Discover the Revolutionary Process That Turns Liquids Into Shelf-Stable Powders!

From your morning coffee to life-saving medicines, spray drying is the invisible hero transforming liquids into convenient powders. Let's dive into this fascinating process that's revolutionizing industries worldwide!

The Magic Behind Powder Transformation

Ever wonder how milk becomes powder, coffee transforms into instant crystals, or medicine converts into dissolvable packets? The answer lies in a remarkable process called spray drying - the most efficient method to convert liquids into powders while preserving their essential properties.

Spray drying works on a simple but brilliant principle: turn liquid into tiny droplets and expose them to hot air. The water evaporates instantly, leaving behind pure powder. This method preserves heat-sensitive ingredients better than any other drying technique, making it perfect for food, pharmaceuticals, and industrial applications.

But how exactly does this transformation happen without damaging sensitive ingredients?

The secret is in the speed! Spray drying happens in seconds, much faster than other drying methods. The liquid is atomized into micro-droplets that have enormous surface area relative to their volume. When these tiny droplets meet hot air, the water evaporates almost instantly, "freezing" the molecular structure before heat can damage sensitive components. This is why spray drying preserves vitamins in food and maintains the efficacy of pharmaceutical compounds.

The Step-by-Step Spray Drying Process

Let's break down this incredible transformation into simple steps:

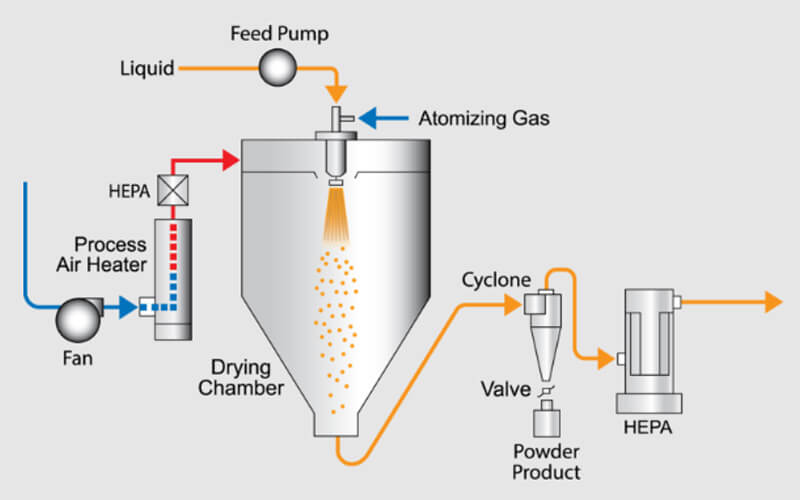

Atomization

The liquid is pumped through a specialized nozzle that transforms it into a fine mist of microscopic droplets. This creates maximum surface area for efficient drying.

Hot Air Contact

These droplets meet a stream of hot air (up to 200°C) in a drying chamber. Water evaporates instantly from the droplet surface.

Powder Formation

As water evaporates, solids in the liquid form a protective shell around remaining moisture, creating hollow powder particles.

Separation

The powder is separated from the moist air using cyclones or filters. The result? Ultra-fine, free-flowing powder ready for packaging!

Where Spray Drying Transforms Industries

This remarkable technology touches nearly every aspect of modern life. Here's where spray drying makes a massive impact:

From milk powder to instant coffee, soup mixes to flavor enhancers, spray drying creates shelf-stable products that retain nutritional value and taste. The process is particularly important for milk powder production where preserving proteins is critical.

Life-saving medicines, antibiotics, and vaccines are transformed into stable powders that can be easily reconstituted. Spray drying enables precise dosing and extends shelf life dramatically.

Detergents, ceramics, catalysts, and pigments all benefit from spray drying. The process creates uniform particle sizes that improve product performance and consistency.

Enzymes, probiotics, and other sensitive biological materials are preserved through spray drying. The technique maintains biological activity while creating stable products.

Is spray drying safe for food and pharmaceutical products?

Absolutely! When properly executed, spray drying is one of the safest preservation methods available. The high temperatures actually destroy pathogens while the rapid process preserves nutrients. Modern spray dryers are designed with food safety standards in mind, using sanitary materials and closed systems that prevent contamination. Pharmaceutical-grade spray dryers meet even stricter GMP (Good Manufacturing Practice) requirements.

The Incredible Benefits of Spray Drying

Why has spray drying become the gold standard for liquid-to-powder conversion? The advantages speak for themselves:

-

Lightning Speed: Complete drying in seconds rather than hours or days

-

Gentle Preservation: Maintains heat-sensitive components like vitamins and enzymes

-

Perfect Consistency: Creates uniform, free-flowing powders with controlled particle size

-

Reduced Weight: Powdered products are up to 90% lighter than their liquid counterparts

-

Extended Shelf Life: Eliminates water activity that causes spoilage

-

Easy Reconstitution: Powders dissolve instantly when mixed with liquid

"According to the International Dairy Federation, spray drying preserves up to 95% of the nutritional value in milk while reducing volume by 90%, making it one of the most efficient food preservation methods ever developed."

What about the cost? Is spray drying affordable for smaller operations?

Great question! While industrial-scale spray dryers represent a significant investment, modern technology has made smaller, more affordable units accessible. The cost-effectiveness comes from the incredible efficiency - spray drying processes large volumes quickly with minimal energy waste. For many businesses, the savings in transportation, storage, and shelf-life extension make spray dryers pay for themselves surprisingly quickly!

Saving Money Is The Last Word, And It Is Worth Investing In Buying!

When you calculate the long-term benefits, a spray dryer isn't an expense - it's a profit-generating investment! Consider these financial advantages:

90%

Reduction in transportation costs

75%

Longer shelf life for products

60%

Less storage space required

When you factor in reduced spoilage, expanded market reach, and premium pricing for convenience products, the ROI on spray drying equipment becomes undeniable. The technology pays for itself while opening new business opportunities!

The Future of Powder Technology

Spray drying continues to evolve with exciting innovations on the horizon. Nano-spray drying creates ultra-fine particles for advanced drug delivery systems. Encapsulation technology allows combining incompatible ingredients in a single powder. And sustainable spray drying techniques are reducing energy consumption by up to 40%!

As consumer demand for natural, preservative-free products grows, spray drying provides the perfect solution - combining ancient preservation wisdom with cutting-edge technology. From specialty dairy products to personalized medicine, the applications are expanding daily.

Ready to Transform Your Liquids Into Profitable Powders?

Discover how spray drying technology can revolutionize your product line and boost your bottom line. Explore our range of efficient, reliable spray dryers designed for businesses of all sizes.

Explore Spray Dryer Solutions

Products

Products