With the continuous development of modern chemical production technology, more and more solutions are used in the production process. However, these solutions are often valuable and potentially recyclable. In order to improve production efficiency, reduce costs and reduce environmental pollution, many chemical plants have begun to use thinner recycler machines to recover and reuse these solutions. This article will conduct an in-depth discussion on the thinner recycler machine.

The Principle Of Thinner Recycler Machine

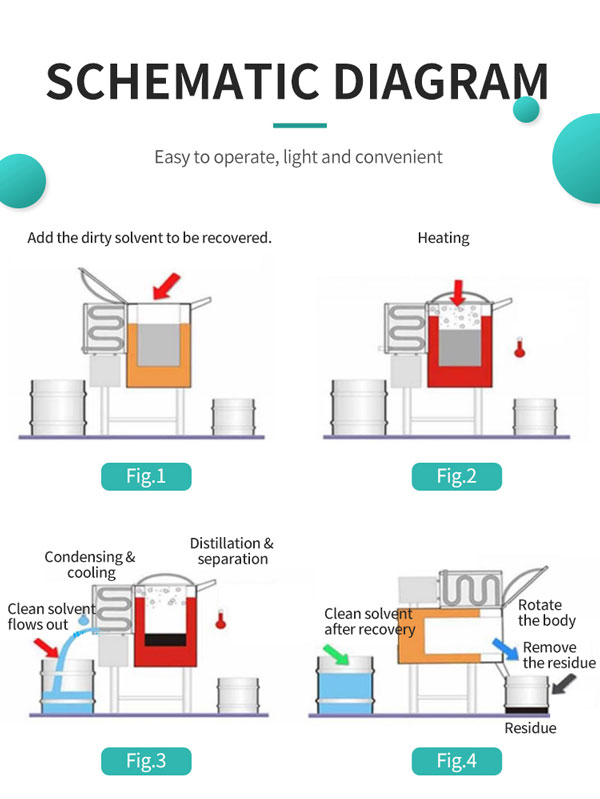

A thinner recycler machine is a device that recycles the solution in wastewater by heating and evaporating. Its main principle is to heat the solution in the wastewater above its boiling point, evaporate the solution into steam, then cool the steam and condense it into liquid, and finally recover the valuable components in it. This technique is called evaporative concentration technique.

In thinner recycler machine, evaporator is the most important part. The evaporator is usually composed of an evaporator body, a heater, a condenser, and a condenser. After the waste water enters the evaporator body, it is heated by the heater and evaporated into steam. The steam then enters the condenser and exchanges heat with cooling water to condense into a liquid. This liquid is called a concentrate. The concentrate then enters the condenser, where it is cooled and condensed to recover its valuable components.

The Value Of Thinner Recycler Machine To The Enterprise

Thinner recycler machine is a very valuable equipment, it can help enterprises realize various values, including cost reduction, efficiency improvement, waste reduction, environmental protection and so on. The following introduces the value of thinner recycler machine to the enterprise respectively.

1. Reduce costs

The thinner recycler machine can recycle valuable solution components, reducing waste generation, and at the same time can reuse the recovered solution, thereby reducing the use of raw materials. In this way, the production cost of the enterprise will be greatly reduced, helping the enterprise to improve its competitiveness and profitability.

2. Improve efficiency

The thinner recycler machine can automate solution recycling and processing without human intervention, thereby increasing production efficiency and output. Through the recycling and processing of thinner recycler machines, enterprises can save time and labor costs, speed up production efficiency, and meet market demand.

3. Reduce waste discharge

Wastewater discharge is an inevitable product in the production process of enterprises, but these wastewaters usually contain a large amount of organic matter and chemicals, which are harmful to the environment and human health. The thinner recycler machine can recycle these valuable components and reduce waste water discharge, thereby mitigating the negative impact of the business on the environment.

4. Protect the environment

With the improvement of environmental protection awareness, it is more and more important for enterprises to pay attention to the environment and sense of responsibility. The thinner recycler machine can recycle useful components in wastewater, thereby reducing pollution and damage to the environment. By adopting thinner recycler machine, enterprises can achieve the goal of environmental protection and gain social and public recognition and praise.

Application Of Thinner Recycler Machine

1. Automobile manufacturing and repair industry:

Cleaning thinner for vehicle spraying equipment pipelines and spray guns, such as thinner, toluene, xylene, methyl ethyl ketone, butyl ester, etc.; solvents produced in the process of cleaning engine gasoline, etc.

2. Electronic product manufacturing industry (such as: LCD, LED, etc.):

Cleaning agents for cleaning molds and cleaning electronic products, such as: absolute ethanol, acetone, trichlorethylene, etc.

3. Precision instrument and hardware manufacturing industry:

Organic solvents for cleaning molds and processed products, such as thinner, hydrocarbons, kerosene, solvent gasoline, etc.

4. Sports equipment manufacturing industry:

Cleaning agents for wax-melted castings such as golf heads and fishing rods, and solvents for spraying and cleaning clubs and fishing rods.

5. Shoe material industry:

Various organic solvents for cleaning spraying equipment, such as: shoe outsole, heel spraying, shoe upper printing processing cleaning, etc.

6. Plastic products:

Organic solvents for cleaning molds and processed products, such as solvents for printing cleaning.

7. Printing industry:

Cleaning agent for cleaning printing plates and machines, such as board washing water, car washing water, etc.

Application Cases Of Thinner Recycler Machine:

1. Chemical enterprises

Chemical enterprises produce a large amount of wastewater in the production process, which contains various organic substances and chemicals, which are harmful to the environment and human health. The use of thinner recycler machine can recycle useful components in wastewater, reduce wastewater discharge, reduce raw material costs, and improve production efficiency and product quality. For example, after a chemical company adopted a thinner recycler machine, the wastewater treatment volume was reduced by 30%, the production cost was reduced by 20%, and the production efficiency and product quality were significantly improved.

2. Semiconductor companies

Semiconductor companies need to use a large amount of chemical solutions in the production process, and these solutions often have high cost and difficult recycling and disposal requirements. For example, after a semiconductor company uses a thinner recycler machine, the yield has increased by 10%, the cost of raw materials has been reduced by 15%, and the production efficiency has also been significantly improved.

3. Metallurgical enterprises

Metallurgical enterprises need to use a large amount of acid-base solutions in the production process. These solutions often contain high concentrations of organic matter and metal ions, which are difficult to recycle and treat. For example, after using a thinner recycler machine in a metallurgical enterprise, wastewater discharge was reduced by 20%, production efficiency increased by 15%, and environmental and health issues were effectively resolved.

4. Textile enterprises

Textile enterprises need to use a large amount of dyes and chemicals in the production process. These substances are high in waste water and have a great impact on the environment. For example, after using the thinner recycler machine in textile enterprises, waste water discharge has been reduced by 40%, raw material costs have been reduced by 25%, and production efficiency and product quality have been significantly improved.

5. Printing companies

Printing companies need to use a lot of chemical solvents and inks in the production process. These substances are high in waste water and difficult to recycle and treat. For example, after a printing company uses a thinner recycler machine, its waste water discharge has been reduced by 30%, raw material costs have been reduced by 20%, and production efficiency and product quality have been significantly improved.

6. Pharmaceutical companies

Pharmaceutical companies need to use a large amount of chemicals and organic substances in the production process. These substances are high in waste water and cause harm to the environment and human health. For example, after using a thinner recycler machine, a pharmaceutical company has reduced wastewater discharge by 25%, reduced raw material costs by 15%, and significantly improved production efficiency and product quality.

Products

Products