Description

100L Jacketed glass raector vessel benefits:

Frequency control motor

Stable operation

High vacuum diploma

Constant speed stirring

Precise temperature management

Efficient distillation

100L jacketed glass reactor details:

Constant pressure funnel

Feed rapidly,no residual,acid and alkali resistance,temp vary:-100℃-400℃.

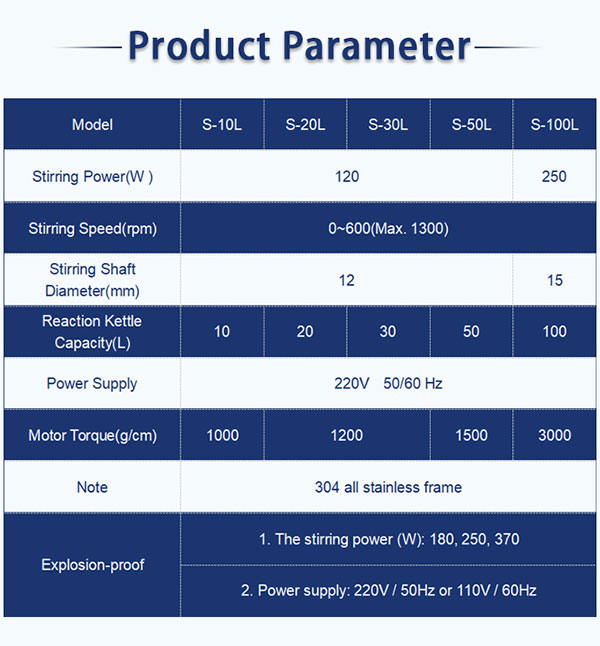

Gear motor

Smooth running,excessive torque,automated booster,no spark,explosion proof is optionally available.

Kettle cowl

It is convenient to clean,disassemble,and set up PT100 temperature probe.

Double layer glass kettle physique

High quality borosilicate 3.3 glassware.

FAQ

A Borosilicate 100L jacketed glass reactor provides a distinctive benefit of response visibility, which is unimaginable in other construction supplies. A glass reactor is suitable for main reactions in API and chemical business. The full set of glass parts is produced by GG-17 high borosilicate glass, owns wonderful chemical and physical properties. Our merchandise are used in prescription drugs, scientific analysis, chemical crops, universities, and other chemical and organic laboratories, merchandise offered in a hundred countries and territories worldwide, products get customers to praise.

100L jacketed glass reactor vessel condenser to improve materials restoration and tools efficiency. To shield the instrument from injury when steam passes via the jacketed glass reactor, the vapor pressure usually ... Glass Triple walled Reactor or Glass Triple jacketed Reactor is specially designed for Cryogenic Reaction for small batches.

Our 100L glass reactor vessel is a compact system with interchangeable vessels and is suitable for placing in a fume hood. Various vessel options and equipment let you choose exactly what you want for your process. Basic process Along with the rapid growth of recent business, particularly the chemical trade, there are many ki... The heating media circulate can be controlled and monitored with the assistance of vales placed on the inlet. The totally different sizes can be chosen depending on the process’s requirement, the batch size, and the solvent requirements in the batch.

Our major products include rotary evaporator, the double glass reactor vessel, cryogenic coolant circulation pump, vacuum pump. In chemical engineering, a jacketed container is a container designed to manage the temperature of its contents by utilizing a cooling or heating "jacket" around the container, via which cooling or heating fluid circulates. A jacketed glass reactor is essentially a reactor where a glass jacket has replaced the standard heating oil bathtub. Jacketed Glass Reactor is designed to react and blend several sorts of materials underneath specific adjustable temperature and vacuum circumstances. Wiped film molecular distillation is a special liquid-liquid separation technology, which is totally different from traditional distillation on the difference boiling level.

This provides a quick and efficient thermal change between the process and thermal source. 10L jacketed glass reactors has good chemical properties and can be utilized between -80°C and 200°C. When utilizing this technology in your course of, you will want to have not only the best size vessel , but in addition the right filtration media. This component is crucial to the successful filtration of your product.

Products

Products

Get Price

Get Price Send Email

Send Email