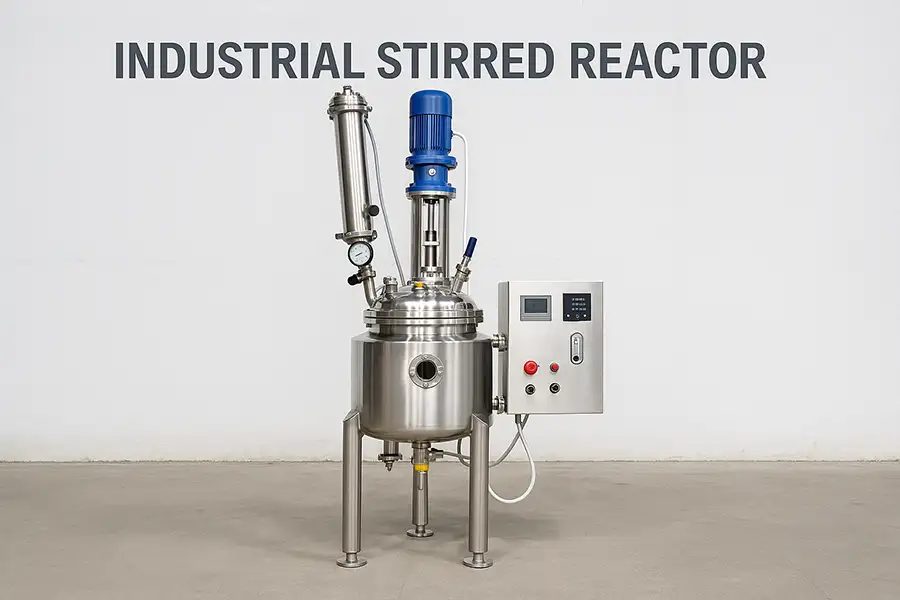

A stirred stainless steel reactor is a versatile piece of industrial equipment used extensively in chemical processing, pharmaceuticals, food production, and materials engineering. These reactors combine the durability of stainless steel with the efficiency of mechanical stirring to ensure uniform mixing, heat transfer, and reaction control.

What is a Stirred Stainless Steel Reactor?

In simple terms, this type of reactor is a tank or vessel made from corrosion-resistant stainless steel, equipped with an internal stirring mechanism. The stirrer ensures that reactants are evenly distributed, preventing hotspots and ensuring consistent product quality.

Stainless steel grades like 304 and 316 are commonly used due to their excellent corrosion resistance, mechanical strength, and ability to withstand high temperatures and pressures.

What makes stainless steel the preferred choice for industrial reactors?

Stainless steel offers superior corrosion resistance, durability, and hygiene compared to other materials. It can handle acidic, alkaline, and high-temperature environments without degrading, making it ideal for chemical and food industries.

Working Principle

The working principle of a stirred stainless steel reactor involves continuous agitation of the contents to promote mixing and reaction efficiency. Heat exchangers or jackets around the vessel allow precise temperature control, while sensors monitor pressure, temperature, and pH.

According to a study by MIT, automation and AI integration in industrial equipment are expected to increase efficiency by up to 30% by 2030. Modern reactors are increasingly adopting automated controls for stirring speed, temperature, and pressure.

Applications

-

Pharmaceutical synthesis

-

Polymerization reactions

-

Food processing (e.g., dairy pasteurization)

-

Petrochemical refining

-

Biochemical fermentation

For example, in continuous stirred tank reactors, the stirred stainless steel design ensures constant product output with uniform quality.

Can stirred reactors be used for both batch and continuous processes?

Yes. Stirred stainless steel reactors can be configured for batch processing, where all reactants are loaded and processed together, or continuous processing, where reactants are fed and products removed simultaneously.

Advantages

-

Excellent corrosion resistance

-

Uniform mixing and temperature distribution

-

High mechanical strength

-

Ease of cleaning and sterilization

-

Compatibility with automation systems

Many modern units integrate with stainless steel jacketed reactors for enhanced temperature control.

Design Considerations

When selecting a stirred stainless steel reactor, engineers consider:

-

Volume capacity

-

Material grade

-

Type of stirrer (propeller, paddle, turbine)

-

Pressure rating

-

Temperature range

For specialized chemical synthesis, high-pressure designs like autoclave reactors are preferred.

Maintenance and Safety

Regular inspection of seals, stirrer blades, and temperature sensors ensures optimal performance. Safety features include pressure relief valves, emergency shutdown systems, and explosion-proof motors.

How often should a stirred stainless steel reactor be inspected?

Typically, a full inspection is recommended every 6–12 months, depending on usage intensity and the nature of the chemicals processed.

Conclusion

Stirred stainless steel reactors are indispensable in modern industry due to their durability, efficiency, and adaptability. Whether in pharmaceuticals, food processing, or petrochemicals, these reactors deliver consistent results while ensuring safety and compliance.

By integrating advanced control systems and maintaining regular inspections, industries can maximize productivity and extend equipment lifespan.

Products

Products