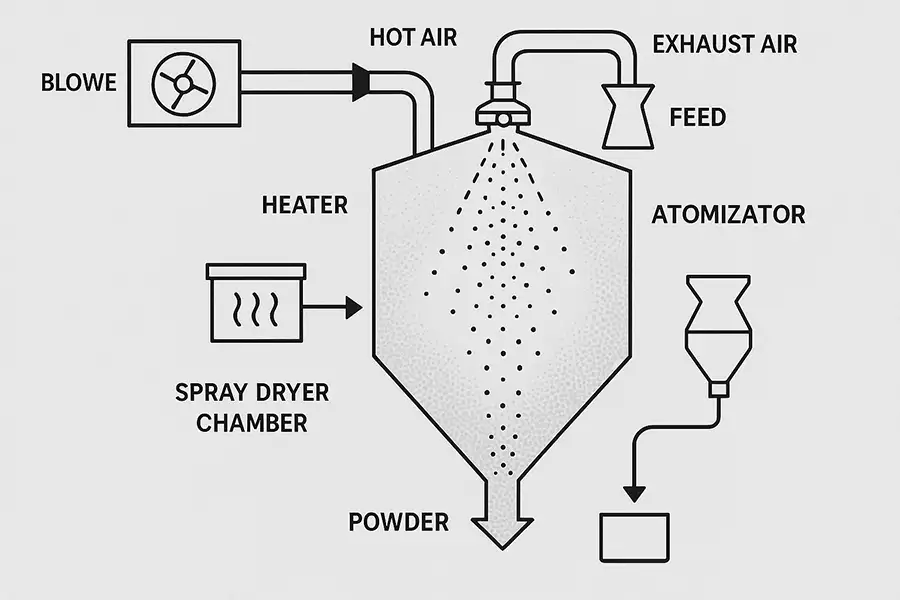

Spray drying is a widely used method for turning liquids into powders in industries such as food processing, pharmaceuticals, and chemicals. It works by atomizing a liquid into fine droplets and rapidly drying them with hot gas, resulting in a powder product. This technology offers numerous benefits, but it also has some limitations that must be considered before adoption.

What is Spray Drying?

Spray drying is a continuous process where a feed solution or slurry is sprayed into a hot drying medium. The droplets dry almost instantly, producing fine powders. This process is commonly used for products like milk powder, coffee, vitamins, and even certain pharmaceutical drugs. According to industry comparisons, spray drying can be more efficient than traditional dehydration methods for certain applications.

Why is spray drying so popular in the food industry?

Because it offers speed, uniformity, and scalability. It can produce powders with consistent particle size and moisture content, which is crucial for quality control in food production.

Advantages of Spray Drying

-

Speed: The drying process is extremely fast, often completed in seconds.

-

Consistency: Particle size and moisture content can be precisely controlled.

-

Scalability: Suitable for both small-scale laboratory use and large industrial production.

-

Product Quality: Maintains flavor, aroma, and nutritional value in many food products.

-

Versatility: Can handle heat-sensitive materials by adjusting process parameters.

For example, in dairy production, spray drying is used to make milk powder that retains most of the nutritional properties of fresh milk. The safety aspects of spray drying food have been studied extensively, showing that with proper controls, it is a safe and effective method.

Can spray drying handle heat-sensitive products?

Yes. By controlling inlet and outlet temperatures, spray drying can minimize thermal degradation, making it suitable for vitamins, enzymes, and probiotics.

Disadvantages of Spray Drying

-

High Energy Consumption: Requires significant energy input for heating air and atomizing liquids.

-

Equipment Cost: Spray dryers are expensive to purchase and maintain.

-

Complex Operation: Requires skilled operators and precise control of parameters.

-

Possible Nutrient Loss: Some sensitive compounds may degrade if not handled properly.

-

Dust and Waste: Fine powders can cause dust hazards if not managed.

While spray drying offers many benefits, the initial investment can be a barrier. As seen in milk powder spray dryer guides, the cost varies depending on capacity, automation, and material compatibility.

Is spray drying cost-effective in the long run?

In many cases, yes. Although initial costs are high, the efficiency, scalability, and product quality can lead to lower production costs over time compared to other drying methods.

Applications of Spray Drying

|

Industry |

Example Products |

Benefits |

|

Food & Beverage |

Milk powder, coffee, flavorings |

Retains flavor and nutrients |

|

Pharmaceutical |

Antibiotics, vitamins |

Controlled particle size for dosage |

|

Chemical |

Detergents, catalysts |

Uniform particle distribution |

Authoritative Insights

According to an MIT study on industrial automation, AI and advanced manufacturing technologies are expected to replace up to 30% of jobs by 2030. Spray drying, with its automation potential, fits into this trend, enabling companies to produce more with fewer labor costs while maintaining high quality standards.

Conclusion

Spray drying is a powerful technology with clear benefits for many industries. However, it requires careful consideration of costs, energy use, and product requirements. For businesses seeking high-volume, consistent powder production, spray drying remains one of the best options available.

Learn more about our spray drying solutions and how they can benefit your production line.

Products

Products