Description

Working temperature of hydrothermal synthesis reactor: ≤230 ° C, working pressure: ≤2MPa. With complete PTFE material lining and excellent acid and alkali resistance.

The pot body and the lid are sealed with a durable and reliable sealing structure, and the sealing effect can be stable for a long time without leaking.

Features:

- Working Temperature: ≤230°C

- Working Pressure: ≤2MPa (Pressure Gauge)

- Heating and Cooling Rate: ≤5°C/min

- Using high-quality 0Cr18Ni9Ti nonmagnetic stainless steel.

- The kettle body and the cover are sealed by a durable, reliable sealing structure, the sealing effect could be long-term stable without leakage.

- Complete PTFE material liner, with excellent acid resistance and alkali resistance.

Hydrothermal synthesis reactor can be used for:

Digestion of heavy metals, agricultural residues, food, sludge, rare piles of earth, aquatic products, organic matter, etc. Therefore, it is widely used in research and production in petrochemical, biomedical, material science, geochemical, environmental science, food science, and commodity inspection and other departments.

After sale:

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

FAQ

1. What should I pay attention to when using a hydrothermal synthesis reactor?

a. During use, the temperature is strictly not to exceed the maximum use temperature of 220 degrees Celsius, working pressure: ≤3Mpa (gauge pressure)

b. The amount of reaction solvent to be added depends on different experiments and is generally 60% -80% of the inner cup capacity. If the gas production of the reactants is large, cold nitration is recommended overnight. Pay special attention to the use of perchloric acid and hydrogen peroxide!

c. The quality of the oven should be good. The actual temperature control inside the oven should reach ± 2 degrees Celsius. It is necessary to consider that some old-fashioned ovens will have an overshoot of 20 degrees Celsius, which is more obvious at high temperatures.

d. When the oven starts to heat up, there must be no personnel in the room to prevent the explosion from hurting people! It can be entered only after the temperature is lowered to room temperature, and necessary safety protection measures, such as face protection, hand protection, respiratory protection, etc., are required when removing the can.

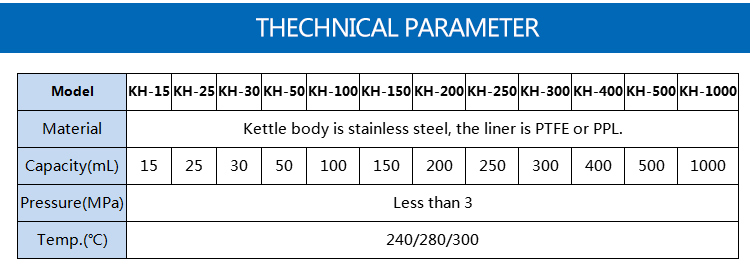

2. Main technical characteristics of hydrothermal synthesis reactor

a. Working temperature: ≤230 ° C

b. Working pressure: ≤2MPa (pressure gauge)

c. Heating and cooling rate: ≤5 ° C / min

d. Specifications: 25ml, 50ml, 100ml, 150ml, 200ml, 250ml. We can also provide customized sizes according to user needs.

3. What are the main materials for making a hydrothermal kettle?

a. Use high-quality 0Cr18Ni9Ti non-magnetic stainless steel.

b. The pot body and the lid are sealed with a durable and reliable sealing structure. The sealing effect can be stable for a long time without leaking.

c. Full PTFE material with excellent acid and alkali resistance.

Products

Products

Get Price

Get Price Send Email

Send Email