Spray dryers have become an integral part of various industrial processes, offering efficient and rapid drying solutions. Understanding the common uses of spray dryers reveals their critical role in transforming liquids into powder form, a necessary step in many manufacturing sequences.

One of the primary common uses of spray dryers is in the food industry. Here, they play a crucial role in producing milk powder, coffee, tea, eggs, and cereals. The process involves atomizing the liquid food into a hot air stream, quickly drying it into a fine powder while retaining flavor and nutritional value. This method is particularly beneficial for extending the shelf life of perishable goods and for ease of transport and storage.

Another significant area where spray dryers are extensively used is in the pharmaceutical industry. Spray drying technology enables the production of consistent, fine powder, crucial for tablet manufacturing, encapsulation, and ensuring uniform dosage in pharmaceuticals. Lab scale spray dryers are particularly valuable in this sector for developing new drugs and formulations, allowing for small-batch testing and research.

Chemical industries also rely heavily on spray dryers. These devices are essential for producing detergents, polymers, and various chemical compounds. The spray drying process is favored for its ability to produce uniform particle sizes and for its efficiency in handling heat-sensitive chemicals, which is critical for maintaining the integrity of the final product.

In the ceramics industry, spray dryers find their use in producing fine, uniform ceramic powders used in making tiles, tableware, and sanitary products. The process ensures the homogeneity of the powder, a vital factor in achieving high-quality ceramic products.

Furthermore, the environmental sector benefits from spray dryers, especially in pollution control. They are used to dry sludges and aqueous waste, turning them into a dry, manageable form for disposal or further treatment.

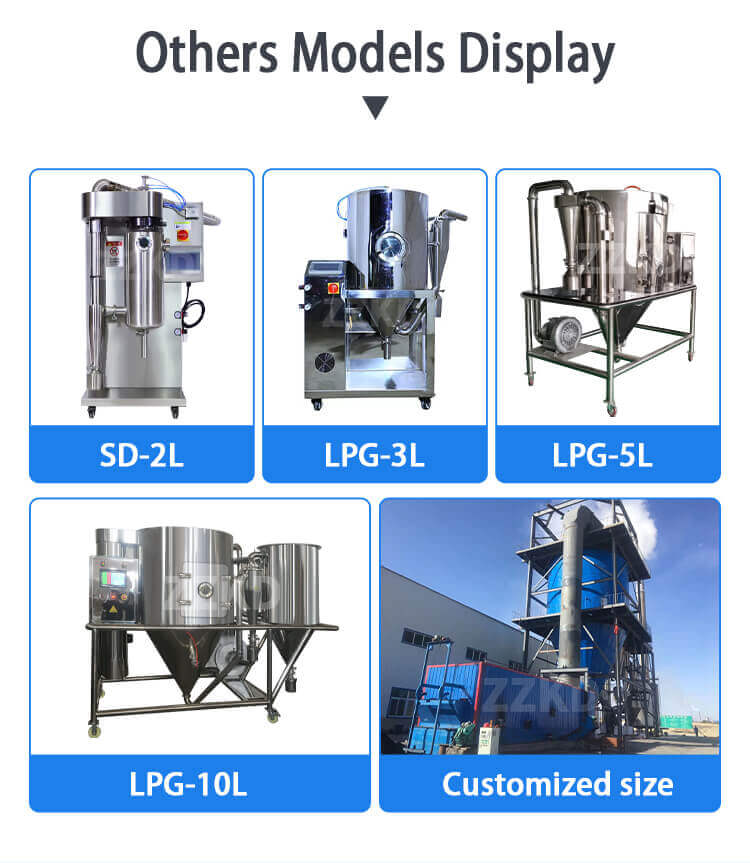

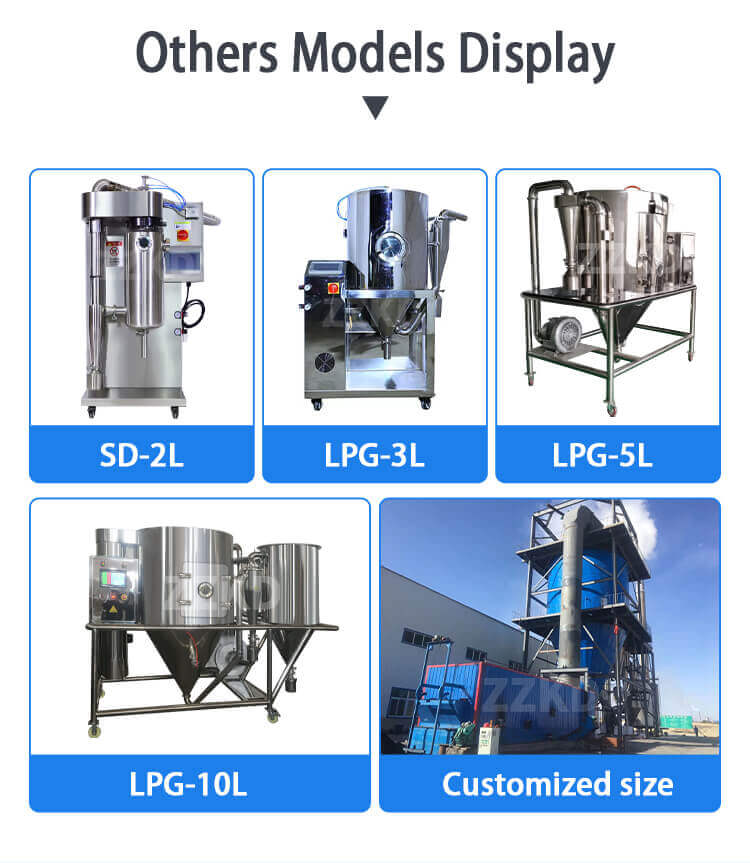

Lab scale spray dryers, a smaller version of the industrial models, are indispensable in research and development. They are used extensively in universities, research institutions, and small businesses for experimenting with new materials and processes on a smaller scale. These compact units offer the advantage of requiring minimal product quantities, making them cost-effective and ideal for trials and testing.

The common uses of spray dryers span across various industries, underscoring their versatility and efficiency in converting liquids into powders. From food to pharmaceuticals, chemicals to ceramics, and even environmental management, these machines play a pivotal role. The inclusion of lab scale spray dryers in this mix further extends the application of this technology, enabling innovation and experimentation in various fields.

Products

Products