From morning milk powder to cutting-edge pharmaceuticals, spray drying silently shapes our daily lives. Discover how this rapid-fire technique turns liquids into stable, free-flowing powders in seconds.

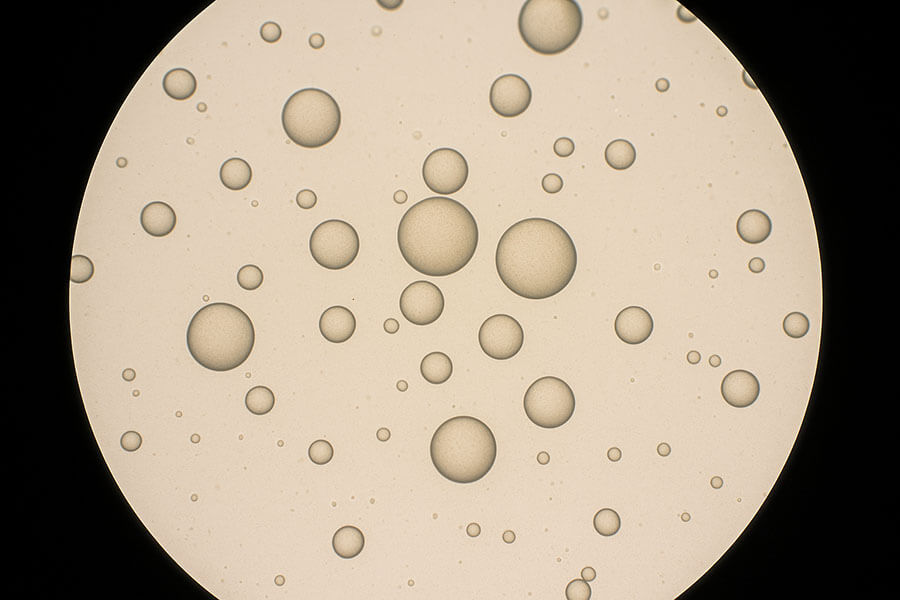

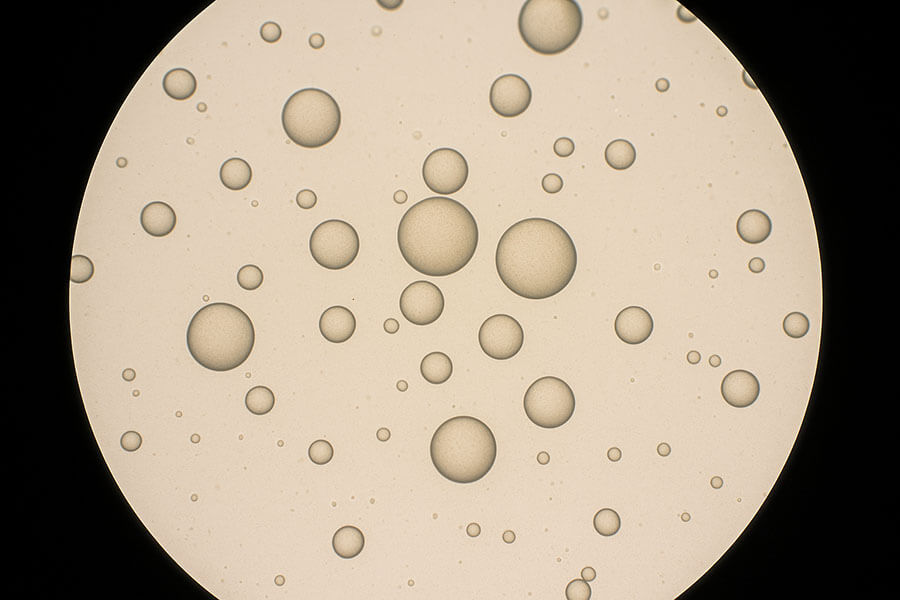

Spray drying is a continuous and scalable process that converts a pumpable liquid – be it a solution, dispersion or emulsion – into a dry powder by atomising it into a hot drying gas. The resulting particles can range from less than one micron to several hundred microns and, most importantly, retain critical functional properties such as flavour, bio-activity or solubility.

Because of its versatility, the technology has migrated far beyond its first application (milk in 1872) and now underpins innovative products across food, pharma, biotech and advanced materials. According to a report by Markets & Markets, the global spray-drying equipment market is projected to reach USD 7.2 billion by 2027, growing at 6.8 % CAGR – clear evidence that industries keep finding new uses for the method.

Why Do Engineers & Formulators Love Spray Drying?

Speed

Liquid to powder in milliseconds means minimal thermal exposure and high throughput.

Control

Particle size, bulk density and moisture can be tuned by tweaking feed rate, temperature and nozzle type.

Stability

Removing water locks in flavour, potency or reactivity, extending shelf life dramatically.

Question: Does spray drying always mean “high heat” that could destroy sensitive ingredients?

Answer: Not necessarily. Because droplet diameters are so small, even an inlet air temperature of 180 °C can translate to product temperatures below 60 °C. Coupled with protective carriers (e.g., maltodextrin or whey proteins), vitamins, probiotics and even live vaccines can survive the journey.

Five Everyday Examples of Spray Drying in Action

1. Milk & Dairy Powders

The quintessential application. Whole and skimmed milk, infant formula and even cheese powders rely on spray dryers for instant solubility and safe storage. Large single-stage towers can dry more than 30 tons of milk solids per hour. Curious about performance differences between spray dryers and classic drum dryers? Our comparison digs into the numbers.

2. Coffee & Tea Extracts

Instant coffee granules are generated by spray drying concentrated coffee liquor, sometimes followed by an agglomeration step to improve wetting. Aroma recovery systems capture volatile flavours that would otherwise be lost, reincorporating them before final packaging.

3. Pharmaceuticals & Nutraceuticals

From amorphous solid dispersions that boost bio-availability of poorly soluble drugs to micro-encapsulated fish oil softgels, pharma scientists use spray dryers to engineer precise particle morphologies. For a deep dive into food-safety aspects, see our article “Is Spray Drying Food Safe?”.

4. Flavours & Fragrances

Volatile oils are entrapped in a carrier matrix, yielding free-flowing powders that dissolve on impact with hot water or melt in the mouth. Spray-dried vanilla, garlic or citrus oils drastically reduce shipping costs compared with liquid counterparts.

5. Battery & Ceramic Materials

In the energy-storage sector, lithium iron phosphate (LFP) cathode powders are often produced via spray drying of precursor slurries, ensuring uniform particle chemistry before calcination. Similarly, advanced ceramics such as zirconia benefit from homogeneous spray-dried granules that pack densely in moulds.

Question: How does spray drying compare with freeze drying in energy consumption?

Answer: Freeze drying may require up to 6 – 10 kWh per kg of water removed, largely due to deep vacuum and long cycle times. A modern spray dryer typically uses 1 – 2 kWh per kg of water, making it the go-to choice for high-volume, heat-tolerant products.

|

Industry |

Typical Feed |

Key Benefit of Spray Drying |

|

Food & Beverage |

Milk, coffee extract, flavours |

Instant solubility, extended shelf life |

|

Pharmaceutical |

API solutions, probiotics |

Controlled particle size, gentle drying |

|

Biotechnology |

Enzymes, vaccines |

Scalable sterile processing |

|

Energy Materials |

Battery slurry, fuel cell inks |

Uniform chemistry across particles |

|

Cosmetics |

Hyaluronic acid, plant extracts |

Easy incorporation into powders & masks |

← Swipe Left and Right to View the Table→

“According to research from the Massachusetts Institute of Technology, AI is expected to automate 30 % of current job tasks by 2030.” – MIT Work of the Future Report

The increasing automation predicted for the next decade perfectly aligns with the trend toward fully automated spray-drying lines equipped with AI-driven self-optimising controls.

Question: Is lab-scale spray drying relevant for start-ups?

Answer: Absolutely. Benchtop units processing just 50 mL – 5 L/h enable rapid prototyping with grams of material, slashing R&D timelines. When a formula works, scale-up to industrial towers is straightforward because the underlying heat and mass-transfer principles remain the same. For a detailed buyer’s guide explore our milk-powder spray dryer article.

Ready to Transform Liquids into Powders?

Whether the goal is to craft an award-winning instant latte, stabilise a sensitive probiotic or manufacture next-generation battery cathodes, a properly specified spray dryer is the heart of the process.

Compare Spray Dryer Models

Products

Products