Ever felt overwhelmed by drying technologies? You're not alone! Two heavyweights dominate industrial drying: the spray dryer and the fluid bed dryer. Both turn liquids into powders, slurries into granules, and chaos into order... but which one deserves your investment? Let's cut through the jargon and break down their differences like a pro.

Meet the Contenders: How They Work

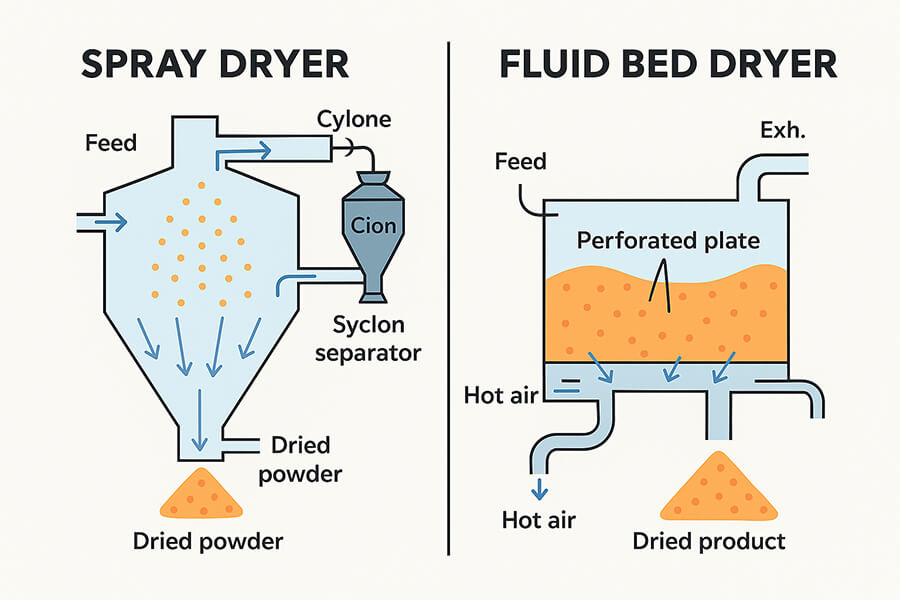

Spray Dryer: The Flash Artist

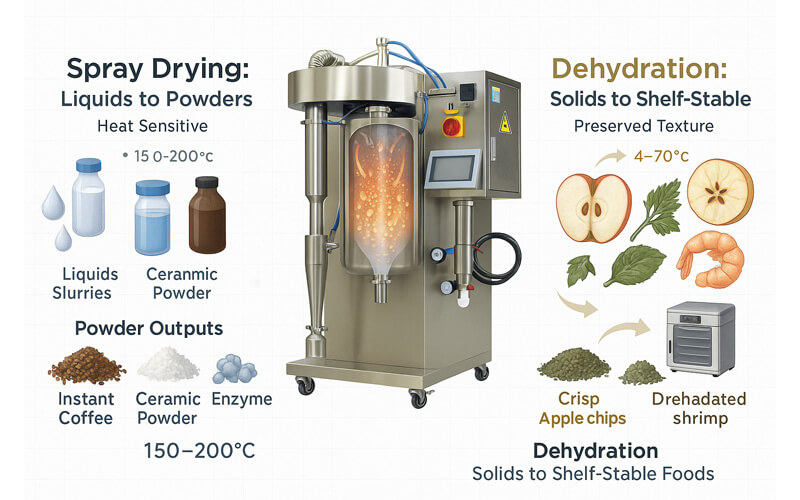

Imagine blasting liquid through a nozzle into a hot chamber—like turning water balloons into powdered rain in seconds. That's spray drying! Liquid feed gets atomized into tiny droplets that meet hot air (up to 400°C!). Water evaporates instantly, leaving behind bone-dry particles collected at the bottom.

What's the biggest advantage of this "instant drying" magic?

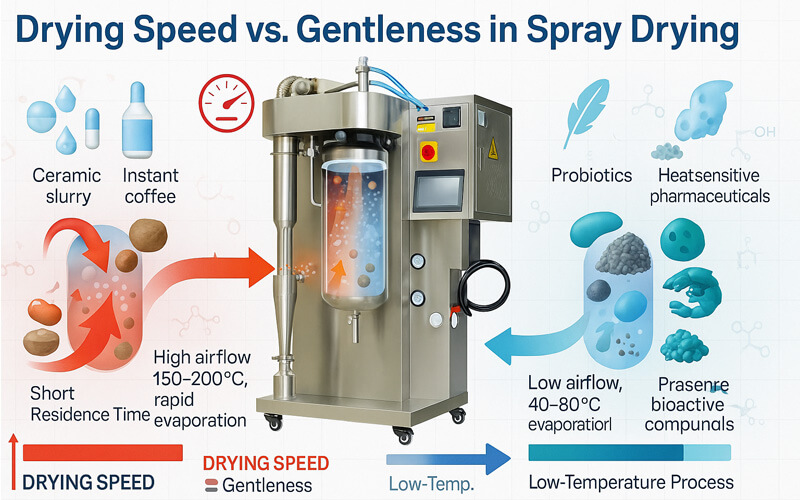

Thermal sensitivity? Not a problem! Even heat-sensitive stuff like milk or probiotics survives because drying happens fast. According to industry studies, spray drying preserves 95%+ of nutrients in dairy powders—no easy feat!

Fluid Bed Dryer: The Gentle Rocker

Picture wet granules floating on a cushion of hot air—like grains of sand dancing on a warm breeze. Air blows upward through a perforated plate, "fluidizing" solid particles. Moisture evaporates gradually as particles tumble in a controlled chaos. Perfect for turning clumpy cake mix into fluffy perfection!

Head-to-Head: The 5 Key Differences

|

Feature |

Spray Dryer |

Fluid Bed Dryer |

|

Input Material |

Liquids, slurries (milk, coffee extract) |

Wet solids, granules (pharma pellets, grains) |

|

Particle Size |

Fine powders (10-200 microns) |

Larger granules (100-5000 microns) |

|

Speed |

Lightning-fast (seconds) |

Minutes to hours |

|

Heat Sensitivity |

★★★★★ (Excels with delicate materials) |

★★★☆☆ (Risk of overheating if not controlled) |

|

Energy Use |

Higher (needs atomization + high heat) |

Lower (gentler airflow) |

Which dryer handles sticky, sugary liquids better?

Spray dryers win this round! Their instant drying prevents sugar from caramelizing on surfaces. Fluid beds? Sticky messes can clog the plate—ever tried drying honey? Nightmare! For candy or fruit powders, spray drying is king. (Freeze-drying also rocks for candy, but that’s another story!)

Cost Wars: Saving Money Is The Last Word!

Let’s talk cash. Spray dryers demand higher upfront costs—fancy nozzles, massive chambers, and energy-guzzling heaters. But here’s the twist: they’re cheaper per ton for large-scale production. MIT research shows that for outputs over 5 tons/day, spray drying costs drop 30% vs. fluid beds!

Fluid bed dryers? Budget-friendly starters. Less steel, simpler mechanics. Perfect for small batches or when you’re drying pre-formed granules. But watch out—longer drying times = higher labor costs.

Pro Tip: Pair them! Many plants use spray dryers first, then fluid beds for agglomeration. Boom—instant coffee that dissolves smoothly without sludge!

When to Choose Which? (No-BS Guide)

Pick a SPRAY DRYER if you…

• Work with liquids or slurries

• Need fine, consistent powders (think baby formula)

• Process heat-sensitive bio-actives

• Require high throughput (2+ tons/hour)

Choose a FLUID BED DRYER if you…

• Start with wet solids or granules

• Want to improve flowability (like tablet ingredients)

• Need gentle drying for fragile crystals

• Operate smaller batches or R&D trials

Can fluid bed dryers handle powders made by spray dryers?

Absolutely! It’s a power combo. Spray dryers make the powder; fluid beds agglomerate it into larger, non-dusty particles. Your workers (and lungs) will thank you. This hybrid approach dominates the food and pharma industries.

Beyond Drying: Hidden Perks

Spray dryers aren’t just dryers—they’re particle designers! Adjust the nozzle and voilà: hollow spheres for floatable fish feed or dense granules for paint pigments. Fluid beds? Masters of multitasking: drying, coating, granulating. Ever seen a vitamin pill with a candy shell? Thank fluid bed coating!

And maintenance? Fluid beds win. Fewer moving parts, easier cleaning. Spray dryer nozzles wear out like pencil erasers—budget for replacements.

Fun Fact: 70% of instant coffee is spray-dried. The rest? Freeze-dried for premium crunch. (Freeze-drying preserves aromas better, but costs 5x more!)

Verdict: It’s About Your Product’s DNA

No "best" dryer—only the best for your material. Liquids? Spray dryer. Granules? Fluid bed. Heat-sensitive? Spray. Tight budget? Fluid bed. And remember: hybrid systems exist for the best of both worlds!

Still torn? Ask yourself:

• Is my feed liquid or solid?

• What particle size do I need?

• How heat-sensitive is my product?

• What’s my production volume?

Armed with these answers, you’ll choose like a seasoned pro. And hey—if candy drying is your game, we’ve got a freeze-drying guide too!

Products

Products