Love fresh fruit but hate how quickly it spoils? Wasting food and money is frustrating. Freeze-drying at home or in your facility is the perfect solution for long-lasting fruit!

Making freeze-dried fruit is simple: prepare your fruit, then use a freeze dryer to remove its water content by freezing it and then turning the ice directly into vapor under vacuum. This preserves taste, nutrients, and extends shelf life significantly.

As a company with over 16 years of experience in manufacturing laboratory and production equipment, including advanced freeze dryers, we've seen firsthand how this technology transforms perishable goods. It's not just about preservation; it's about unlocking new possibilities for food enjoyment, research, and product development. I remember when we first helped a small fruit farm preserve their excess harvest; their joy at saving their produce was immense. This guide will walk you through the process, making it easy to understand and achieve great results, whether you're a home enthusiast or a professional lab.

What Exactly is Freeze-Drying and How Does It Work for Fruit?

Heard of freeze-drying but not sure what it means? It might sound like complex science. But it is a straightforward process that keeps fruit nearly perfect for a long time.

Freeze-drying, also known as lyophilization, is a process where water is removed from fruit by first freezing it. Then, the frozen water is turned directly into vapor (sublimation) under a vacuum. This preserves the fruit's structure, flavor, and nutritional value remarkably well.

Let's explore this a bit more. The magic of freeze-drying lies in sublimation. This is where a solid (ice) turns directly into a gas (water vapor) without passing through a liquid phase. This gentle process is why freeze-dried fruit maintains its shape, color, and most importantly, its nutrients so well. We, as manufacturers of freeze dryers for over 16 years, focus on perfecting this in our equipment.

The Three Main Stages of Freeze-Drying:

-

Freezing Stage: First, the fruit is frozen solid. This needs to be done correctly, often to temperatures between -20°C and -50°C (-4°F and -58°F). The way it freezes affects the ice crystal size, which influences the drying quality. Our advanced freeze dryers offer precise temperature control for optimal freezing.

-

Primary Drying (Sublimation): Next, the frozen fruit is placed in a vacuum chamber. The pressure is lowered significantly, and a small amount of heat is applied. This causes the ice in the fruit to sublimate, turning directly into vapor. This vapor is then collected on a condenser within the freeze dryer. This stage removes about 95% of the water.

-

Secondary Drying (Desorption): Finally, a bit more heat is applied, and the vacuum might be increased further. This removes any remaining water molecules that are bound to the fruit's matrix. The goal is to get the moisture content down to about 1-4%.

This whole process, while sounding technical, is fully automated in modern freeze dryers like the ones we export globally. The result is a lightweight, shelf-stable product that rehydrates beautifully or can be enjoyed as a crunchy snack. We've designed our machines to handle these stages efficiently, ensuring consistent, high-quality results for our customers in 87 countries.

Which Fruits Work Best for Freeze-Drying and How Should You Prepare Them?

Want to try freeze-drying but unsure which fruits to start with? Worried about prepping them wrong? It's easier than you think; many fruits work great with simple preparation.

Most fruits can be freeze-dried successfully! Berries (strawberries, blueberries, raspberries), apples, bananas, peaches, and mangoes are excellent choices. Proper preparation involves washing, slicing or dicing uniformly, and sometimes pre-treating to prevent browning.

Choosing the right fruit and preparing it well is key to fantastic freeze-dried results. We've helped thousands of clients, from research institutions to food processors, select and prepare fruits for their specific needs using our equipment. Here are some more detailed tips:

Top Fruits for Freeze-Drying:

-

Berries (Strawberries, Blueberries, Raspberries): Wash gently. Strawberries should be sliced or halved. Blueberries can be left whole but may benefit from being lightly scored to help moisture escape.

-

Apples and Pears: Peel (optional), core, and slice or dice. A light dip in an ascorbic acid solution (vitamin C) or lemon juice diluted in water can prevent browning.

-

Bananas: Peel and slice. They also benefit from an anti-browning dip.

-

Peaches and Nectarines: Peel (blanching can help), pit, and slice.

-

Mangoes and Pineapples: Peel, core/pit, and cut into slices or chunks.

-

Citrus Fruits (Oranges, Lemons): Can be freeze-dried, usually in segments or slices, often with the peel on for zest.

General Preparation Tips:

|

Preparation Step |

Why It's Important |

Our Tip |

|

Wash Thoroughly |

Removes dirt and pesticides. |

Use cool running water. Pat dry gently. |

|

Uniform Slicing/Dicing |

Ensures even drying. Pieces about 1/4 to 1/2 inch thick are ideal. |

A mandoline can be helpful for consistent slices. |

|

Pre-treatment (for some fruits) |

Prevents enzymatic browning in fruits like apples and bananas. |

A brief dip in a solution of 1/4 tsp ascorbic acid powder per cup of water works well. |

|

Single Layer on Trays |

Allows for better air/vapor circulation and even drying. |

Don't overcrowd the freeze dryer trays. We design our tray systems for optimal loading. |

← Swipe Left and Right to View the Table→

I remember a customer who was new to freeze-drying and was having trouble with apple slices. We discussed their preparation, and a simple switch to thinner, more uniform slices, along with pre-treatment, made all the difference. The quality of our freeze dryers ensures that once prepared correctly, the fruit will dry perfectly.

What Are the Key Steps to Freeze-Dry Fruit Using a Modern Freeze Dryer?

Got your fruit ready but the freeze dryer seems complex? Worried about messing up a batch? With modern machines, it's mostly automated and very user-friendly.

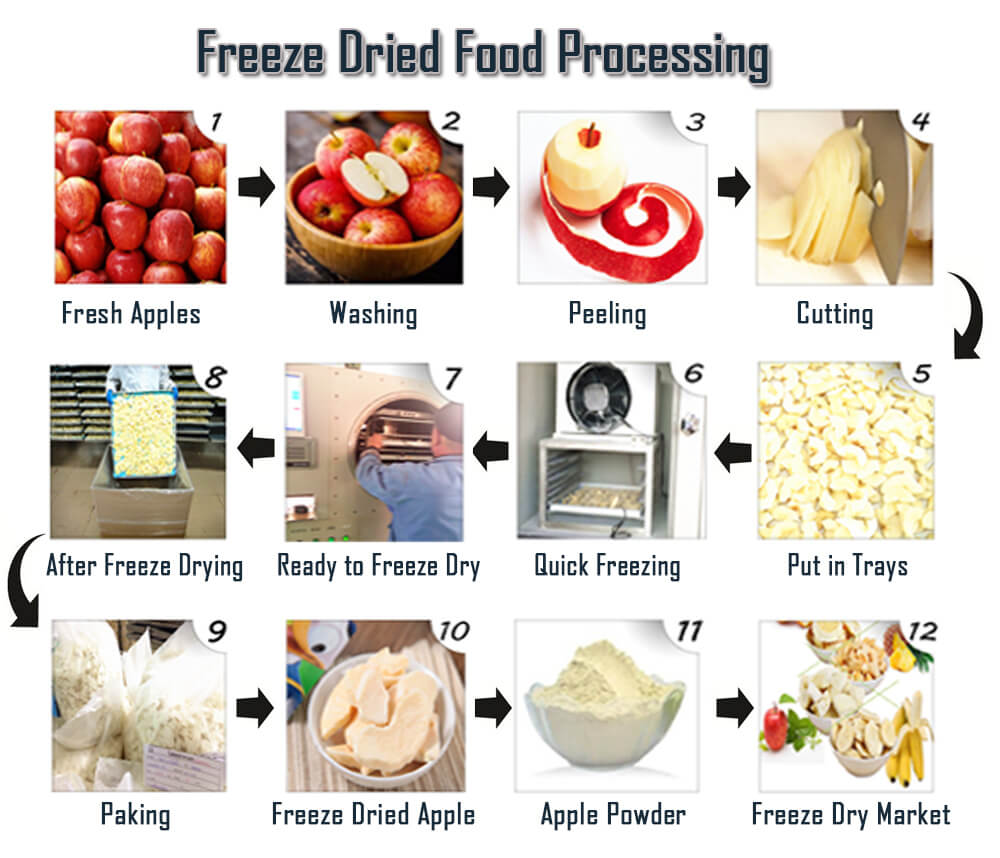

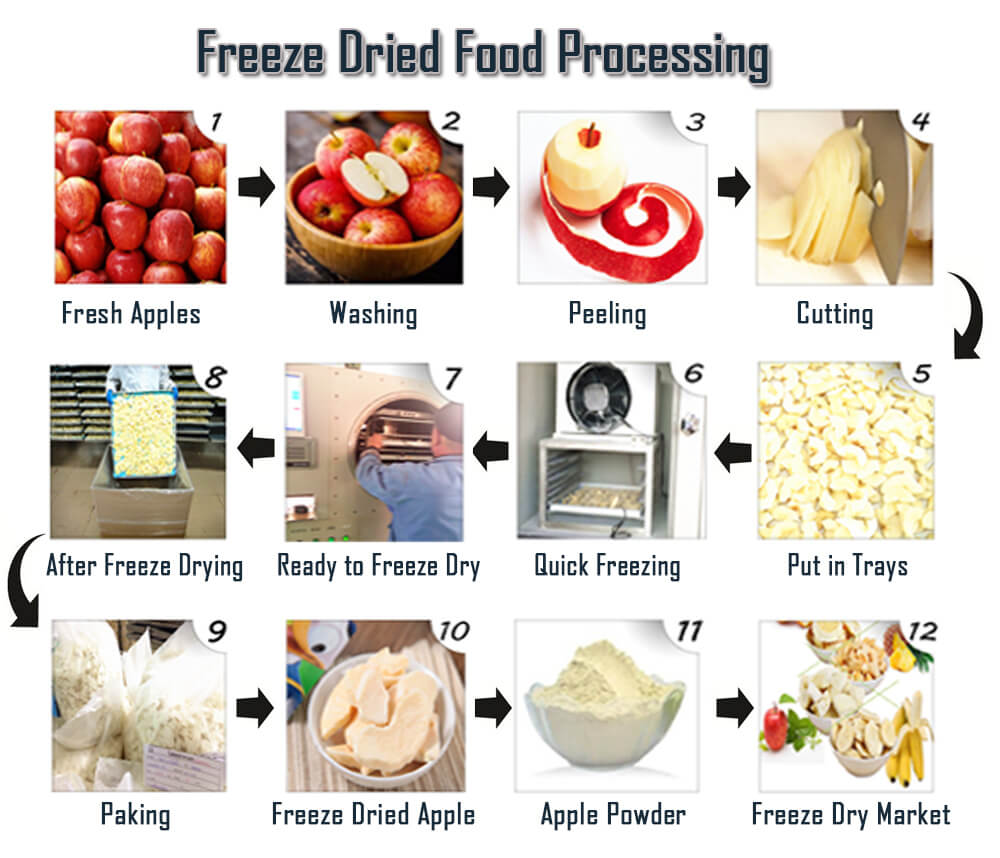

Using a freeze dryer involves: 1. Preparing fruit and loading it onto trays. 2. Placing trays in the freeze dryer. 3. Selecting the appropriate pre-set or custom drying cycle on the machine. 4. Letting the machine run its automated process. 5. Checking for complete dryness before packaging.

As a company that has specialized in laboratory and production equipment for over 16 years, we design our freeze dryers for ease of use without compromising on performance. Our ISO9001 and CE certifications reflect our commitment to quality and user satisfaction. Here's a breakdown of the typical steps when using one of our machines, or any similar modern freeze dryer:

Step-by-Step Guide:

-

Fruit Preparation: As we discussed, wash, slice, and pre-treat your fruit if needed. This initial step is crucial.

-

Loading Trays: Arrange the prepared fruit in a single layer on the freeze dryer trays. Avoid piling the fruit, as this will lead to uneven drying. Ensure pieces are not touching too much if possible. Our trays are designed for maximum capacity while ensuring good airflow.

-

Pre-Freezing (If not done by machine): Some home freeze dryers and many lab/industrial ones have a pre-freezing cycle built in. If not, or if you want to speed up the process, you can pre-freeze your trays of fruit in a separate deep freezer until solid (usually -18°C or 0°F, or colder if possible). Many of our ZZKD models offer integrated pre-freezing.

-

Loading the Freeze Dryer: Carefully place the loaded trays into the freeze dryer chamber. Close the door securely to ensure a proper vacuum seal.

-

Starting the Cycle: This is where our user-friendly interfaces come in. Most modern freeze dryers, including ours, have intuitive touch screens or control panels. You might select a pre-programmed cycle for specific fruits or set custom parameters for temperature, vacuum, and time if you're an advanced user. Our technical team often helps customers optimize these settings.

-

Monitoring the Process: The machine will then automatically run through the freezing, primary drying, and secondary drying stages. Our freeze dryers often display the current stage, temperature, and vacuum level. There's usually no need to interfere. A typical cycle can take 20-40 hours, depending on the fruit and the load.

-

Checking for Dryness: Once the cycle is complete, it's vital to check if the fruit is fully dried. Pieces should be lightweight, brittle, and show no signs of cold spots or moisture. Break a few larger pieces in half to inspect the center. If still moist, you can often add a few more hours of drying time.

-

Conditioning and Packaging: Once confirmed dry, let the fruit cool to room temperature in a dry environment (or directly from the machine if it has a cool-down phase). Then, immediately package it in airtight containers.

We've always emphasized robust construction and reliable automation in our freeze dryers, which means customers can trust the machine to do its job effectively. This makes the entire process much simpler and more reliable than one might think.

Why is Using a Specialized Freeze Dryer Better Than DIY Methods?

Thinking of trying a DIY freeze-drying setup to save money? Concerned it might be too complicated or unsafe? Specialized machines offer quality, safety, and efficiency that DIY can't match.

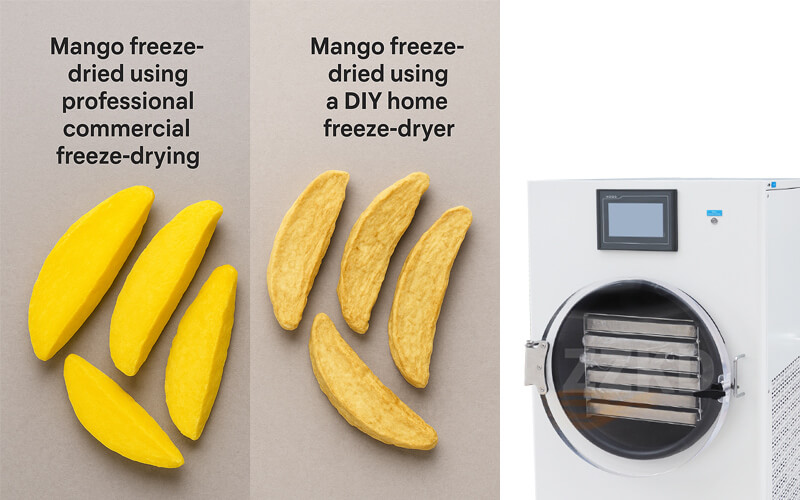

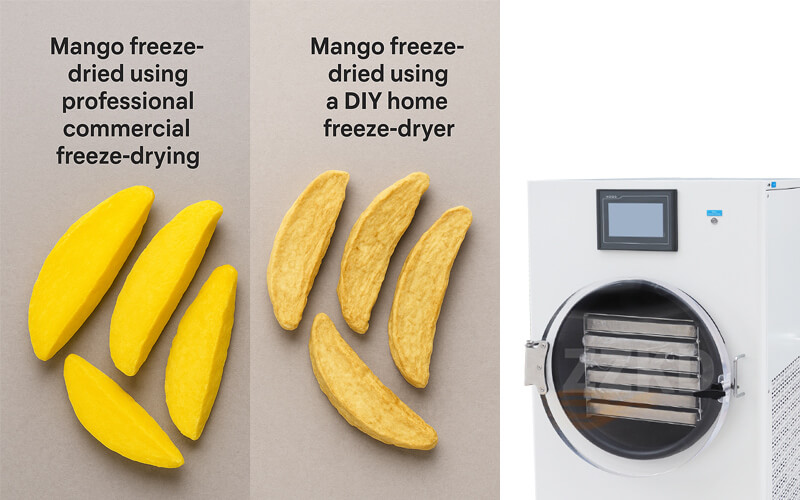

Specialized freeze dryers provide precise temperature and vacuum control essential for true sublimation. This ensures food safety, optimal nutrient retention, proper texture, and long shelf life, which are very difficult and often unsafe to achieve with DIY methods.

While the idea of a DIY freeze dryer might seem appealing, the reality is that achieving true, safe, and effective freeze-drying requires precise control that homemade setups typically can't offer. As a manufacturer with CE and ISO9001 certifications, we build our equipment to strict standards for safety and performance. Here’s why investing in a dedicated freeze dryer, like those we at Zhengzhou Keda Machinery and Instrument Equipment Co., Ltd. produce, is the better choice:

Key Advantages of Specialized Freeze Dryers:

-

Precise Temperature Control: True freeze-drying requires maintaining the product below its triple point during primary drying. Our machines have sophisticated cooling systems and sensors to achieve and maintain these very low temperatures (often -40°C to -50°C or lower for the condenser) and control shelf heating accurately. DIY methods often struggle with this, leading to melting instead of sublimation, which results in a poor-quality, shrunken product.

-

Deep Vacuum Levels: A strong vacuum is essential for sublimation to occur efficiently. Professional freeze dryers are equipped with powerful vacuum pumps and sealed chambers to reach and maintain the necessary low pressures (typically 100-600 milliTorr). DIY setups using items like dry ice and a vacuum sealer rarely achieve adequate or consistent vacuum.

-

Efficiency and Speed: Our commercial and lab-grade freeze dryers are designed for optimal energy efficiency and processing speed. The controlled environment ensures the fastest possible drying time while maintaining product quality. DIY methods are usually very slow and inefficient.

-

Safety: Working with deep vacuums and extreme temperatures carries risks if not managed properly. Our freeze dryers are built with safety features, durable materials, and undergo rigorous testing. DIY setups can pose risks of implosion or other hazards. We've seen the importance of safety through our 16 years of international export experience.

-

Consistent, High-Quality Results: With a specialized freeze dryer, you get consistently excellent results: perfectly preserved texture, color, flavor, and nutrients. DIY methods often lead to case hardening (dry outside, wet inside), poor rehydration, or even spoilage.

-

Ease of Use and Automation: Modern freeze dryers are largely automated, with user-friendly controls. As I mentioned, many of our models come with pre-set programs. This takes the guesswork out of the process.

I once spoke with a research lab that initially tried a makeshift setup. They quickly realized the inconsistencies were harming their research. After switching to one of our specialized lab freeze dryers, they achieved the reliable, repeatable results they needed. For serious preservation, research, or commercial production, a dedicated freeze dryer is an indispensable tool.

|

|

|

Drying area (m 2 ): 0.1 |

Tray size (mm): 145*275 |

|

Capacity (kg): 2-3 |

Condenser temperature (°C): ≤-35 |

|

|

|

Drying area (m 2 ): 0.3 |

Tray size (mm): 205*385 |

|

Capacity (kg): 3 |

Condenser temperature (°C): ≤-50 |

How Can You Store Your Homemade Freeze-Dried Fruit for Maximum Freshness?

You've successfully freeze-dried your fruit, but how do you keep it perfect? Worried it might go stale or absorb moisture? Proper storage is simple and ensures long-lasting quality.

Store freeze-dried fruit in completely airtight containers, such as Mylar bags with oxygen absorbers, or vacuum-sealed glass jars. Keep them in a cool, dark, and dry place to prevent moisture absorption and degradation from light or heat.

The fantastic thing about freeze-dried fruit is its incredibly long shelf life, but only if stored correctly. The main enemies are moisture, oxygen, and light. As a company that helps clients produce high-quality preserved goods, we always stress the importance of this final step. Here’s how we advise our customers to store their valuable freeze-dried products:

Best Practices for Storing Freeze-Dried Fruit:

|

Storage Factor |

Recommendation |

Why It's Important |

|

Containers |

Mylar bags are ideal. Glass jars with airtight lids (preferably vacuum-sealed) are also excellent. Avoid standard plastic bags or containers that are not truly airtight. |

Prevents moisture and oxygen from entering. Mylar also blocks light. |

|

Oxygen Absorbers |

Always use an appropriately sized oxygen absorber in each Mylar bag or jar. |

Removes residual oxygen, preventing oxidation, preserving flavor, color, and nutrients, and inhibiting aerobic bacterial growth. |

|

Moisture Control |

Ensure fruit is completely dry before storing. The storage container must be impermeable to moisture. |

Even a tiny amount of moisture can lead to spoilage or rehydration, ruining the texture. |

|

Light Exposure |

Store in a dark place like a pantry, cupboard, or use opaque containers (like Mylar bags). |

Light can degrade vitamins and cause discoloration over time. |

|

Temperature |

A cool, stable temperature is best. Avoid attics or garages with extreme temperature swings. Room temperature or cooler is good. |

Heat can accelerate degradation processes and affect texture. |

|

Handling |

Handle freeze-dried fruit gently as it can be brittle. Ensure hands are dry when packaging. |

Prevents crushing and introducing moisture. |

← Swipe Left and Right to View the Table→

When properly stored, freeze-dried fruit can last for many years – some say up to 25 years or more! I've personally tasted fruit that was freeze-dried and stored for 5 years using these methods, and it was still crisp and flavorful. The quality achieved by using a reliable freeze dryer, like those we manufacture at ZZKD, provides a product that is inherently more stable and suitable for long-term storage. It’s truly an amazing way to preserve the harvest or create lightweight, nutritious food for any situation.

Conclusion

Making freeze-dried fruit is an accessible and rewarding process with the right equipment and knowledge. It preserves flavor, nutrients, and offers incredible shelf life for your favorite fruits.

Products

Products