Description

Introduction To Paint Solvent Recycling Machine

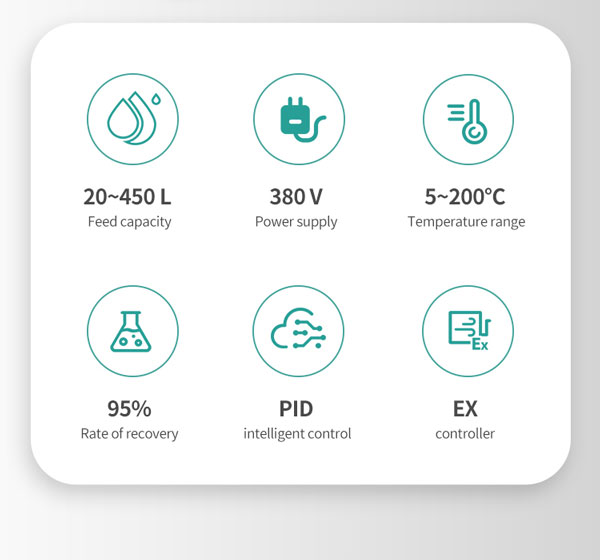

The paint solvent recycling machine recycles by indirect heating distillation. Firstly, the heat transfer oil is heated by the heater, and then the heat transfer oil transfers the temperature to the solvent in the recovery barrel, making it reach the boiling point to form mature gas, and the steam flows out through the cooling pipe through air cooling or water cooling to liquefy, and finally realizes solid-liquid separation.

Advantages Of Paint Solvent Recycling Machine

High recovery rate:

The recovery rate of waste toluene is as high as 95%.

Small footprint:

The toluene recovery machine is small in size and occupies a small area.

More energy efficient:

For example, there are 100 liters of equipment in the world, and the equipment of other companies is equipped with heat conduction injection cycle, carbon steel base, and a lot of heat conduction oil, etc., which causes the recovery time of 100 liters of equipment to be extended to 5 hours, and the power is 12KW. And our equipment, the power is only 6KW, and the working time is also 3-4 hours.

Operational security:

Because it adopts the indirect heating of heat transfer oil, the operation safety of the paint solvent recycling machine is greatly improved.

Chemical composition retained:

The paint solvent recycling machine can remove all impurities in the solvent because it adopts the principle of pure physical purification, so it does not change the chemical composition of the original solvent.

Application Of Paint Solvent Recycling Machine:

1. Ethers: chlorobenzene, etc.;

2. Halogenated chemicals: chlorobenzene, alcohol, dichloromethane, trichloroethylene, etc.; 3. Ketones: acetone, methyl ethyl ketone, methyl isobutyl ketone, etc.;

4. Fats: pentane, hexane, octane, etc.; 5. Alcohols: methanol, ethanol, isopropanol, etc.;

6. Aromatic agents: toluene, xylene, trimethylbenzene, etc.;

7. Esters: methyl acetate, ethyl acetate, n-butyl acetate, etc.;

8. Alicyclic classics: cyclohexane, cyclohexanone, tolyl cyclohexanone, etc.;

9. And other organic solvents not listed (solvents that evaporate quickly at room temperature can be recovered).

Safe Operation Specification:

Main sources of danger: electric shock injury, mechanical injury, fire hazard, etc.

Before work

1. Check whether the indoor forced ventilation system can work normally.

2. Whether the recycling bin and cover are in good condition and whether they are damaged.

3. Whether the motor power cord of the acetone recycling machine and the machine power cord are normal.

At work

1. When adding waste solvent, depending on the viscosity of the solvent, add an appropriate amount of waste liquid, and do not exceed the maximum liquid level line. At the same time, too little solvent should not be added to avoid dry burning in the final stage.

2. Pay attention to the sealing of the barrel and the tightness of the lid when closing the lid.

3. During the recycling process of acetone recovery machine equipment, its working status should be checked regularly.

4. After recycling, turn off the power.

5. After the machine returns to normal temperature, open the cover to clean up the waste residue.

6. Pay attention to careful operation during operation, and do not spill or splash solvent or residue around.

After work:

1. Clean up the site and turn off all power.

2. Make relevant records.

In an emergency:

Immediately press the emergency stop button of the acetone recovery machine to stop, and take correct measures to prevent the accident from expanding. If anyone is injured, rescue immediately; if there is a fire, call the police immediately, and at the same time put out the primary small fire. If it cannot be controlled, evacuate immediately according to the fire alarm plan, and report to the security officer and other leaders at the same time.

Operation Case

Toluene recovery:

1. Set the heating temperature for recovering toluene according to the boiling point of toluene. When setting the heating temperature, the value should be about 50 degrees higher than the actual boiling point of toluene. For example, if the boiling point of toluene is 110.6°C, the heating temperature can be set at about 160-165°C;

2. Set working time, high temperature alarm, shutdown temperature and other parameters according to the technical parameters of paint solvent recycling machine;

3. Put the waste toluene into the recovery barrel through manual or automatic feeding pump;

4. Use a rag to wipe the edge of the mouth of the recycling bin, and cover the lid;

5. Turn on the paint solvent recycling machine to start recycling;

6. After the recovery of toluene is completed, collect and store the recovered solvent, and when the temperature of the heated kerosene drops to about 50C, clean up the residue and foreign matter in the recovery barrel;

7. Add waste solvent for the next round of recovery.

FAQ

Q: What should I do if the waste solvent recovered by the paint solvent recycling machine cannot be evaporated?

A: There are usually three situations where the solvent cannot be evaporated to dryness:

(1) There is a lot of water in the waste solvent, which leads to the set working time of the equipment, and there is still a lot of waste liquid in the recovery bucket of the solvent recovery machine;

(2) When recovering the mixed solvent, the solvents with low boiling point have all been recovered, but there are still some solvents with high boiling point that are not recovered due to insufficient heating temperature;

(3) The recovery time set is too short, the recovery time can be extended appropriately.

Q: What should I do if there is steam leakage when the paint solvent recycling machine is in use?

A: When it is found that there is solvent vapor leakage when the paint solvent recycling machine is working, there may be the following problems:

(1) The cooling pipe is blocked: the steam cannot flow out after being cooled by the cooling management, and a certain pressure is generated in the recovery bucket, and the steam overflows from the lid of the recovery bucket under the pressure. The solution is the same as above.

(2) The sealing ring is not well sealed: the sealing ring of the barrel lid of the solvent recovery machine should be replaced in time every 3000 times.

Q: What should I do if the paint solvent recycling machine smokes?

A: (1) Since the paint solvent recycling machine often handles different solvents, if it is not cleaned frequently, a thick layer of residue will be stained in the bucket. If the residue in the recycling bucket is not cleaned thoroughly, the residue will accumulate thicker and thicker , In the state of high temperature heating, the residue will harden and carbonize, and the automatic shutdown time will be prolonged, causing the residue to overheat and smoke.

(2) The contact part between the gasket (sealing ring of the barrel lid) and the recovery barrel is not cleaned, causing the steam to flow out. If there is a heat source around the steam, it will also cause the solvent recovery machine to smoke.

Products

Products

Get Price

Get Price Send Email

Send Email