The process of juice concentration is pivotal in the beverage industry, serving not only to enhance flavor and extend shelf life but also to optimize transportation and storage costs. Among the various methods employed for this purpose, wiped film distillation emerges as a particularly effective technique, offering significant advantages in terms of efficiency, quality preservation, and energy consumption. This article delves into the intricacies of wiped film distillation, underscoring its role as a superior method for producing high-quality juice concentrates.

Background on Juice Concentration Methods

Traditionally, juice concentration has relied on methods like thermal evaporation and freeze concentration. Thermal evaporation involves heating the juice to remove water, thereby increasing its concentration. Although effective, this method often leads to the degradation of heat-sensitive nutrients and flavors, a critical drawback in juice processing. Alternatively, freeze concentration, where water is frozen and removed as ice, preserves more of the juice’s natural qualities but at the cost of increased energy consumption and processing time.

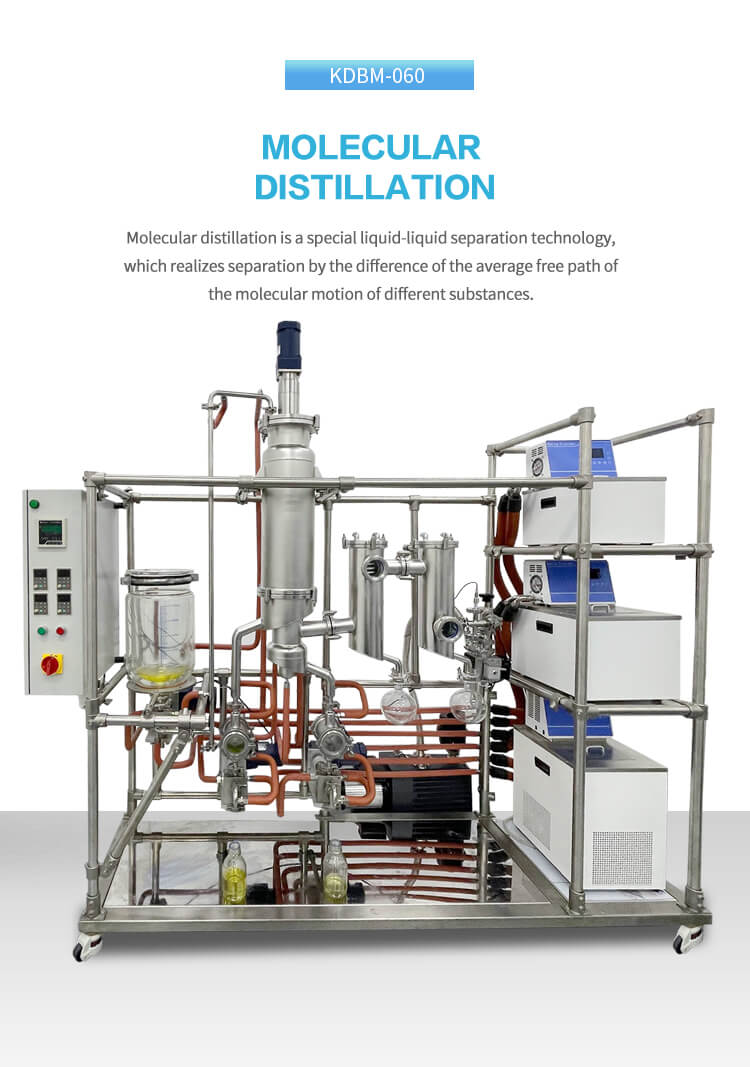

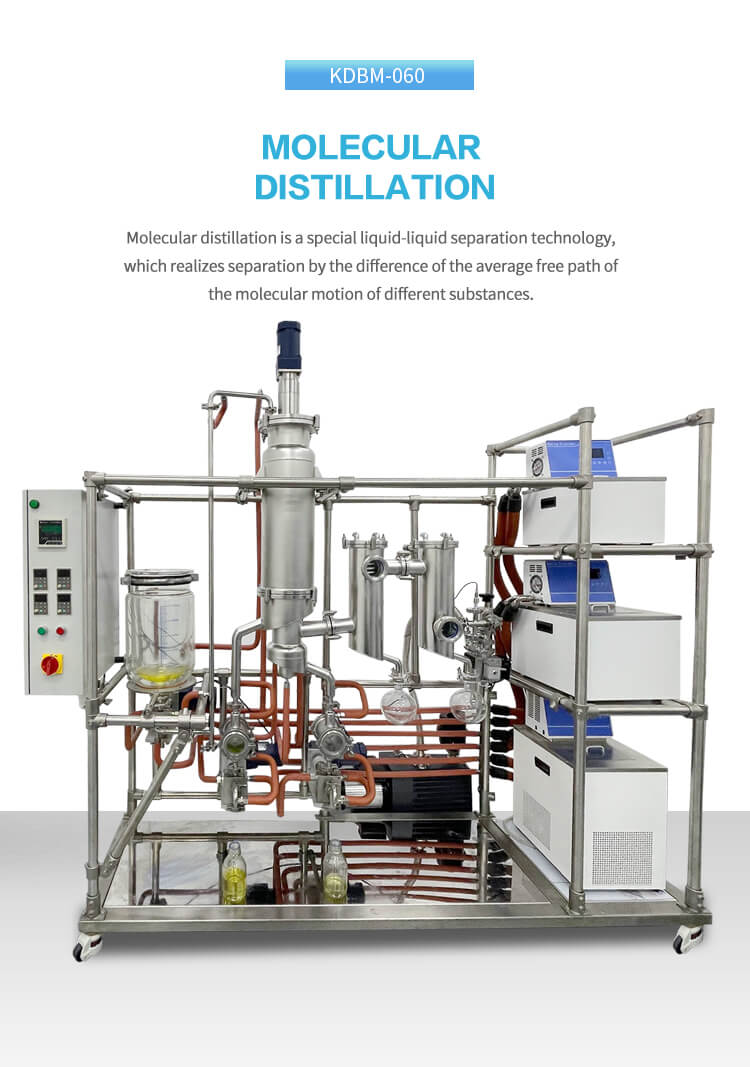

Fundamentals of Wiped Film Distillation

Wiped film distillation stands out as a modern alternative, addressing many of the limitations posed by traditional methods. At its core, this technique involves the evaporation of a liquid under reduced pressure, which allows for the process to occur at lower temperatures. This aspect is particularly beneficial for juice concentration, as it minimizes the thermal impact on sensitive flavors and nutrients.

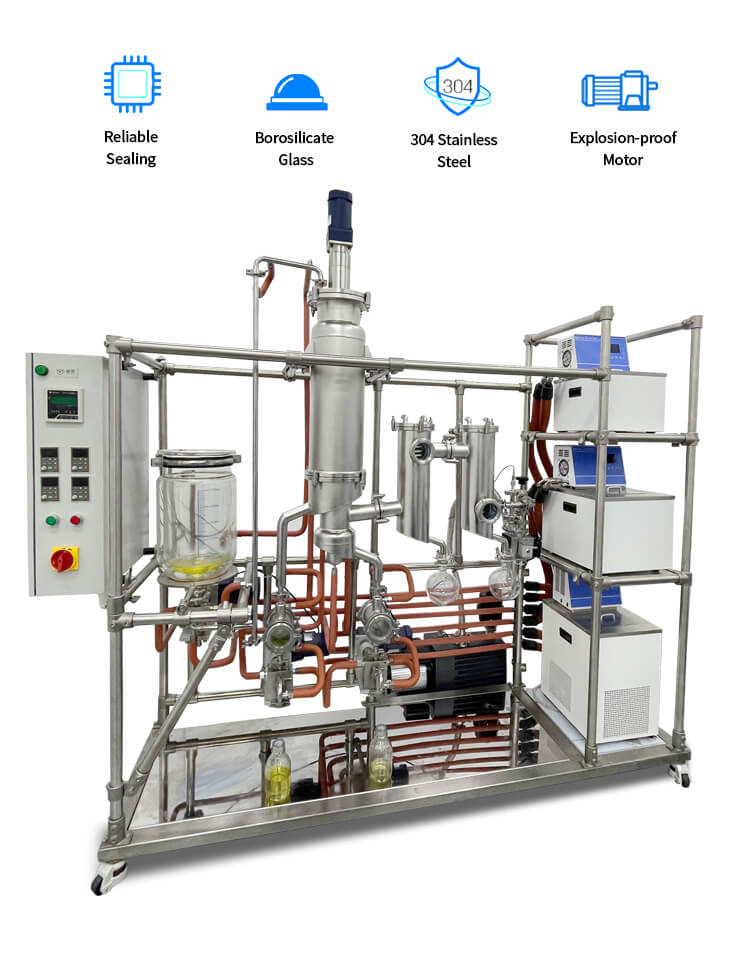

In a wiped film distillation system, the juice is introduced into a heated cylindrical column, equipped with a rotating wiper system. This wiper spreads the juice into a thin film along the heated surface, facilitating rapid and uniform evaporation. The evaporated components, primarily water, are then condensed and removed, leaving behind a more concentrated juice.

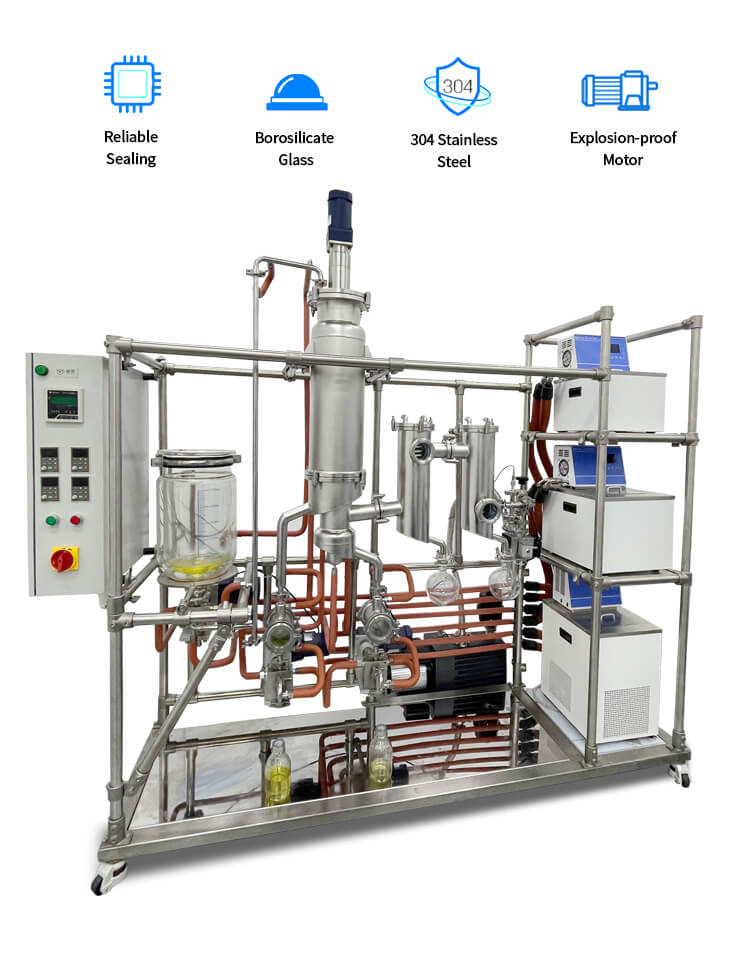

Technical Aspects of Wiped Film Distillation

The effectiveness of wiped film distillation hinges on several technical parameters. Temperature control is crucial; it must be high enough to facilitate evaporation but not so high as to degrade the juice quality. Similarly, maintaining an optimal pressure within the distillation column is vital for efficient evaporation and condensation.

The material of the distillation equipment also plays a significant role. It needs to be resistant to corrosion caused by fruit acids and capable of maintaining cleanliness to prevent contamination. Stainless steel is commonly used due to its durability and resistance to corrosion.

Advantages of Wiped Film Distillation for Juice Concentration

Wiped film distillation boasts several advantages over traditional concentration methods. First, its efficiency in separation is unparalleled, allowing for quicker processing times. This efficiency translates to higher throughput and, consequently, higher production capacities.

Moreover, the method excels in preserving the natural flavor and nutritional content of juices. By operating at lower temperatures, it significantly reduces the risk of thermal degradation, ensuring that the concentrate retains its original quality. This aspect is particularly important for high-end juices where flavor and nutritional value are paramount.

Energy consumption is another area where wiped film distillation shines. Compared to traditional methods, it requires less energy, which not only reduces operational costs but also aligns with the growing industry focus on sustainability.

Case and Practical Applications

Wiped film distillation has been successfully implemented in various industrial settings, particularly in the production of juice concentrates. For example, in the citrus juice industry, this method has been instrumental in preserving the delicate flavors and aromas that are typically lost in conventional concentration processes. By comparing the outcomes of wiped film distillation with other methods, industry reports have consistently highlighted superior flavor profiles and higher nutritional content in the final product.

Another application is seen in the concentration of exotic fruit juices, where the preservation of unique and delicate flavors is crucial. Wiped film distillation allows these juices to maintain their distinct characteristics, which might otherwise be compromised using traditional heat-based methods.

Click here to get "wiped film evaporator" price.

Challenges and Limitations

Despite its numerous advantages, wiped film distillation is not without its challenges. One significant hurdle is the initial capital investment. The cost of setting up a wiped film distillation system can be higher than traditional methods, posing a barrier for smaller producers. Moreover, the technical complexity of the system requires skilled operators and rigorous maintenance to ensure optimal performance.

Additionally, there are certain limitations regarding the types of juices that can be effectively concentrated using this method. For instance, juices with very high pulp content may pose difficulties in the distillation process, requiring additional filtration steps.

Future Prospects and Innovations

The future of wiped film distillation in juice concentration looks promising, with ongoing research and technological advancements opening up new possibilities. Innovations in system design and material science are continually improving the efficiency and applicability of this method. For instance, developments in heat transfer materials and wiper design are allowing for even more efficient evaporation, further reducing energy consumption.

Sustainability is another area where future innovations are focused. As the food and beverage industry increasingly shifts towards sustainable practices, wiped film distillation offers a viable path due to its lower energy requirements and potential for integration with renewable energy sources.

Environmental Impact and Sustainability

The environmental considerations of wiped film distillation add another layer to its appeal. Traditional juice concentration methods, with their higher energy demands and potential for nutrient loss, are increasingly scrutinized for their environmental footprint. Wiped film distillation, in contrast, aligns well with the current drive towards more sustainable industrial processes. Its lower energy requirements mean a reduced carbon footprint, and its efficiency translates to less waste and better utilization of raw materials. This aspect is crucial for juice manufacturers looking to meet the growing consumer demand for environmentally responsible products.

The Role of Wiped Film Distillation in Emerging Markets

Emerging markets present a unique opportunity for the application of wiped film distillation. In countries where the juice industry is rapidly growing, this technology offers a way to leapfrog traditional concentration methods, directly adopting a more efficient, quality-preserving approach. This adoption can be particularly beneficial in regions rich in fruits and natural resources, where local industries can capitalize on wiped film distillation to produce high-quality concentrates for both local consumption and export.

Regulatory and Health Aspects

Regulatory compliance is another important consideration in the juice concentration process. Wiped film distillation's ability to maintain the integrity of the juice aligns well with increasingly stringent food safety and quality regulations worldwide. Additionally, the health aspect of juice consumption - particularly the demand for nutrient-rich, natural products - is well-served by this method. The gentle processing conditions help in retaining vital nutrients and antioxidants, making the concentrates not only tastier but also healthier.

Consumer Trends and Market Demand

Consumer preferences are shifting towards natural, minimally processed foods and beverages. This trend significantly impacts the juice market, where consumers are increasingly aware of the processing methods and their effects on the final product's quality and nutritional value. Wiped film distillation, with its ability to produce high-quality, nutrient-rich juice concentrates, aligns perfectly with these consumer trends, offering manufacturers a competitive edge.

Conclusion

Wiped film distillation represents a significant advancement in the field of juice concentration. Its ability to efficiently produce high-quality concentrates while preserving the natural flavors and nutrients of the juice makes it an invaluable tool for the beverage industry. While challenges such as cost and technical complexity exist, the ongoing technological improvements and a strong focus on sustainability suggest that wiped film distillation will continue to play a crucial role in juice processing.

This method not only stands as a testament to the advancements in food processing technology but also aligns with the broader goals of sustainability and efficiency in the industry. As research continues and technology evolves, wiped film distillation is poised to set new standards in juice concentration, offering a blend of quality, efficiency, and sustainability.

Products

Products