Spray drying is one of the most efficient and widely used drying methods in both the food and chemical industries. But what exactly is a spray dried powder? Simply put, it’s a fine, dry powder produced by rapidly drying a liquid or slurry through a hot gas. This process transforms liquids into powders in seconds, preserving the material’s stability, flavor, and functional properties.

Understanding the Spray Drying Process

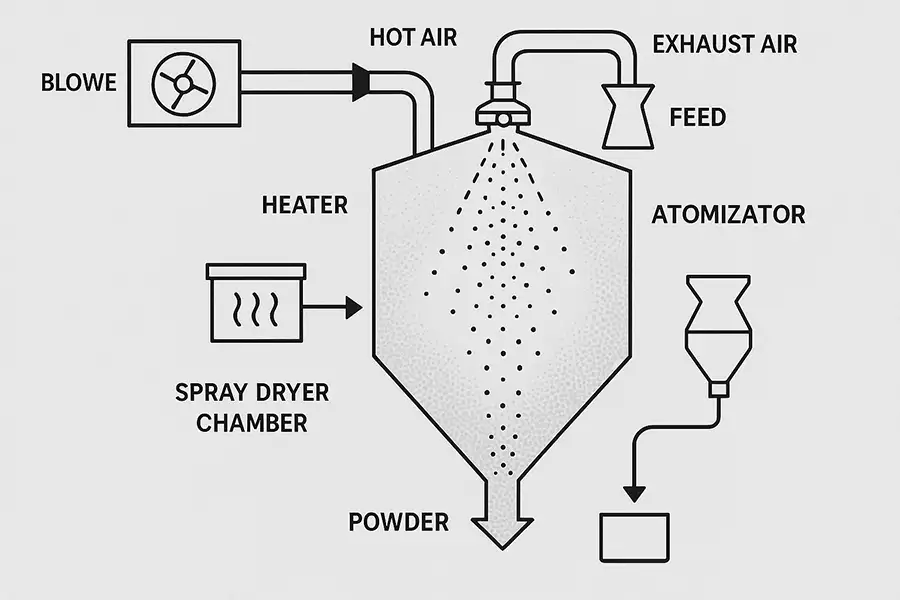

The spray drying process begins with a liquid feed—this could be a solution, suspension, or emulsion. The liquid is atomized into tiny droplets using a nozzle or rotary atomizer. These droplets are then introduced into a chamber containing hot air. As the droplets come into contact with the air, the moisture evaporates almost instantly, leaving behind dry particles that form the spray dried powder.

What makes spray drying different from other drying methods like freeze drying or oven drying?

Spray drying is much faster and more suitable for large-scale production. Unlike freeze drying, which operates at low temperatures and can take hours, spray drying completes in seconds. The process also allows better control over particle size and moisture content, making it ideal for powders used in food, pharmaceuticals, and chemicals. For example, milk powder and instant coffee are both spray dried products.

Applications of Spray Dried Powders

Spray dried powders are everywhere—from the instant coffee in your kitchen to the powdered milk used in baking mixes. In the chemical industry, spray drying is used to produce catalysts, ceramics, and polymers. In pharmaceuticals, it helps create stable formulations of heat-sensitive drugs.

According to a study by the National Institute of Standards and Technology (NIST), spray drying helps reduce product degradation by up to 40% compared to conventional drying, making it a preferred method for preserving sensitive compounds.

Key Benefits of Spray Drying

-

Rapid drying and high throughput

-

Uniform particle size distribution

-

Enhanced product stability

-

Scalability for industrial applications

-

Improved solubility and rehydration properties

Is spray drying safe for food applications?

Yes, spray drying is considered safe and is used extensively in food processing. The process operates under controlled conditions, ensuring that the product’s nutritional and sensory qualities are maintained. For more details, see

Is Spray Drying Food Safe?.

How Spray Dryers Work

A spray drying machine consists of several key components: an atomizer, a drying chamber, a heat source, and a collector. The atomizer breaks the liquid into fine droplets. The drying chamber provides a controlled environment for moisture evaporation. The hot air source supplies the necessary heat, and the collector gathers the final powder.

Modern spray dryers are equipped with advanced control systems that monitor temperature, airflow, and particle size. These features ensure consistent product quality and energy efficiency.

Spray Drying vs. Other Techniques

Compared to freeze drying or vacuum drying, spray drying offers unmatched speed and cost-effectiveness. For industries requiring continuous production, such as dairy, pharmaceuticals, and chemicals, spray drying remains the go-to method. You can explore more about drying technologies in our article on Guide to Milk Powder Spray Dryers.

How does spray drying technology impact sustainability?

Spray drying is energy-efficient and minimizes waste. Many modern systems recycle hot air and optimize heat transfer, reducing the overall carbon footprint. According to a report by the International Energy Agency, optimizing drying processes can cut industrial energy use by up to 20% globally.

Choosing the Right Spray Dryer

When selecting a spray dryer, consider the product type, desired particle size, and production capacity. Laboratory-scale spray dryers are ideal for research and small batches, while industrial models support continuous operation. For laboratory applications, check out lab spray dryers for detailed insights.

Conclusion

In summary, a spray dried powder is the result of a high-speed, efficient process that transforms liquids into stable, fine powders. The technology’s flexibility, safety, and scalability make it indispensable across industries—from food and pharmaceuticals to chemicals and materials science. As global demand for powdered products continues to rise, spray drying machines will remain vital for innovation and quality production.

For more information on drying technologies or to explore advanced equipment, visit ZZKD Instrument’s Spray Drying Solutions.

Products

Products