Solvent recovery equipment is essential in many industrial processes where solvents are used. Solvents are chemicals that are used to dissolve, dilute or suspend other substances. They are used in a variety of industries such as pharmaceutical, chemical, and automotive, among others. Solvents are usually expensive, and the cost of disposing of them can be significant. Therefore, recovering solvents using solvent recovery equipment is an economical and environmentally friendly solution.

Features of Solvent Recovery Equipment

1. Electric control box: Explosion-proof solvent recovery equipment, sealed to prevent sparks and solvent contact. (Exd II BT6)

2. Controller:

a.32-stage PID temperature and time setting. Color display digital control external device. It can prevent foaming, the recovery flow rate is stable, and the efficiency is high; it can be recovered according to the solvent composition.

b. Timed shutdown can reserve the solvent content to effectively prevent the occurrence of silver powder gas explosion.

c. Ultra-high temperature protection, when the set heating temperature is exceeded, the heating system can be automatically turned off, and the condensation system

3. Bucket tank: solvent recovery equipment is made of imported SS304 stainless steel, the wall of the barrel is thick, and it has a large bearing capacity.

4. Condenser tube: Thick copper tube, anti-corrosion, solvent-resistant; high heat transfer efficiency.

5. Condensing system: solvent recovery equipment equipped with explosion-proof motor; axial fan. (Exd II BT4)

6. Heating system: The heating joint is fully sealed and explosion-proof design.

7. Safety pressure relief system: steel spherical safety valve, solvent-resistant, corrosion-resistant, high-temperature resistant, safe and reliable.

8. Safe dumping system: solvent recovery equipment is easy to operate, light and convenient, can reduce the work intensity of the operator, and is safe and reliable.

9. Won the national explosion-proof certification, EU CE certification and Ping An insurance company underwriting.

Applications of Solvent Recovery Equipment

Solvent recovery equipment is used in a wide range of industries to recover solvents from various sources. The following are some of the most common applications of solvent recovery equipment:

Pharmaceutical Industry

The pharmaceutical industry uses solvents for a variety of purposes such as extraction, purification, and synthesis. Solvent recovery equipment is used to recover solvents from waste streams and cleaning processes. The recovered solvents can be reused, reducing the cost of solvent purchase and waste disposal.

Chemical Industry

The chemical industry uses solvents for various processes such as cleaning, extraction, and reaction. Solvent recovery equipment is used to recover solvents from waste streams and process streams. The recovered solvents can be reused, reducing the cost of solvent purchase and waste disposal.

Automotive Industry

The automotive industry uses solvents for cleaning and degreasing parts. Solvent recovery equipment is used to recover solvents from waste streams and cleaning processes. The recovered solvents can be reused, reducing the cost of solvent purchase and waste disposal.

Paint and Coating Industry

The paint and coating industry uses solvents as carriers and thinners. Solvent recovery equipment is used to recover solvents from waste streams and cleaning processes. The recovered solvents can be reused, reducing the cost of solvent purchase and waste disposal.

Aerospace Industry

The aerospace industry uses solvents for cleaning and degreasing parts. Solvent recovery equipment is used to recover solvents from waste streams and cleaning processes. The recovered solvents can be reused, reducing the cost of solvent purchase and waste disposal.

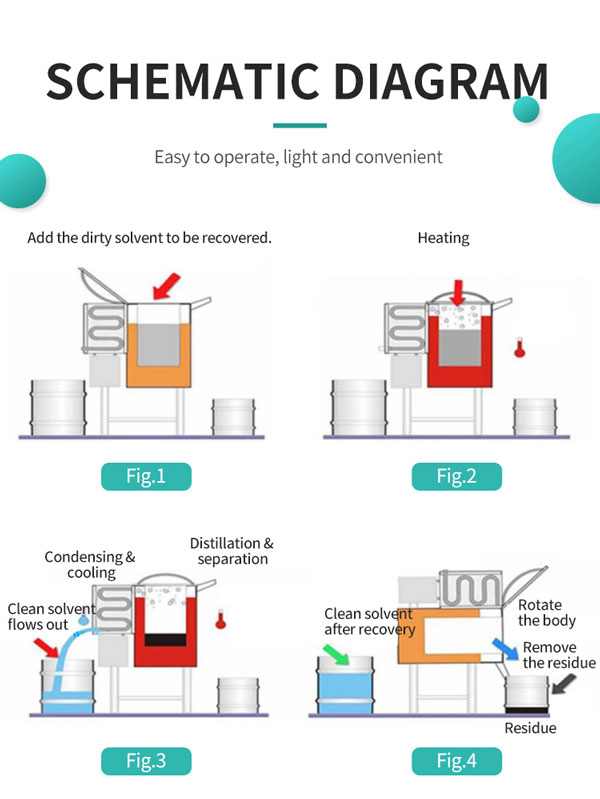

How Solvent Recovery Equipment Works

According to the different boiling points of solvents, heating, distillation, cooling, recycling to clean organic solvents

1. Add the solution to be treated in the container.

2. The heating rod heats the heat medium oil in the interlayer of the recovery barrel.

3. The heat medium oil transfers heat to the waste solution in the recovery bucket to raise the temperature of the solution, and the organic solvent is converted from liquid to gas after being heated.

4. The gaseous solvent is liquefied and flows out through the cooling system; the separated clean solvent flows into the recovery vessel.

5. Clean up the residue after the heat medium oil is cooled.

Benefits of Solvent Recovery Equipment

The use of solvent recovery equipment offers several benefits to industries that use solvents. These benefits include:

Cost Savings

Solvent recovery equipment enables the recovery and reuse of solvents, which reduces the cost of solvent purchase and waste disposal. The recovered solvents can be used again in production processes, reducing the need for new solvent purchases.

Environmental Benefits

Solvent recovery equipment reduces the amount of solvent waste that is discharged into the environment, which helps to reduce pollution. Recovered solvents can be reused, reducing the need for new solvent production, which also helps to reduce environmental impact.

Improved Production Efficiency

Solvent recovery equipment can improve production efficiency by reducing the downtime associated with replacing spent solvents. The recovered solvents can be used again in production processes, reducing the need for new solvent purchases and reducing production downtime.

Compliance with Regulations

Many industries are subject to regulations that limit the amount of solvent waste that can be discharged into the environment. The use of solvent recovery equipment helps industries to comply with these regulations, reducing the risk of fines and penalties.

Solvent recovery equipment is an essential component in many industries that use solvents. The equipment enables the recovery and reuse of solvents, which reduces the cost of solvent purchase and waste disposal, reduces environmental impact, improves production efficiency, and helps industries comply with regulations. There are several types of solvent recovery equipment available in the market, and the type used depends on the type of solvent and the application. It is important for industries to carefully evaluate their solvent recovery needs and choose the appropriate equipment for their specific requirements.

Products

Products