What is a 50L Rotary Evaporator?

A 50L

rotary vacuum evaporator is a laboratory instrument used for removing solvents from samples through evaporation. It is named after its capacity to hold up to 50 liters of material, making it one of the largest and most powerful rotary evaporator models available. The device consists of a water bath, a rotating flask with a sample, and a condenser that helps to cool and condense the evaporated solvent. The sample is rotated and heated under vacuum, allowing the solvent to evaporate and be collected in a separate flask.

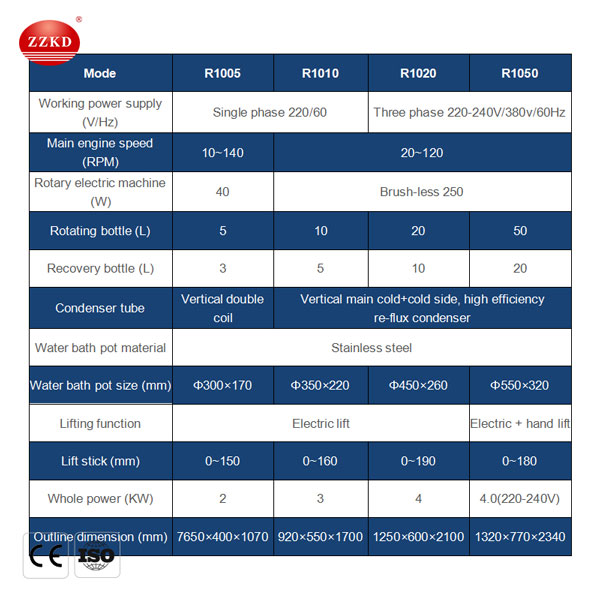

50L Rotary Evaporator Specifications

Working power supply (V/Hz):Three phase 220-240V/380v/60Hz

Main engine speed (RPM):20~120

Rotary electric machine (W):Brush-less 250

Rotating bottle (L):50

Recovery bottle (L):20

Condenser tube:Vertical main cold+cold side, high efficiency re-flux condenser

Water bath pot material:Stainless steel

Water bath pot size (mm):Φ550×320

Lifting function:Electric + hand lift

Lift stick (mm):0~180

Whole power (KW):4.0(220-240V)

Outline dimension (mm):1320×770×2340

Application Case of 50L Rotary Evaporator

Pharmaceutical Industry

In the pharmaceutical sector, the 50L rotary evaporator can be used to increase efficiency in the production of medicines by concentrating and purifying active pharmaceutical ingredients (APIs) and reducing the amount of solvent needed in the manufacturing process.

For example, a pharmaceutical company may have a large quantity of a compound dissolved in a solvent that needs to be concentrated and purified before it can be used as an API. Using a 50L rotary evaporator, the company can quickly and efficiently remove the solvent from the solution, leaving behind a concentrated product that can be further purified or used directly as an API.

Compared to other methods of solvent removal, such as freeze-drying or evaporation under atmospheric pressure, the 50L rotary evaporator is faster and more efficient, allowing pharmaceutical companies to process larger volumes of material in a shorter amount of time. In addition, the rotary evaporator can be easily integrated into existing manufacturing processes, reducing the overall time and cost required to produce pharmaceuticals.

Chemical industry

In the chemical field, the 50L rotary evaporator can be used to increase efficiency in the purification and separation of chemical compounds. One concrete example is the purification of natural products, such as essential oils, from plant materials.

Many natural products contain a mixture of compounds, and the 50L rotary evaporator can be used to isolate and purify specific compounds from these mixtures. For instance, a chemical company might have a large quantity of essential oil extracted from a plant, which contains a mixture of terpenes and other compounds. Using a 50L rotary evaporator, the company can quickly and efficiently isolate and purify specific terpenes for use in various applications.

Biotechnology

In biotechnology, the 50L rotary evaporator can be used to increase efficiency in the processing and purification of biomolecules, such as proteins and nucleic acids. One concrete example is the concentration and purification of recombinant proteins from cell culture media.

Recombinant proteins are often produced in large quantities using bioreactors, and the proteins need to be concentrated and purified before they can be used in various applications, such as therapeutic drugs or diagnostic tests. Using a 50L rotary evaporator, biotech companies can quickly and efficiently remove the liquid component of the cell culture media, leaving behind a concentrated protein solution that can be further purified using other methods.

Advantages of the 50L Rotary Evaporator

The 50L rotary evaporator can help reduce costs and increase productivity in a laboratory setting in several ways:

1.Faster processing:

The 50L rotary evaporator can process larger volumes of material more quickly than other methods of solvent removal and concentration. This helps to increase productivity and reduce processing time, allowing laboratories to process more samples in less time.

2.Efficient solvent recovery:

The 50L rotary evaporator can recover solvents and other organic components from samples, reducing the need for new solvent purchases and minimizing waste. This helps to reduce costs associated with solvent purchase and disposal.

3.Low solvent consumption:

The 50L rotary evaporator requires less solvent than other methods of solvent removal, making it more cost-effective and environmentally friendly.

4.Precise temperature control:

The 50L rotary evaporator has precise temperature control, which helps to preserve the integrity of the sample and improve the quality of the final product. This reduces the need for rework and repeat experiments, saving time and reducing costs.

5.Versatility:

The 50L rotary evaporator can be used for a variety of applications, including concentration of solutions, purification of compounds, and solvent recovery, making it a valuable tool for many laboratory settings. This versatility reduces the need for multiple pieces of equipment, saving money and space.

6.Scalability:

The 50L rotary evaporator is easily scalable, allowing laboratories to process larger or smaller batches of material as needed. This flexibility can help to reduce costs associated with equipment purchases and maintenance.

The 50L Rotary Evaporator is a powerful tool that offers numerous benefits and advantages to a laboratory setting. From rapidly processing large volumes of material to increasing efficiency and productivity, the model has become an indispensable asset for many industries and applications. By understanding its features and considerations, labs can maximize the potential of their 50L rotary evaporator and improve their processes and results.

Products

Products