Spray drying is one of the most efficient and widely used methods for transforming liquid materials into dry powders. It plays a crucial role in industries ranging from food production to pharmaceuticals and chemicals. But what exactly is the spray drying process, and why is it so effective?

Understanding the Basic Principle

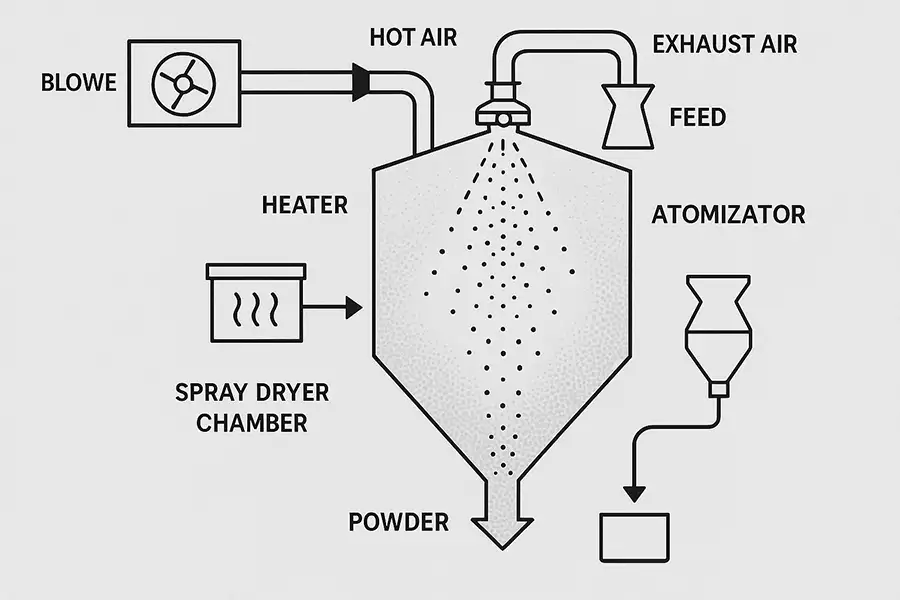

At its core, spray drying involves atomizing a liquid feed into a hot drying chamber. The liquid—usually a solution, slurry, or suspension—is converted into tiny droplets using an atomizer. These droplets are then exposed to a stream of hot air, which evaporates the moisture almost instantly. The result is a fine, uniform powder collected at the bottom of the chamber.

According to research by the University of Cambridge, spray drying can reduce moisture content to less than 5% in under 10 seconds, making it one of the fastest drying technologies available.

What makes spray drying different from other drying methods like freeze drying or air drying?

Spray drying operates at high temperatures and involves rapid evaporation, whereas freeze drying uses low temperatures and vacuum conditions to sublimate moisture. Air drying, on the other hand, relies on slower evaporation. Spray drying offers a balance of speed and control, making it ideal for heat-sensitive materials when optimized properly.

Step-by-Step Breakdown of the Process

-

Preparation of Feed: The liquid feed is prepared by dissolving or suspending the material in a suitable solvent.

-

Atomization: The feed is sprayed into a chamber through a nozzle or rotary atomizer, creating fine droplets.

-

Drying: Hot air (typically between 150°C to 300°C) rapidly removes moisture from the droplets.

-

Separation: The dried particles are separated from the air using cyclones or filters.

-

Collection: The final powder is collected and packaged for use.

Applications Across Industries

Spray drying is used in diverse industries:

-

Food industry: Production of milk powder, coffee, flavorings, and protein supplements.

-

Pharmaceuticals: Creating stable formulations of drugs and probiotics.

-

Chemicals: Drying of catalysts, polymers, and detergents.

For instance, in milk powder production, spray dryers ensure uniform particle size and instant solubility. You can learn more about this in our detailed guide Guide to Milk Powder Spray Dryers.

Is spray drying safe for food and pharmaceutical applications?

Yes, when conducted under controlled conditions, spray drying is safe and widely approved. As discussed in

Is Spray Drying Food Safe?, the process maintains product integrity and minimizes contamination risks through closed-system designs.

Advantages of Spray Drying

Some of the main advantages include:

-

Rapid drying and high throughput.

-

Excellent control over particle size and moisture content.

-

Scalability from laboratory to industrial production.

-

Ability to handle heat-sensitive materials with proper temperature control.

Modern spray drying equipment, such as the spray dryer machine, integrates automation and temperature monitoring to ensure consistency and efficiency.

Challenges and Optimization

While spray drying is highly efficient, it requires precise control of parameters such as air temperature, droplet size, and feed concentration. Improper settings can lead to uneven drying or product degradation. Advanced machines now include real-time feedback systems and AI-based optimization, which, according to a study by the Technical University of Munich, can improve yield by up to 25%.

Comparing Spray Drying with Other Technologies

Spray drying is often compared with freeze drying and vacuum drying. Each method has its strengths, but spray drying stands out for its cost-effectiveness and speed. For laboratory-scale operations, a compact laboratory spray dryer offers flexibility and precision for research and small batch production.

How can one choose the right spray drying machine for specific applications?

The choice depends on factors like feed properties, desired particle size, and production scale. Industrial models are suitable for bulk production, while lab-scale units are ideal for testing formulations. Consulting with equipment specialists ensures the right configuration for optimal results.

Conclusion

Spray drying is a transformative process that bridges science and industry. It converts liquids into powders efficiently, preserving product quality and extending shelf life. From milk powder and pharmaceuticals to chemical catalysts, the technology continues to evolve with innovations in automation and sustainability.

For more insights into drying technologies and comparisons, explore related articles on ZZKD Instrument’s Spray Dryer Guide.

Products

Products