Spray drying is one of the most effective and widely used methods for converting liquid materials into dry powders. A spray dry machine is the core equipment behind this process, transforming liquids into fine particles through controlled heat and airflow. This technology is essential in industries ranging from food processing to pharmaceuticals and chemicals.

1. What Is a Spray Dry Machine?

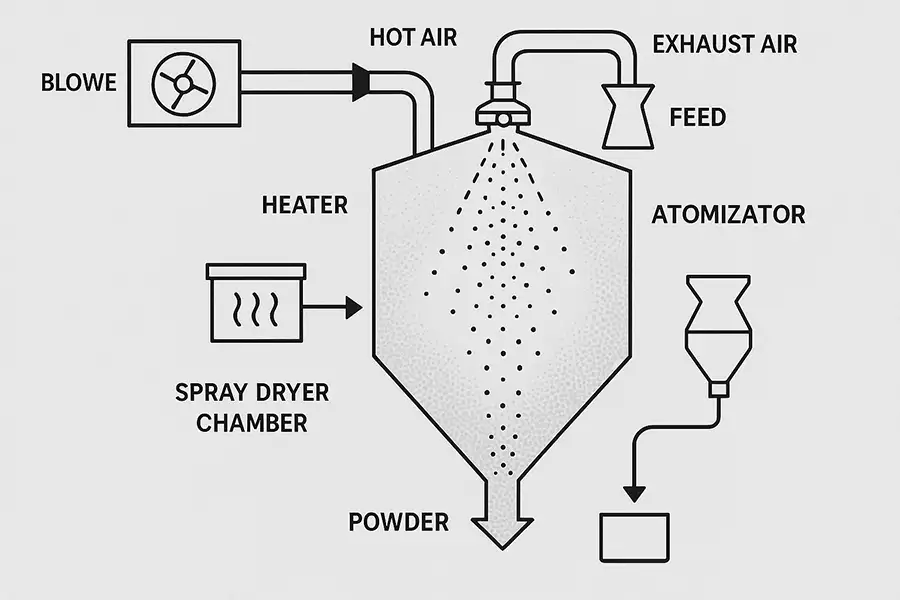

A spray dry machine is a device that atomizes a liquid feed into small droplets and exposes them to a stream of hot air. The moisture evaporates almost instantly, leaving behind fine, dry particles. This process allows for the production of powders with controlled particle size, moisture content, and flowability.

According to a study by the University of Cambridge, spray drying is capable of reducing liquid moisture content from over 90% to less than 5% within seconds, making it an extremely efficient dehydration method.

2. How Does a Spray Dry Machine Work?

The working principle of a spray dry machine involves three main stages: atomization, drying, and powder collection.

-

Atomization: The liquid feed is converted into fine droplets using a nozzle or rotary atomizer.

-

Drying: These droplets are exposed to hot air, causing rapid evaporation of moisture.

-

Collection: The dried powder is separated from the air and collected in a cyclone or bag filter system.

Wondering what factors influence the quality of the final powder?

Answer: The inlet air temperature, feed concentration, and atomization speed are key. Adjusting these parameters allows precise control over particle size and moisture content.

3. Applications of Spray Dry Machines

Spray drying is used across multiple sectors, each benefiting from its ability to produce stable and uniform powders:

|

Industry |

Application |

Example Product |

|

Food Processing |

Drying milk, coffee, fruit juices |

Instant coffee powder |

|

Pharmaceutical |

Producing powdered drugs and excipients |

Antibiotic powders |

|

Chemical |

Drying polymers and catalysts |

Silica powder |

For example, the comparison between spray dryers and dehydrators shows that spray dryers achieve more uniform particle formation and faster drying times.

4. Advantages of Using Spray Dry Machines

Spray drying offers numerous benefits:

-

Rapid drying with minimal thermal degradation.

-

Consistent particle size and shape.

-

Excellent control over powder properties.

-

Scalability for laboratory and industrial production.

According to research published by the International Journal of Food Engineering, spray drying can preserve up to 85% of heat-sensitive nutrients compared to traditional drying methods.

Is spray drying safe for food applications?

Answer: Yes, it is. As detailed in this article on spray drying food safety, the process operates under controlled conditions that maintain hygiene and product integrity.

5. Choosing the Right Spray Dry Machine

Selecting the right spray dry machine depends on several factors:

-

Feed type: Liquid viscosity and solids content determine the nozzle type.

-

Production scale: Laboratory spray dryers differ significantly from industrial ones.

-

Temperature sensitivity: Some materials require low-temperature drying to maintain quality.

For laboratory-scale setups, consider reading Lab Spray Dryer for Sale: A Comprehensive Guide for detailed specifications and performance insights.

6. Spray Drying Technology Innovations

Modern spray dry machines are equipped with advanced control systems, automated cleaning, and energy-efficient designs. Some models now integrate AI-based monitoring to optimize drying parameters in real time. According to a recent report by the European Chemical Engineering Society, automated spray dryers can reduce energy consumption by up to 25% compared to conventional models.

Another innovation is the use of closed-loop systems that recycle hot air, reducing environmental impact while maintaining high drying efficiency. This aligns with the global trend toward sustainable manufacturing.

7. Conclusion

Spray dry machines are indispensable in modern production environments. They offer precision, speed, and versatility, making them ideal for industries that demand high-quality powder products. Whether used for food, pharmaceuticals, or chemicals, spray drying ensures consistent results with minimal waste.

To explore more about spray drying technology and its applications, visit our in-depth guide on milk powder spray dryers for technical insights and operational tips.

In summary, investing in a reliable spray dry machine is not only a technological upgrade but a step toward improved efficiency and product quality. As industries continue to evolve, this equipment will remain at the forefront of innovation and productivity.

Products

Products