Struggling with inefficient drying methods for your liquid products? Heat damage or inconsistent results a constant worry? We understand these challenges.

Spray drying instantly transforms liquid feed into dry powder by atomizing it into a hot gas stream. This rapid, gentle process preserves product quality, making it ideal for sensitive materials.

You might be surprised by how this technology works and the benefits it can bring to your operations. As a manufacturer with over 16 years of experience in exporting equipment like spray dryers, we've seen firsthand its transformative power. It was just last year when a client in the pharmaceutical sector approached us, desperate to find a way to dry a highly sensitive new drug formulation without losing its efficacy. Traditional methods were failing them. We introduced them to one of our custom spray dryers, and the results were game-changing for their research. Let's explore this fascinating process further.

How Exactly Does a Spray Dryer Magically Turn Liquids into Fine Powders?

Curious about the science behind instant powder creation? Does transforming liquids into dry particles in seconds seem like complex magic? Let’s demystify it.

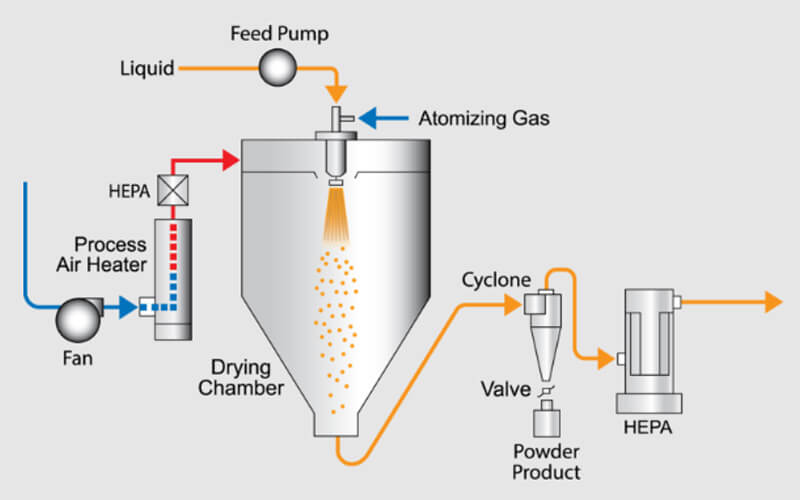

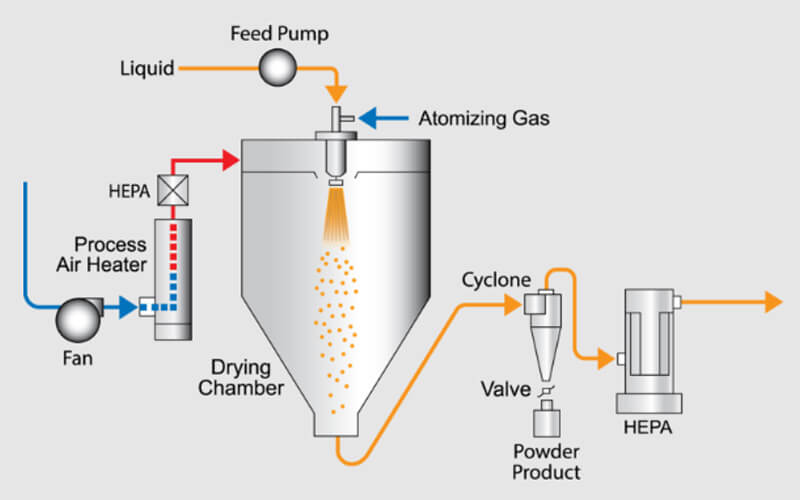

A spray dryer works by atomizing a liquid feed into fine droplets within a hot drying gas. The high surface area allows for rapid evaporation, leaving behind dry powder particles.

A spray dryer machine is a sophisticated piece of equipment, but its core working principle is elegantly simple. It involves three fundamental stages that we meticulously control in our ZZKD machines:

1. Atomization: Creating the Mist

This is where the magic begins. The liquid feed – your solution, suspension, or emulsion – is dispersed into a spray of very fine droplets. Think of it like a perfume atomizer, but on an industrial scale, designed for continuous, reliable operation. There are several ways we achieve this in our equipment, depending on your product's characteristics:

-

Rotary Atomizers: These use a high-speed spinning disc to fling the liquid outwards, breaking it into droplets. They are great for a range of feed materials and can handle higher viscosities.

-

Nozzle Atomizers: These force the liquid through a small orifice at high pressure. We have different types, like pressure nozzles for simple solutions and two-fluid nozzles where compressed air helps break up more viscous or complex liquids. I remember working with a food ingredient company that needed to produce very fine, consistent powder from a tricky emulsion; a specialized two-fluid nozzle was key to their success.

The goal here is to create a vast surface area. More surface area means faster, more efficient drying. The choice of atomizer is something our engineers spend a lot of time discussing with clients to ensure optimal performance.

2. Drying (Liquid-Gas Contact): The Evaporation Step

Once we have these tiny droplets, they are introduced into a stream of hot gas, usually air (though we can design systems for nitrogen if your product is oxygen-sensitive). This is where the actual drying happens. The heat from the gas provides the energy needed for the solvent (usually water) in the droplets to evaporate. The contact between the droplets and the hot gas must be carefully controlled. We design our drying chambers to ensure:

-

Efficient mixing: Droplets and hot gas need to interact effectively for uniform drying.

-

Controlled temperature profile: The temperature must be high enough for quick evaporation but not so high that it damages your product. For example, when we helped a client in the food industry dry heat-sensitive milk proteins, we precisely calibrated the inlet and outlet temperatures, sometimes even using multi-stage drying.

3. Powder Separation and Collection: Gathering Your Product

As the solvent evaporates, you're left with dry solid particles. These particles then need to be separated from the drying gas. This is typically done using:

-

Cyclones: These use centrifugal force to separate the heavier powder particles from the lighter gas stream. They are highly efficient for most particle sizes.

-

Bag Filters or Wet Scrubbers: Sometimes, for very fine particles or when there are very strict emission controls (common in pharmaceutical or specialty chemical applications), we might incorporate these secondary collection systems.

The collected powder is then discharged from the dryer. I remember a pharmaceutical client who needed exceptionally high purity for their product; we designed a closed-loop system with multiple collection points, using a series of cyclones and a final bag filter, to ensure minimal product loss and absolutely no contamination. This entire process, from liquid to powder, can occur in a matter of seconds. It's this speed and efficiency that makes spray drying so valuable across so many applications.

Why is Spray Drying the Preferred Choice for So Many Different Industries?

Are your current drying methods too slow or damaging your valuable products? Looking for a versatile solution that delivers consistent quality and high throughput?

Spray drying offers rapid, gentle drying, suitable for heat-sensitive materials. It produces consistent particle sizes and is highly versatile, making it ideal for pharmaceuticals, food, chemicals, and more.

The popularity of spray drying isn't accidental; it stems from a unique set of advantages that make it incredibly versatile. As an exporter dealing with clients from 87 countries through ZZKD, we've seen its adoption in countless fields. Here's why it's so widely embraced:

1. Unmatched Speed and Efficiency

The transformation from liquid to dry powder happens in seconds. This rapid drying time significantly increases throughput compared to methods like oven drying or even freeze-drying for many bulk applications. For instance, a dairy company we worked with was able to process thousands of liters of milk into high-quality milk powder per hour using one of our industrial spray dryers. This scale was simply unthinkable for them with their previous batch drying methods, allowing them to expand their market reach significantly.

2. Ideal for Heat-Sensitive Materials

Although hot gas is used, the actual exposure time of the product to high temperatures is very short. More importantly, the "evaporative cooling" effect plays a crucial role: as the solvent evaporates from the droplet surface, it cools the particle. This inherent protection makes spray drying perfect for:

-

Pharmaceuticals: Preserving the activity of sensitive Active Pharmaceutical Ingredients (APIs) and biologics.

-

Food Products: Maintaining flavors, colors, vitamins, and nutritional value in items like instant coffee, milk powder, infant formula, and fruit juice powders. We once helped a startup develop a novel fruit powder that retained almost 100% of its vitamin C content, thanks to precise temperature control in our spray dryer.

-

Biotechnology: Drying enzymes, proteins, or microorganisms like probiotics without denaturation, which is critical for their functionality.

3. Superior Control Over Particle Characteristics

Spray drying allows for excellent control over the final powder properties, which is a huge advantage. By adjusting atomization parameters, feed rate, and drying conditions, we can help you engineer particles with specific attributes:

-

Particle Size and Distribution: Whether you need very fine powder for inhalation drugs or larger, agglomerated particles for better rehydration in food products.

-

Bulk Density: This influences flowability, packaging volume, and dispersibility.

-

Moisture Content: Achieving precise residual moisture levels for product stability.

-

Particle Morphology: Typically, spray drying produces spherical particles, which often have better flow properties and less dustiness compared to irregularly shaped particles from other drying methods. A client in the ceramics industry needed very specific, dense spherical particles for their advanced materials, and we customized a spray dryer with a specialized nozzle and airflow design to meet their exact requirements.

4. Scalability and Continuous Operation

Spray dryers are designed for continuous operation, making them ideal for large-scale industrial production. This reduces downtime and improves overall process efficiency. Furthermore, the technology is highly scalable, from our lab-scale ZZKD models perfect for R&D (handling milliliters of feed) to massive industrial plants processing tons of product per hour. This scalability allows companies to develop a product in the lab and then seamlessly scale up production using the same core technology.

5. Versatility in Feed Material

It can handle a wide variety of feed types, including solutions, suspensions, emulsions, and even some pastes (with appropriate pre-treatment and pump selection). This flexibility makes it applicable to a vast range of products without needing entirely different drying setups.

Here's a quick table showing some industries and common applications, highlighting the key benefits sought:

|

Industry |

Common Applications |

Key Benefit Sought with Our ZZKD Equipment |

|

Food & Beverage |

Milk powder, coffee, tea extracts, fruit juices, flavors, spices, food colorants, infant formula |

Speed, quality retention (flavor, nutrients), particle properties (solubility) |

|

Pharmaceutical |

APIs, excipients, drug delivery systems (e.g., microcapsules), vaccines, inhalable drugs, taste masking |

Gentle drying, particle size control for bioavailability, purity, aseptic capabilities |

|

Chemical |

Catalysts, pigments, detergents, polymers, ceramics, inorganic salts, agrochemicals |

Particle engineering (size, morphology, density), speed, continuous operation |

|

Biotechnology |

Enzymes, proteins, peptides, microorganisms (probiotics, starter cultures), algae extracts |

Preservation of biological activity, gentle drying conditions, stable powder form |

|

Environmental |

Flue gas desulfurization (drying of sorbents), waste stream concentration |

Efficiency, volume reduction, conversion to manageable solids |

|

Cosmetics |

Herbal extracts, active ingredients for skincare, pigments |

Stability of active compounds, particle characteristics for formulation |

← Swipe Left and Right to View the Table→

This adaptability is a core reason why, after 16 years in this business, we at ZZKD continue to see growing demand for spray dryers across new and established sectors worldwide.

What Key Factors Should You Consider When Choosing the Right Spray Dryer?

Thinking of investing in a spray dryer but unsure where to start? Overwhelmed by the options and technical specifications? We can guide you.

Key factors include feed properties (viscosity, solids content), desired powder characteristics (particle size, moisture), capacity needs, heat sensitivity, and safety (solvent type, explosivity).

Selecting the right spray dryer is a crucial decision that can significantly impact your production efficiency, product quality, and operational costs. As a manufacturer specializing in laboratory and industrial equipment for over 16 years, we at ZZKD always advise our clients to consider several key factors. It's not just about buying a machine; it's about finding the perfect solution for your specific needs. Here’s what you should think about, and how we can help:

1. Understanding Your Feed Material

The characteristics of your liquid feed are paramount:

-

Nature of the Feed: Is it a true solution, a suspension with fine particles, an emulsion, or a more viscous paste? This directly affects the type of atomizer and feed pump we would recommend. For example, a fragile emulsion might require a gentle atomization technique.

-

Viscosity: Higher viscosity liquids can be more challenging to pump and atomize effectively. We might need to consider special pumps or even dilution if possible.

-

Solids Content: This influences the yield and the amount of energy required for drying. Higher solids content is generally more economical but can affect atomization.

-

Corrosiveness/Abrasiveness: The materials of construction for the dryer (e.g., various grades of stainless steel like 304, 316L, or even Hastelloy) will depend on how corrosive your feed is. Abrasive feeds can cause wear on atomizers and pumps, so hardened materials might be necessary. We once had a client working with a highly acidic chemical solution, so we specified a special corrosion-resistant alloy and non-metallic contact parts for their custom spray dryer.

-

Temperature Sensitivity of the Feed: Some feeds might degrade if held at elevated temperatures even before atomization.

2. Defining Your Desired Final Powder

What should your end product look like and how should it behave?

-

Particle Size and Distribution (PSD): Do you need a very fine powder (e.g., for inhalation drugs) or larger, free-flowing granules (e.g., for instant soups)? This is a critical output that dictates atomizer choice and operating parameters.

-

Bulk Density: This is important for packaging, storage, and handling.

-

Residual Moisture Content: How dry does the powder need to be for stability and flowability? We aim for precise control here.

-

Morphology: Are spherical particles desired for better flowability or specific applications? Spray drying tends to produce these.

-

Thermal Stability of the Powder: Can the dried powder withstand certain temperatures without degradation or caking?

-

Reconstitution Properties: If it's a food or pharma product, how well does it dissolve or disperse back into a liquid?

3. Production Capacity and Operational Scale

-

Evaporation Rate: How much solvent (usually water) needs to be removed per hour (e.g., kg/hr of water evaporation)? This is a primary sizing parameter for the dryer.

-

Feed Rate: How much liquid product do you intend to process per hour or per day?

-

Operating Hours: Will it be run in campaigns, or continuously 24/7?

-

Laboratory, Pilot, or Industrial Scale: Our ZZKD range includes small lab units for R&D (like our popular KD-SD015 lab spray dryer), versatile pilot plants for process development and small-scale production, and large industrial systems for full-scale manufacturing. We recently helped a university chemistry department set up a compact lab spray dryer for their polymer research, while simultaneously commissioning a multi-ton-per-hour unit for a major food ingredient manufacturer.

4. Product Heat Sensitivity

As discussed, spray drying is gentle, but the maximum allowable product temperature during the brief drying phase is a critical design input. This influences the choice of inlet and outlet drying gas temperatures and the overall design of the drying chamber.

5. Solvent Type (If Not Water)

If you are drying products from organic solvents rather than water, safety and environmental considerations become paramount. This may require:

-

Inert Gas Operation (Closed-Loop System): Using nitrogen instead of air to create an inert atmosphere, preventing any risk of explosion if the solvent vapors are flammable.

-

Solvent Recovery Systems: To efficiently reclaim valuable solvents (reducing operational costs) and to meet stringent environmental regulations on VOC emissions. We offer specialized solvent recovery machines that integrate seamlessly with our spray dryers. We've designed many such systems for clients in the pharmaceutical and specialty chemical industries.

6. Regulatory and Safety Requirements

-

GMP (Good Manufacturing Practices): Essential for pharmaceutical and many food applications. This influences design (e.g., crevice-free surfaces, specific materials of construction, clean-in-place (CIP) systems), and documentation. All our equipment comes with ISO9001 and CE certification, which is a good foundation, and we can build to meet further GMP requirements.

-

ATEX (Atmosphères Explosibles) / Explosion Safety: If dealing with flammable powders or solvents, explosion protection measures (e.g., explosion venting, suppression systems, intrinsically safe components) are legally required and crucial for safety. We have experience in designing ATEX-compliant systems.

7. Site Considerations and Budget

-

Space Availability: Physical footprint of the equipment, including height.

-

Utilities: Availability and cost of electricity, steam (if used as a heating source), compressed air, cooling water.

-

Overall Project Budget: This includes not just the spray dryer itself, but also ancillary equipment, installation, commissioning, and training. We always aim to provide high value-for-money solutions.

Making the right choice involves a careful evaluation of these factors. Our experienced team at ZZKD, with over 50% English-speaking engineers, is always ready to engage in a detailed discussion about your specific application. We can help you navigate these considerations and configure the ideal spray drying solution to meet your goals efficiently and cost-effectively. This collaborative approach is something I've always emphasized in my 16 years in this field.

How Can We at ZZKD Partner with You for Your Spray Drying Success?

Need more than just a machine? Looking for a reliable partner with deep expertise and robust support for your spray drying projects? We are here.

With 16+ years of export experience, ISO/CE certifications, and 24/7 after-sales support, ZZKD offers customized, high-value spray dryers and comprehensive service for global clients.

Choosing a spray dryer supplier is about more than just the equipment; it's about forging a partnership that ensures your success long after the installation. At Zhengzhou Keda Machinery and Instrument Equipment Co., Ltd. (ZZKD), we've built our reputation over 16 years as China's first laboratory instrument equipment manufacturer to independently export overseas. We achieve this by focusing on being that reliable, long-term partner for our clients in 87 countries. Here’s how we specifically support your spray drying needs and why customers choose us:

1. Deep Experience and True Customization

We are not just resellers; we are an integrated company specializing in R&D, production, selling, teaching, and chemical/biological pharmaceutical equipment. This comprehensive involvement means we understand the intricacies of spray drying technology from the ground up. Our core strength, especially in extraction, reactor, and drying equipment like spray dryers, lies in providing customized, high-cost-performance solutions. We don't believe in a one-size-fits-all approach. We listen intently to your specific requirements – whether for delicate R&D work, pilot-scale trials, or full industrial production – and our engineers tailor the spray dryer design accordingly. I recall a biotech startup that approached us with a unique challenge: drying a very fragile enzyme solution that was crucial for their new diagnostic kit. Standard spray dryer settings were denaturing the enzyme. Our R&D team collaborated closely with them, modifying nozzle design and airflow patterns, and ultimately delivered a bespoke lab-scale unit that perfectly preserved the enzyme's activity. This kind of tailored solution is what we strive for.

2. Unwavering Commitment to Quality and International Standards

Our motto, "Made in China + International Quality," is more than just a phrase; it's a promise backed by tangible credentials like ISO9001 and CE certifications. These ensure our equipment meets stringent global standards for safety, performance, and reliability. We leverage over 16 years of technical expertise to build robust machines designed for longevity and consistent operation. We know our equipment often forms a critical part of our customers' production lines, and quality is non-negotiable.

3. Comprehensive Product Ecosystem

While spray dryers are a key offering, our expertise extends to a wide range of related laboratory and production equipment. This is a significant advantage because spray drying rarely happens in isolation. We can provide:

-

Essential Ancillaries: Such as high-performance chillers for cooling, reliable vacuum pumps, and efficient solvent recovery systems designed to integrate seamlessly with your spray dryer setup.

-

Upstream Equipment: Like glass reactors or stainless steel reactors for preparing your liquid feed.

-

Downstream Equipment: Systems for powder handling, mixing, or packaging if needed.

This integrated approach means we can often offer you a more holistic, streamlined, and optimized solution from a single, trusted source.

4. Industry-Leading Global After-Sales Support

We were pioneers in this area, becoming the first manufacturer in China in our sector to establish a 24/7 after-sales support team. We understand that equipment uptime is critical to your operations. Our global hotline, staffed by knowledgeable technicians (over 50% of our engineers are fluent in English), ensures prompt response times to minimize any potential disruption. We stand by our products with a one-year free maintenance warranty and offer lifetime cost-price service for parts and labor beyond that. This commitment to "Worry-Free Global After-Sales" is a cornerstone of our customer relationships. One of our clients in Southeast Asia, running a large food processing plant, once called us late on a Friday with an urgent operational query. Our on-call engineer was able to troubleshoot the issue with them remotely within an hour, preventing a costly production halt over the weekend. That's the kind of support we aim to deliver.

5. Global Footprint and Transparent Collaboration

Having exported to 87 countries and consistently participated in 15 international exhibitions across 7 countries, we have a strong global brand influence and a keen understanding of diverse market needs and regulatory landscapes. We believe in transparency and building long-term trust. We always welcome technical exchanges and encourage factory visits to our facility in Zhengzhou. Seeing our R&D labs, production department (set up in 2015), and our expanded 1,600 square meter industrial park facility (since 2018) often gives clients great confidence in our capabilities.

Our goal at ZZKD is to be more than just an equipment supplier. We aim to be your dedicated partner in achieving efficient, high-quality powder production through spray drying. From initial consultation and innovative custom design to meticulous installation, comprehensive training, and steadfast long-term support, ZZKD is committed to your success. That’s why tens of thousands of enterprises and individuals globally have chosen us and given us their unanimous praise.

Conclusion

Spray drying offers incredible speed and versatility for diverse industries. With the right customized equipment and a supportive partner like ZZKD, you can efficiently transform liquids into high-quality powders, unlocking new product possibilities and operational efficiencies.

Products

Products