Solvent recovery systems are becoming increasingly popular in industries where solvents are used in production processes.

Solvent recovery machine help recover and reuse solvents that would otherwise be wasted, leading to significant cost savings and reduced environmental impact. This article will explore the principles of solvent recovery systems and discuss their various applications in industry.

Principle of Solvent Recovery Systems:

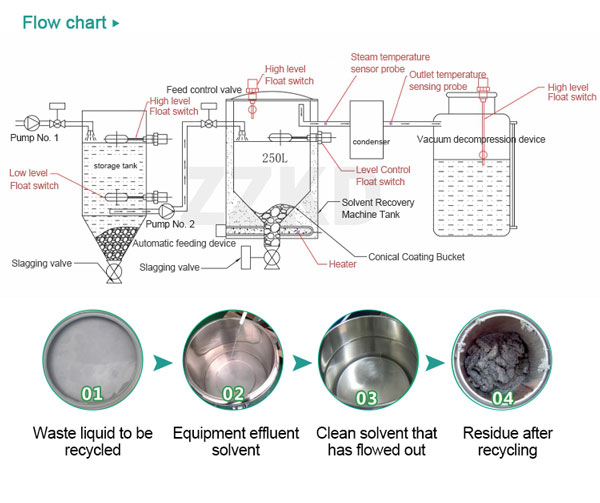

The principle of solvent recovery systems is based on the separation of solvents from other substances in a mixture. Solvents can be recovered through a process called distillation, which involves heating the mixture to produce vapor. The vapor then condenses back into a liquid, leaving behind a concentrated solution of the desired solvent.

The distillation process can be carried out using different types of equipment, including single-stage and multi-stage distillation systems, membrane-based systems,and adsorption-based systems.

Single-stage distillation systems are the simplest and most common type of solvent recovery system. They consist of a distillation column, a reboiler, and a condenser. The reboiler heats the mixture to produce vapor, which rises up the column and is condensed by the condenser. The condensed liquid is then collected and separated into its constituent parts, with the solvent being the desired product.

Multi-stage distillation systems, on the other hand, use multiple distillation columns to separate different solvents from a mixture. The system works by feeding the mixture into the first column, which separates the most volatile solvent. The remaining mixture is then fed into the second column, which separates the next most volatile solvent. This process is repeated for each solvent until all of the solvents have been separated.

Membrane-based solvent recovery systems use permeable membranes to separate solvents from other substances in a mixture. The system works by passing the mixture through the membrane, which allows the solvent to pass through while retaining the other substances. The solvent can then be collected and reused.

Adsorption-based solvent recovery systems use adsorbents such as activated carbon to separate solvents from other substances in a mixture. The system works by passing the mixture through the adsorbent, which adsorbs the solvent. The solvent can then be desorbed from the adsorbent and collected for reuse.

Applications of Solvent Recovery Systems:

Solvent recovery systems have various applications in industries where solvents are used in production processes. Some of the most common applications of solvent recovery systems are discussed below:

1.Pharmaceutical Industry:

The pharmaceutical industry uses solvents in the production of drugs, and solvent recovery systems are commonly used to recover and reuse these solvents. Solvent recovery systems are particularly useful in the production of high-value drugs, where the cost savings from solvent recovery can be significant.

2.Paint and Coatings Industry:

The paint and coatings industry uses solvents in the production of paints and coatings. Solvent recovery systems are used to recover and reuse solvents such as acetone, ethyl acetate, and toluene, which are commonly used in paint and coatings production. The use of solvent recovery systems in this industry can lead to significant cost savings and reduced environmental impact.

3.Chemical Industry:

The chemical industry uses solvents in the production of a wide range of chemicals. Solvent recovery systems are used to recover and reuse solvents in this industry, leading to significant cost savings and reduced environmental impact. Solvent recovery systems are particularly useful in the production of high-value chemicals, where the cost savings from solvent recovery can be significant.

4.Electronics Industry:

The electronics industry uses solvents in the production of electronic components. Solvent recovery systems are used to recover and reuse solvents such as isopropyl alcohol and acetone, which are commonly used in the production of electronic components. The use of solvent recovery systems in this industry can lead to significant cost savings and reduced environmental impact.

5.Printing Industry:

The printing industry uses solvents in the production of printing inks. Solvent recovery systems are used to recover and reuse solvents such as ethyl acetate, toluene, and butyl acetate, which are commonly used in printing ink production. The use of solvent recovery systems in this industry can lead to significant cost savings and reduced environmental impact.

6.Food Industry:

The food industry uses solvents in the production of food ingredients such as flavors and extracts. Solvent recovery systems are used to recover and reuse solvents such as ethanol, which is commonly used in flavor and extract production. The use of solvent recovery systems in this industry can lead to significant cost savings and reduced environmental impact.

Benefits of Solvent Recovery Systems:

The use of solvent recovery systems offers various benefits, including:

Cost savings:

Solvent recovery systems can significantly reduce the cost of purchasing new solvents, leading to cost savings for companies.

Environmental benefits:

Solvent recovery systems can significantly reduce the environmental impact of solvent use, by reducing the amount of solvent waste produced.

Improved efficiency:

Solvent recovery systems can improve production efficiency by allowing for the reuse of solvents, leading to reduced downtime for solvent replacement.

Compliance with regulations:

The use of solvent recovery systems can help companies comply with regulations related to solvent use and waste disposal.

Challenges of Solvent Recovery Systems:

While solvent recovery systems offer various benefits, they also pose some challenges, including:

High initial cost:

Solvent recovery systems can be expensive to install and operate, which can make them less accessible for smaller companies.

Maintenance requirements:

Solvent recovery systems require regular maintenance to ensure they are functioning properly.

Limitations in recovery rates:

Solvent recovery systems may not be able to recover all of the solvent in a mixture, leading to some solvent waste.

Products

Products