Spray drying is a widely used method of turning liquid materials into dry powder form in a single, quick operation. This process is particularly important in the food, pharmaceutical, and chemical industries. By atomizing a liquid into tiny droplets and rapidly drying them with hot air or gas, spray drying creates consistent and fine powders that have a long shelf life and are easy to transport and store.

The Basics of Spray Drying

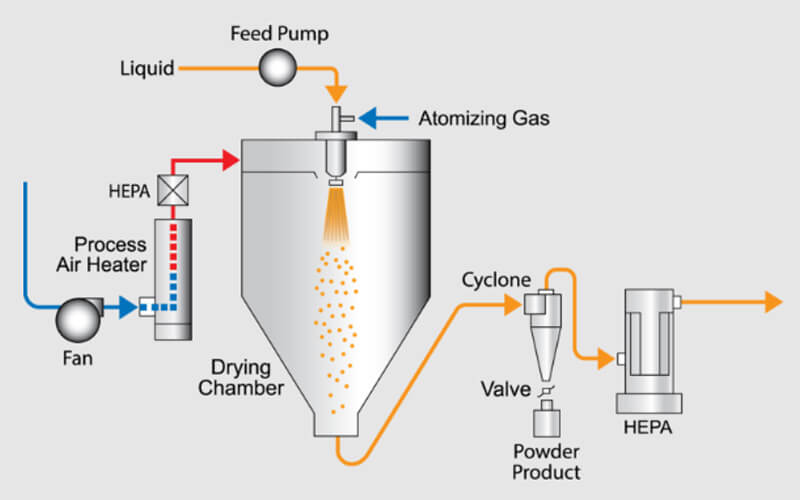

At its core, spray drying involves three main steps: atomization, drying, and collection. First, the liquid feed (which could be a solution, suspension, or emulsion) is sprayed into a hot air chamber using a spray dryer. As the fine droplets move through the chamber, moisture rapidly evaporates due to the high temperature. Finally, the dried particles are collected from the air stream, typically using cyclones or bag filters.

Author’s Note: According to a study by the Massachusetts Institute of Technology, technological advancements like AI are expected to automate up to 30% of industrial processes, including some aspects of drying, by 2030.

Applications of Spray Drying

Spray drying is used in various industries:

-

Food industry: Production of milk powder, coffee, flavors, and food additives.

-

Pharmaceuticals: Creating stable powdered forms of drugs, probiotics, and vitamins.

-

Chemicals: Drying of polymers, ceramics, and catalysts.

Why is Spray Drying So Popular?

The main reasons include high speed, scalability, and the ability to handle heat-sensitive products. By instantly drying droplets, it minimizes heat damage and preserves product quality. This makes it an excellent choice for products that must retain flavor, color, or bioactivity.

What is the difference between spray drying and freeze drying?

Answer: While both methods convert liquids into solids, spray drying uses hot gas to rapidly evaporate moisture, producing powders in seconds. Freeze drying, on the other hand, freezes the product and removes water via sublimation under vacuum, which can take hours. Spray drying is faster and ideal for large-scale production, while freeze drying often yields higher product stability for sensitive items.

How Does a Spray Dryer Work?

The typical spray dryer consists of a feed pump, atomizer (nozzle or rotary wheel), drying chamber, and powder recovery system. Here’s a simplified breakdown:

-

Feeding: The liquid product is pumped into the atomizer.

-

Atomization: The atomizer breaks the liquid into fine droplets.

-

Drying: Hot air is introduced, quickly drying the droplets into fine particles.

-

Separation: The powder is separated from air using cyclones or filters.

Is spray drying safe for food products?

Answer: Yes, when properly operated, spray drying is recognized as safe for food applications. The key factors are the choice of materials, hygienic design, and process control. For instance, spray drying food safety guidelines help ensure compliance with necessary standards.

Advantages of Spray Drying

-

High drying speed and production rate

-

Uniform particle size distribution

-

Good control over product properties

-

Suitable for heat-sensitive materials

-

Continuous operation for large-scale manufacturing

Challenges of Spray Drying

Despite its advantages, some challenges include high energy consumption and equipment costs. The process may also produce low yields if feed preparation or operating parameters are not optimized.

Can spray drying be used for encapsulation?

Answer: Absolutely. Spray drying is one of the most widely used techniques to encapsulate flavors, essential oils, probiotics, and active pharmaceutical ingredients. It protects sensitive components from light, oxygen, and moisture, prolonging shelf life.

Real-World Example: Milk Powder Production

Milk powder production via spray drying begins by concentrating milk through evaporation, then atomizing it into a hot air stream, and finally collecting the powder. This allows for long-term storage without refrigeration while maintaining most of the nutritional qualities.

For a comparison of spray dry equipment types, see our guide on milk powder spray dryers.

Future of Spray Drying

With advancements in process control systems, energy recovery, and AI-based monitoring, spray drying is becoming more efficient and sustainable. Predictive maintenance reduces downtime while new nozzle designs improve powder quality and yield. According to industry trends, global demand for spray drying equipment is expected to grow steadily, especially in emerging markets for food and pharmaceuticals.

Spray drying transforms liquids into stable powders quickly, making it indispensable in modern manufacturing.

Products

Products