The Motor

Classified by function, the motor of re 501 rotary evaporator is divided into rotating motor and lifting motor. The rotating electrical machine is the main part of the rotating mechanism, and either an AC motor or a DC motor can be used. The user can control the steady-state speed of the rotary bottle by setting the speed through the "speed regulator" and "SET" key set on the operation panel; the lifting motor is the driving part of the rotary bottle lifting mechanism, and generally adopts a DC 24V motor.

Evaporating Flask

The rotary bottle is the core component for containing materials and performing rotary evaporation. Generally speaking, spinner bottles with a volume of 5L are used for small-scale experiments in the laboratory; spinner bottles with a volume of 5L and above are used for pilot tests or production.

Heating Bath

The water (oil) bath is the heating source of the rotary bottle, and the user can adjust the temperature of the bath liquid through the control system to change the evaporation rate of the material.

Product Advantages:

1. The main bracket is made of stainless steel + aluminum alloy, with reasonable structure and exquisite materials.

2. The vacuum pressure gauge shows the real-time vacuum degree.

3. All glass parts are made of high borosilicate glass (GG-17), high temperature resistance and corrosion resistance.

4. Continuous feeding is convenient for customers to use.

5. Vertical double-layer serpentine coil condenser to ensure high recovery rate, with additional material pipe.

6. The digital display of the heating bath, intelligent constant temperature control, and accurate transmission of temperature.

7. Advanced frequency conversion digital display speed regulation ensures electrical performance, digital display of speed, knob setting, and easy operation.

8. Fuses can be used for safety protection.

9. The inner pot is made of high-quality stainless steel, which is anti-corrosion and durable.

10. Equipped with high-efficiency double-tube condenser.

Applications

RE 501 rotary evaporator can rotate to form a thin film under constant temperature heating and negative pressure conditions, evaporate efficiently, and then cool and recover the solvent. It is especially suitable for operations such as crystallization, separation, and solvent recovery of heat-sensitive materials. Some models can also be used for reflux extraction. It is an important instrument and equipment for scientific research and production in the biological, pharmaceutical, chemical and food industries.

Installation Steps:

1. Preparations

Take the stainless steel bottom plate, vertical rod, bolts and nuts, vacuum gauge and gauge rod, and condenser fixing rod out of the packing box, and place them on the operating table stably.

2. Install the pole

Assemble the vacuum gauge and gauge rod, and the condenser fixing rod to the vertical rod;

Fix the assembled pole on the stainless steel base plate with bolts and nuts, and make the front of the vacuum gauge face the installer.

Once assembled, place the rack flat on the work bench.

3. Install the host

Install the host on the base of the machine head; tilt to the right about 45°C; lock the screws on the frame.

4. Install the glass shaft

Put the glass through-shaft into the host; install PTFE gaskets at both ends of the glass through-shaft.

5. Install the glass part

Fix the flange end of the four-way bottle on the machine head, connect the condenser to the four-way bottle, and make the joints of the condenser backward. Secure the condenser to the pole with the condenser retaining ring.

Connect the tetrafluoro tube to the feeding valve, and then install it to the left port of the four-way bottle

Dock the receiving bottle with the lower mouth of the four-way bottle, and clamp it with the bottle mouth clip;

Fix the bottle support ring on the pole with screws and adjust it to an appropriate height to stabilize the collection bottle;

Fix the rotating bottle to the right end of the rotating shaft with a flange;

Place the water bath under the spinner bottle, and add 2/3 of water or heat transfer oil to the pot.

6. Install the speed control box

Fix the speed control box on the pole, and plug in the five-pin plug of the motor. With the front of the governor box facing the installer.

Safety Instructions

1. Please keep a dry working environment. All electronic components cannot be immersed in water. Any damage to any components, sensors or switches caused by moisture/immersion will not constitute a warranty.

2. All gaskets must be cleaned and lubricated regularly (use 5-8 times or 72 hours), otherwise it will cause leakage and performance degradation.

3. When the rotary evaporator is working, the cooling water pipeline and the vacuum tube should be unimpeded, and there must be no bends in the pipeline.

4. It is strictly forbidden to use an electric furnace or an open flame to directly heat the rotary bottle, please use the matching water bath to provide safe heating.

5. The water bath must be filled with water first, then powered on, and then cut off the power after use. After the water bath is heated, do not touch it with your hands to avoid scalding.

6. The depth of adding water to the water bath should be at least 3~5cm below the pt100 thermocouple probe; pay attention to the water depth of the water bath, and add water in time to avoid dry boiling. (Dry boiling without water in the tank is strictly prohibited). Please cut off the power supply, let the heating tube cool down naturally, never add water when it is not completely cooled

Products

Products

Get Price

Get Price Send Email

Send Email