Low temperature spray drying technology is transforming the way industries preserve the quality and bioactivity of heat-sensitive materials. Traditionally, spray drying involves converting liquid or slurry into a dry powder by rapidly drying it with hot gas. However, when dealing with products such as certain pharmaceuticals, probiotics, or delicate food ingredients, high temperatures can damage nutrients or active compounds.

This is where low temperature spray drying technology comes into play. By reducing inlet and outlet air temperatures, often in combination with vacuum-assisted drying, this method preserves volatile components and enhances final product quality. According to a 2022 study by the American Institute of Chemical Engineers, low-temperature drying can improve the retention of bioactive compounds by up to 40% compared to conventional drying.

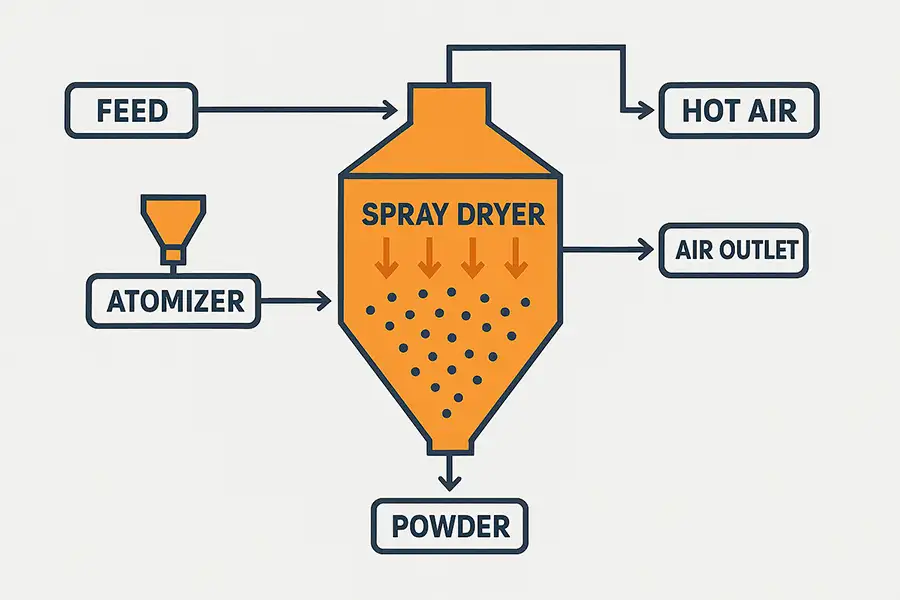

How Low Temperature Spray Drying Works

The process begins by atomizing the liquid feed into fine droplets. In a low-temperature setup, the drying air is pre-conditioned to a lower starting temperature — sometimes 60–90°C compared to the 150–200°C typical in standard spray drying. This is often complemented by reduced pressure to accelerate moisture removal at lower thermal loads.

Specialized spray dryer machines, like those discussed in this guide on spray dryers, optimize airflow, droplet distribution, and heat transfer to ensure uniform drying without overheating.

Applications Across Industries

-

Food and Beverage – drying milk, coffee, fruit extracts while retaining flavor & nutrition.

-

Pharmaceuticals – preserving drug stability and increasing shelf-life.

-

Chemicals – producing fine powders for catalysts, polymers, and nanomaterials.

-

Probiotics & Nutraceuticals – maintaining viability of beneficial microorganisms.

Advantages of Low Temperature Spray Drying

Why should industries adopt this method? Here are the main benefits:

|

Advantage |

Description |

|

Better Retention of Active Compounds |

Reduces thermal degradation of vitamins, probiotics, and flavors. |

|

Improved Product Color and Solubility |

Gentle heat prevents discoloration and maintains rehydration properties. |

|

Less Energy in Some Processes |

Potential savings when combined with moisture pre-removal steps. |

|

Enhanced Safety for Heat-Sensitive Formulations |

Minimizes risk of chemical changes and oxidation. |

Why not always use low temperature spray drying instead of traditional methods?

While it offers clear quality benefits, low temperature spray drying typically has slower throughput and may require more specialized equipment, increasing capital investment. For many robust, heat-tolerant powders (like detergents), conventional methods remain cost-effective.

How does it compare to freeze drying in terms of cost and quality?

Freeze drying often yields maximum retention of bioactives but is significantly more expensive and energy-intensive. Low temperature spray drying is a balanced choice — providing good retention at a fraction of the cost, suitable for large-scale industrial production.

Technological Innovations

Modern spray dryers incorporate advanced nozzle designs, real-time temperature monitoring, and variable pressure chambers. Some systems integrate spray drying safety features which are especially critical when handling organic solvents or bioactives.

According to MIT research, manufacturing sectors adopting AI-driven process control can expect up to a 20% increase in yield efficiency by 2030 — a trend now influencing spray dryer design.

Which industries are expected to benefit most from this technology in the coming decade?

Food supplements, plant-based protein powders, specialty chemicals, and biotechnology sectors will likely see the greatest gains. As consumer demand for natural, minimally processed ingredients grows, low temperature spray drying's market share is expected to rise.

Conclusion

Low temperature spray drying technology is bridging the gap between high-quality product preservation and industrial scalability. By preserving fragile compounds, reducing thermal damage, and improving final product quality, it stands as a smart investment for forward-looking manufacturers. Whether producing infant formula, pharmaceutical powders, or botanical extracts, adopting this method can enhance both product value and consumer satisfaction.

To understand if this is right for your process, explore our guide to milk powder spray dryers for more practical insights.

Products

Products