Struggling to find the most efficient cannabinoid extraction method? You want high yields and purity. This challenge can impact your product quality and bottom line significantly.

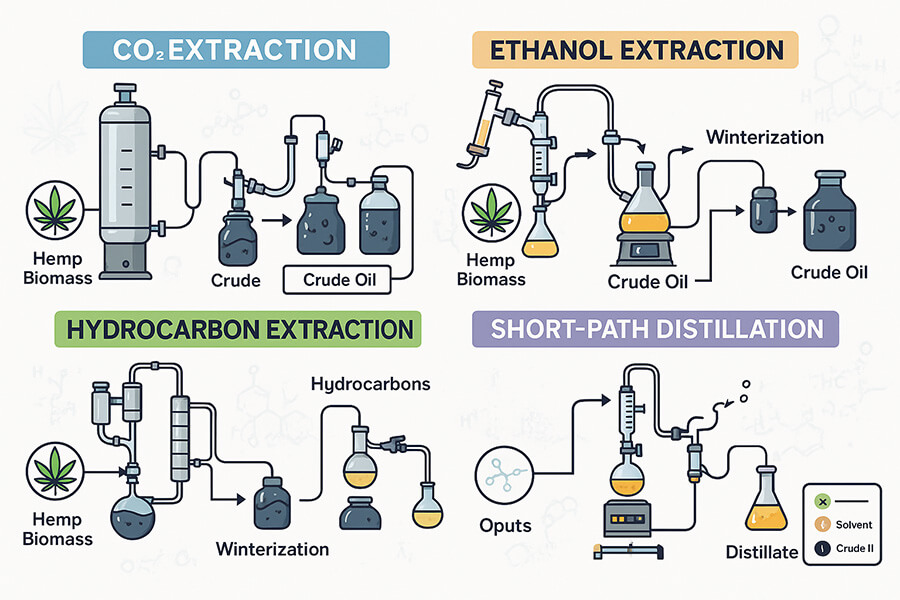

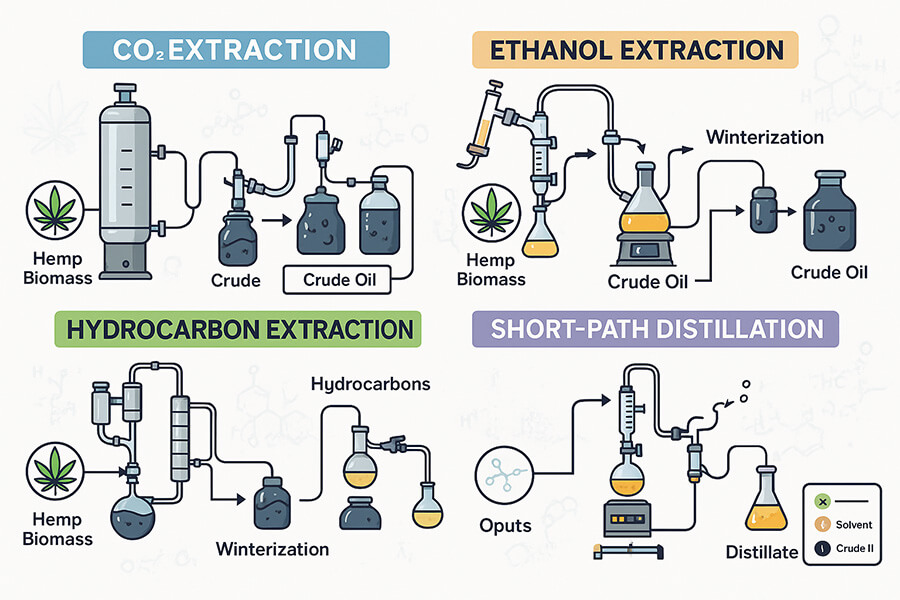

The "best" way depends on your specific goals, scale, and budget. Common methods include ethanol, CO2, and hydrocarbon extraction, each with unique benefits for producing high-quality cannabinoid products.

Choosing the right extraction method is a big decision for any business in the cannabis and hemp industry. As a manufacturer with over 16 years of experience in exporting laboratory and production equipment, I've seen how this choice shapes success. We've helped countless clients worldwide, from startups to large-scale processors in 87 countries, navigate this. Let's explore what makes an extraction method suitable for you.

What exactly is cannabinoid extraction and why is it so important for quality products?

You hear about cannabinoids like CBD and THC everywhere. But how do they get from the plant into products? This is where extraction, a critical first step, comes in.

Cannabinoid extraction is the process of isolating desired compounds like CBD or THC from the cannabis or hemp plant material. It's vital for creating concentrated, pure, and safe end products.

Understanding extraction is key. Think of it like making coffee. The coffee beans are the plant material, and the hot water is the solvent. The goal is to get the caffeine and flavor (cannabinoids and terpenes) out of the beans and into the water, leaving the grounds behind. In our industry, this process is much more precise. We need to separate specific valuable compounds from hundreds present in the plant.

Why Precision Matters in Extraction

The quality of your final product—be it an oil, tincture, or isolate—starts with good extraction. Poor extraction can lead to:

-

Low yields: Not getting enough of the valuable cannabinoids.

-

Impurities: Carrying over unwanted plant matter like chlorophyll or waxes.

-

Residual solvents: If not properly purged, solvents can remain in the product.

As an ISO9001 and CE certified manufacturer, we at Zhengzhou Keda (ZZKD) stress the importance of controlled, efficient extraction. It’s not just about getting cannabinoids out; it’s about getting them out cleanly and efficiently. This ensures the safety and efficacy of the final products, which is what your customers demand and deserve. This is why we focus on providing equipment that offers precise control over temperature, pressure, and solvent recovery.

Which primary methods are used for extracting cannabinoids from hemp and cannabis?

Confused by all the different extraction methods? It's a common issue. Each has its place, and knowing the main types is the first step to choosing wisely.

The primary methods for cannabinoid extraction are solvent-based (using ethanol, hydrocarbons like butane/propane, or CO2) and solventless methods (like rosin pressing or ice water extraction).

Let's break these down a bit. For over 16 years, we've manufactured equipment for various methods, so I can share some insights.

Solvent-Based Extraction: The Workhorses

These methods use a liquid solvent to dissolve the cannabinoids and terpenes from the plant material.

-

Ethanol: Known for its safety (GRAS - Generally Recognized As Safe) and efficiency at various temperatures.

-

Hydrocarbons (Butane, Propane): Excellent at preserving terpenes, leading to flavorful extracts. Requires careful handling due to flammability.

-

CO2 (Supercritical or Subcritical): Highly tunable, allowing for selective extraction. CO2 is also safe and evaporates completely.

Each solvent interacts differently with the plant. For example, cold ethanol is great for leaving unwanted fats and chlorophyll behind. Our

rotary evaporators and

falling film evaporators are essential for recovering these solvents efficiently after extraction, which is crucial for cost-effectiveness and purity.

Solventless Extraction: The Artisanal Approach

These methods use mechanical force or temperature changes, not liquid solvents.

-

Rosin Pressing: Uses heat and pressure to squeeze out resin.

-

Ice Water Extraction (Bubble Hash): Uses ice water and agitation to separate trichomes.

While often simpler in terms of equipment, scaling solventless methods for large commercial production can be challenging compared to solvent-based ones. However, they are prized for their purity and "natural" appeal.

How does ethanol extraction work for cannabinoids and what are its pros and cons?

Considering ethanol for your extraction? It's a popular choice, but understanding its workings, advantages, and disadvantages is important before you commit your resources.

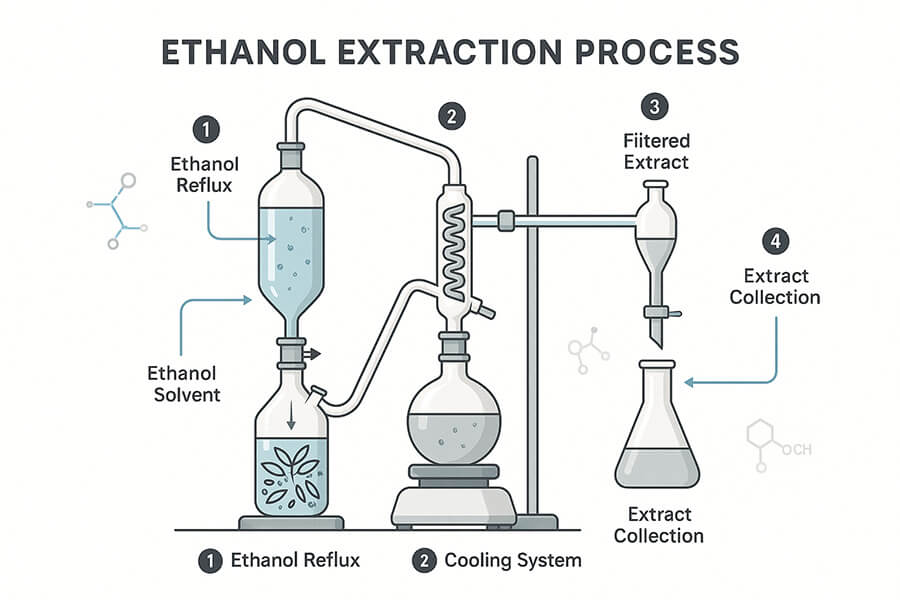

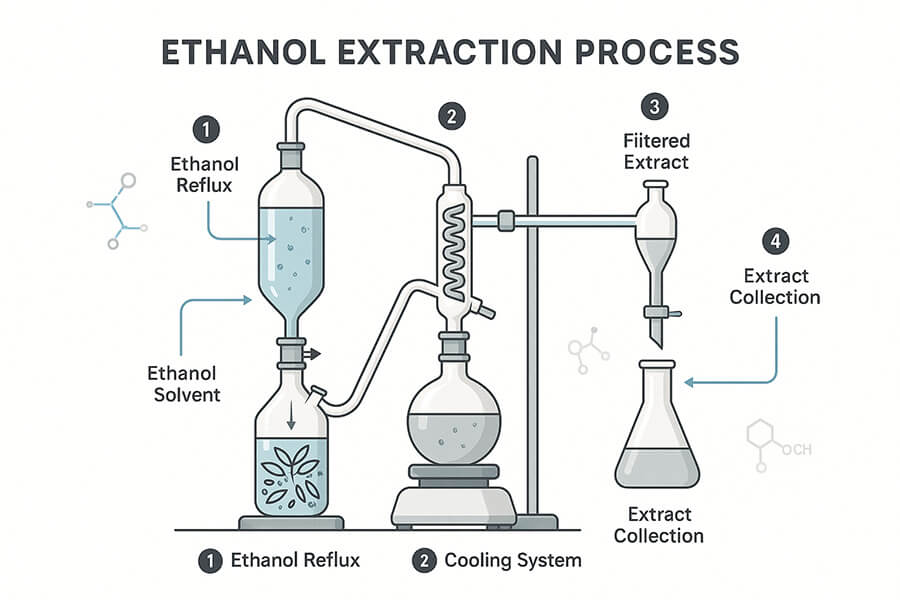

Ethanol extraction involves soaking cannabis material in chilled or room-temperature ethanol to dissolve cannabinoids and terpenes. It's scalable and efficient but may pull some undesirable compounds like chlorophyll.

Ethanol is a powerful solvent. We've seen many clients, especially those scaling up, choose ethanol due to its effectiveness and relative safety. The basic steps are:

-

Chilling: Often, both the ethanol and the plant material are chilled to very low temperatures (e.g., -40°C). This helps prevent the extraction of waxes and chlorophyll. Our chillers play a vital role here.

-

Extraction: The plant material is soaked or washed with the chilled ethanol.

-

Filtration: The mixture is filtered to remove plant solids. We provide robust filter reactors for this stage.

-

Solvent Recovery: This is where the ethanol is evaporated from the extract to concentrate the cannabinoids. This is a critical step where our rotary evaporators and falling film evaporators shine, allowing for high recovery rates.

Pros and Cons of Ethanol Extraction

|

Pros |

Cons |

|

Generally Recognized As Safe (GRAS) by the FDA. |

Can co-extract chlorophyll and waxes if not done cold, requiring further refinement. |

|

Highly efficient at extracting a broad spectrum of cannabinoids. |

Ethanol is polar, so it readily binds with water-soluble compounds. |

|

Scalable for both small and large operations. |

Solvent recovery requires energy and efficient equipment. |

|

Ethanol can be reclaimed and reused, reducing operational costs. |

Lower selectivity compared to CO2 without specific temperature control. |

← Swipe Left and Right to View the Table→

In my experience, the key to successful ethanol extraction lies in temperature control and efficient solvent recovery. Investing in good quality chillers and evaporation systems makes a huge difference. That's what we focus on at ZZKD – providing "Made in China + International Quality" equipment that you can rely on.

What makes CO2 extraction a popular choice for cannabinoids, and is it always better?

Heard about CO2 extraction and its "clean" reputation? It's a sophisticated method, but is it the ultimate solution for every cannabinoid processor out there?

CO2 extraction uses carbon dioxide in its supercritical or subcritical state as a solvent. It's valued for its tunability, safety (non-flammable, non-toxic), and ability to produce pure extracts with no residual solvent.

CO2 extraction is quite fascinating. By changing the temperature and pressure, you can change the state of CO2 and its solvent properties. This "tunability" is a major advantage.

Understanding Supercritical and Subcritical CO2

-

Supercritical CO2: At higher temperatures and pressures, CO2 acts like a gas but has the density of a liquid. It's a strong solvent, good for full-spectrum extraction.

-

Subcritical CO2: At lower temperatures and pressures, CO2 is less dense and acts as a gentler solvent, better for preserving delicate terpenes but less efficient for cannabinoids.

The process involves pumping CO2 through the plant material in an extractor vessel. The CO2 dissolves the cannabinoids and terpenes, and then it's separated from the extract in another vessel by changing pressure, allowing the CO2 to return to a gaseous state and be recycled. This means virtually no solvent residue if done correctly.

Is CO2 Always the Best?

While CO2 extraction offers significant benefits, it's not a universal "best."

|

Advantages of CO2 Extraction |

Considerations |

|

Highly tunable for selective compound extraction. |

High initial equipment cost compared to ethanol systems. |

|

CO2 is non-toxic, non-flammable, and readily available. |

Can be slower than some hydrocarbon methods. |

|

Leaves no residual solvent in the final product. |

Supercritical CO2 can co-extract waxes, requiring winterization. |

|

Environmentally friendly due to CO2 recycling. |

Requires skilled operators due to high pressures involved. |

← Swipe Left and Right to View the Table→

As manufacturers, we don't produce CO2 extractors themselves, but we supply essential ancillary equipment like chillers for precise temperature control, which is critical in CO2 systems, and post-processing equipment like short-path distillation units for further refinement of CO2 extracts. The choice often comes down to your production goals, desired end-product, and capital investment capacity.

Are solventless cannabinoid extraction methods a good alternative for my operation?

Looking for a "natural" approach to cannabinoid extraction? Solventless methods avoid chemical solvents, but are they practical and efficient for your business goals?

Solventless extraction methods like rosin pressing or ice water hash use mechanical action, temperature, or water to separate cannabinoids. They offer purity but can be less scalable for very large volumes.

Solventless methods are gaining popularity, especially in markets that value artisanal and "chemical-free" products. I've seen a growing interest in these techniques among our customers.

Common Solventless Techniques:

-

Rosin Pressing: This involves applying heat and immense pressure to cannabis flower, kief, or hash. The heat melts the resin, and the pressure squeezes it out. The result is a pure, solvent-free extract called rosin. It’s simple in principle but requires a good quality press for consistency.

-

Ice Water Extraction (Bubble Hash): Plant material is agitated in ice-cold water. The cold temperature makes the cannabinoid-rich trichomes brittle, and they break off. These trichomes are then filtered through a series of micron bags, resulting in bubble hash. This hash can be sold as is or further processed (e.g., pressed into rosin).

-

Dry Sifting (Kief): This involves agitating dried cannabis flower over a series of screens to collect the trichomes (kief). It's a simple mechanical separation.

The main appeal of solventless is the absence of any foreign substances, which can be a strong selling point. However, scalability can be a concern. While you can get high-quality products, the throughput for large-scale commercial operations might not match solvent-based systems unless you invest in multiple units or very large automated systems, which are emerging. Yields can also sometimes be lower compared to efficient solvent extraction. For us, while we don't directly make rosin presses, our freeze dryers are often used by producers to perfectly dry their bubble hash before pressing, ensuring top quality.

What crucial post-extraction steps refine cannabinoids for the final product?

Think extraction is the final step? The crude oil often needs more work. Post-extraction refinement is key to achieving the purity and form your customers expect.

Crucial post-extraction steps include winterization (dewaxing), decarboxylation, distillation, and isolation to purify cannabinoids and create specific product formulations. These steps are vital for quality.

After the initial extraction, the resulting crude oil often contains cannabinoids, terpenes, but also fats, waxes, lipids, and chlorophyll, depending on the method. Here’s how we, at ZZKD, help refine it with our specialized equipment:

Key Refinement Processes:

-

Winterization (Dewaxing): Crude extract (especially from ethanol or warmer CO2 extraction) is mixed with ethanol and then chilled to very low temperatures using our chillers. This causes fats and waxes to solidify. The mixture is then filtered using our filter reactors or other filtration setups to remove these unwanted components, resulting in a cleaner oil.

-

Solvent Recovery (Again!): If ethanol was used for winterization, it needs to be removed. Our rotary evaporators or falling film evaporators are perfect for this, ensuring maximum solvent recovery for reuse.

-

Decarboxylation: Raw cannabinoids are often in their acidic form (e.g., CBDA, THCA). Decarboxylation is the process of heating them to convert them into their active forms (CBD, THC). This can be done in a reactor or specialized decarboxylation reactors, offering precise temperature control.

-

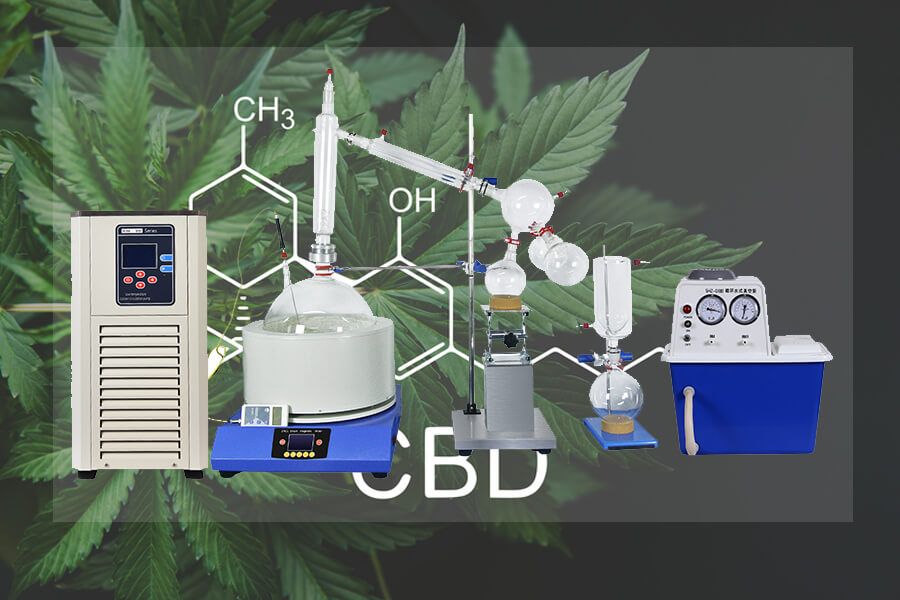

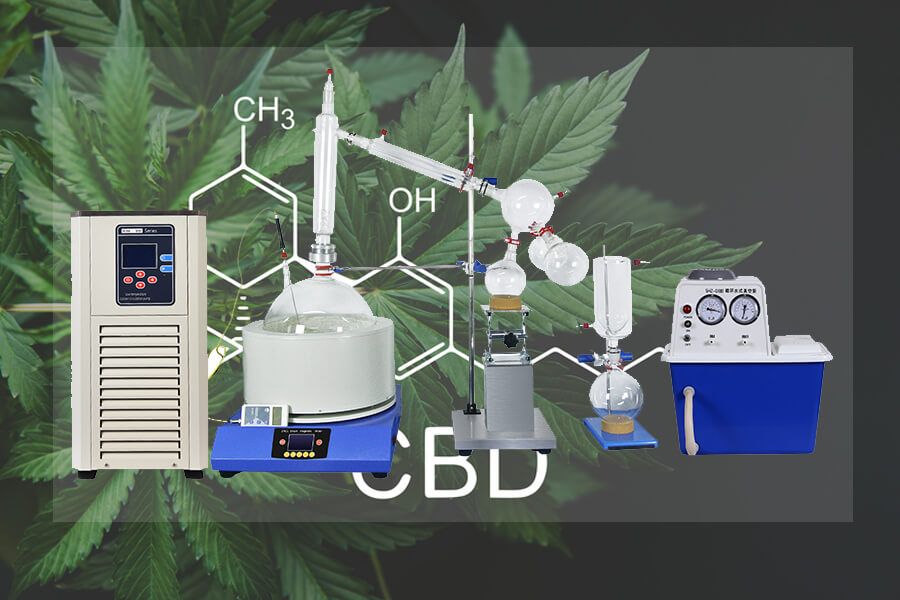

Distillation: This step further purifies and separates cannabinoids based on their boiling points. Our short-path distillation and wiped film distillation systems are widely used to produce high-purity distillate, often achieving over 90% cannabinoid potency. This is where you get that beautiful golden, clear oil.

-

Isolation (Crystallization): To produce nearly 100% pure cannabinoids (e.g., CBD isolate), further processing involving crystallization techniques is used. This often involves dissolving distillate in a solvent, then inducing crystallization through temperature changes, followed by filtration and drying. Our reactors and vacuum ovens (a type of drying equipment) can be part of this process.

Each of these steps requires precise control and reliable equipment. With our 16 years of production and export experience, and our ISO9001 and CE certifications, we ensure our equipment meets international quality standards for these demanding applications.

How can I choose the ideal cannabinoid extraction equipment for my specific business needs?

Feeling overwhelmed by choices? Selecting the right equipment is a big investment. You need a setup that matches your scale, product goals, and budget for long-term success.

Choose equipment by considering your target products, production volume, budget, regulatory requirements, and desired level of automation. Consulting with experienced manufacturers is also key.

As a company that has specialized in laboratory and production equipment for over 16 years, we always tell our clients to start with their end product in mind.

Factors to Guide Your Decision:

-

End Product: Are you making full-spectrum oil, distillate, isolate, or terpene-rich extracts? This heavily influences the type of extraction and post-processing equipment needed. For instance, for high-purity distillate, our short-path distillation units are essential.

-

Scale of Operation: A startup might begin with smaller batch equipment like our benchtop rotary evaporators and glass reactors, while a large-scale facility will need industrial-sized falling film evaporators and stainless steel reactors.

-

Budget: CO2 systems have high upfront costs. Ethanol systems can be more moderate initially but require robust solvent recovery systems. Factor in operational costs too. We aim to provide high value-for-money products.

-

Regulations: Understand local laws regarding solvents, facility safety (explosion-proofing for hydrocarbons), and product purity. Our equipment often comes with CE certification, and we can discuss specific needs.

-

Expertise: Some systems require more technical expertise to operate safely and efficiently. Consider your team's skills. We offer 24/7 after-sales support, and over 50% of our engineers are fluent in English to assist you.

-

Future Growth: Think about modularity or systems that can be scaled up.

My advice is always to talk to people who have experience. We've exported to 87 countries and participated in 15 international exhibitions. We encourage technical exchange and factory visits. We want to understand your needs to recommend the right solution, whether it's a complete extraction line or specific pieces of equipment like vacuum pumps or chillers that support your existing setup. Our goal is "Worry-Free Global After-Sales" to ensure your operations run smoothly.

Choosing the best cannabinoid extraction method involves matching technology to your goals. Consider scale, product, and budget for optimal results and high-quality, pure cannabinoid products.

Products

Products