1. Introduction

The Environmental Hazard of Waste Paint

Waste paint poses significant environmental risks, primarily due to its composition and improper disposal methods. Most paints contain harmful chemicals such as volatile organic compounds (VOCs), heavy metals (like lead and mercury), and other toxic substances. When disposed of improperly, these chemicals can leach into soil and groundwater, causing contamination. This contamination can harm plant and animal life, disrupt ecosystems, and potentially enter the human food chain. Furthermore, VOCs released from paint can contribute to air pollution and smog, exacerbating respiratory problems in humans and animals. Minimizing paint waste and ensuring proper disposal are essential to mitigate these environmental impacts.

The Significance of Waste Paint Recycling

Recycling waste paint is crucial for environmental conservation. By reprocessing leftover paint, we significantly reduce the harmful impacts on ecosystems. This process prevents toxic substances from entering landfills, where they risk contaminating soil and groundwater. Moreover, recycling paint minimizes the need for raw materials, thereby conserving resources and reducing the carbon footprint associated with paint production. This eco-friendly approach also lessens the burden on waste management systems, contributing to a cleaner, more sustainable environment.

Economically, waste paint recycling offers tangible benefits. It fosters a circular economy, where recycled products generate revenue and create job opportunities in the recycling sector. This approach reduces the costs associated with hazardous waste disposal and the environmental remediation of contaminated sites. Furthermore, recycled paint often provides a cost-effective alternative for consumers, promoting sustainable consumption. By embracing paint recycling, businesses and consumers alike contribute to a more resilient and environmentally conscious economy.

2. Classification and Composition of Waste Paint

Understanding Waste Paint Components

Waste paint is composed of several key components, each contributing to its properties and potential environmental impact. The primary component is the pigment, which provides color and opacity. These pigments can be either organic or inorganic, with some containing heavy metals like lead or chromium, posing environmental and health risks. The binder, usually a polymer, holds the pigment particles together and adheres them to the painted surface. Solvents, either water or organic compounds, keep the paint in liquid form for application but evaporate as the paint dries, potentially releasing volatile organic compounds (VOCs) into the atmosphere.

Additionally, waste paint may contain various additives to enhance certain properties, such as drying time, texture, and durability. These additives can include plasticizers, biocides to prevent mold growth, and stabilizers. Over time, some of these chemicals can degrade or leach out, especially if the paint is improperly disposed of. The environmental concern arises from the potential release of these chemicals into the soil and waterways, and the emission of VOCs, which contribute to air pollution and smog. Proper disposal and recycling of waste paint are therefore crucial to mitigate these environmental risks.

Types of Paints: Water-based and Oil-based

Waste paint is composed of several key components, each contributing to its properties and potential environmental impact. The primary component is the pigment, which provides color and opacity. These pigments can be either organic or inorganic, with some containing heavy metals like lead or chromium, posing environmental and health risks. The binder, usually a polymer, holds the pigment particles together and adheres them to the painted surface. Solvents, either water or organic compounds, keep the paint in liquid form for application but evaporate as the paint dries, potentially releasing volatile organic compounds (VOCs) into the atmosphere.

Additionally, waste paint may contain various additives to enhance certain properties, such as drying time, texture, and durability. These additives can include plasticizers, biocides to prevent mold growth, and stabilizers. Over time, some of these chemicals can degrade or leach out, especially if the paint is improperly disposed of. The environmental concern arises from the potential release of these chemicals into the soil and waterways, and the emission of VOCs, which contribute to air pollution and smog. Proper disposal and recycling of waste paint are therefore crucial to mitigate these environmental risks.

3. Environmental Impact of Waste Paint

Soil and Water Contamination Risks

Unprocessed waste paint severely impacts soil quality, primarily due to its toxic constituents. When waste paint seeps into the ground, heavy metals like lead, mercury, and chromium, along with other hazardous chemicals present in the paint, can leach into the soil. This contamination disrupts the natural soil composition and fertility, affecting plant growth and soil microorganisms vital for ecological balance. The presence of these toxins in soil also poses a significant risk of entering the food chain, affecting both wildlife and human health. The long-term accumulation of these chemicals in the soil can lead to irreversible environmental damage.

The impact of unprocessed waste paint on water quality is equally concerning. When it enters waterways, either through runoff or improper disposal, the harmful substances in the paint dissolve and spread, contaminating water sources. This pollution poses serious threats to aquatic life, disrupting ecosystems and potentially leading to the bioaccumulation of toxins in fish and other aquatic organisms. For humans, this contamination can affect drinking water sources, leading to health hazards. Additionally, the solvents and VOCs in the paint can contribute to water and air pollution, further exacerbating environmental and health issues. Proper disposal and treatment of waste paint are essential to protect water quality and the broader environment.

Air Quality Degradation

Waste paint significantly impacts air quality, primarily due to the emission of volatile organic compounds (VOCs) and other hazardous air pollutants. As paint dries and during the disposal process, VOCs are released into the atmosphere. These compounds contribute to the formation of ground-level ozone and smog, exacerbating air pollution. Prolonged exposure to elevated levels of VOCs and smog can lead to respiratory problems, eye irritation, and other health issues in humans. Moreover, some VOCs are known to have long-term health effects, including organ damage and contribution to chronic respiratory conditions.

Furthermore, the improper incineration or burning of waste paint releases additional pollutants, including particulate matter and toxic fumes. Particulate matter can penetrate deep into the lungs, causing respiratory and cardiovascular issues. The burning of paints, especially those containing heavy metals and other toxic chemicals, can also release dioxins and furans, which are highly toxic and can have severe health impacts even at low concentrations. These emissions not only degrade air quality but also pose a significant public health risk. Thus, managing and minimizing waste paint emissions is crucial for maintaining air quality and protecting public health.

4. Waste Paint Recycling Process

Collection and Sorting of Used Paint

The collection process of waste paint begins with the segregation of paint waste at the source, such as households, construction sites, and commercial establishments. Special collection events, designated drop-off sites, and hazardous waste collection programs are often organized by local authorities or environmental organizations to facilitate this. Paint cans and containers are usually required to be tightly sealed and clearly labeled to prevent spills and aid in the classification process. In some cases, paint is also collected directly from large-scale users or retailers who take back unused or leftover paint.

During the classification process, collected paint is sorted based on its type and composition. Water-based paints are separated from oil-based paints due to their differing disposal and recycling methods. The paint is also assessed for contamination and the presence of hazardous components like lead or mercury. This step is crucial as it determines the appropriate recycling or disposal method. For instance, uncontaminated water-based paint can often be recycled and repurposed, while oil-based paints and those with hazardous components require specialized disposal methods to mitigate environmental and health risks. Accurate classification ensures efficient recycling and minimizes the environmental impact of waste paint.

Pre-Processing Steps

Pre-processing of used paint begins with a thorough cleaning and inspection of the collected paint. This step involves opening the paint containers and removing any debris, dirt, or foreign materials that may have contaminated the paint. Paints that have hardened or dried out completely are separated, as they cannot be processed further. The remaining usable paint is then subjected to a series of filtration processes to remove impurities, such as rust from the paint cans, small lumps of coagulated paint, or any other particulate matter. This filtration ensures the purity of the paint, which is crucial for successful recycling.

The next step involves the consolidation and blending of similar types of paint. During this process, paints are categorized based on their type (water-based or oil-based), color, and finish. Once categorized, compatible paints are mixed together to create a uniform batch. This blending is a critical process as it standardizes the paint for further processing and eventual reuse. The blending also helps in adjusting the consistency and quality of the paint, making it suitable for repurposing. These pre-processing steps are vital in ensuring that the recycled paint meets quality standards and is safe for future use.

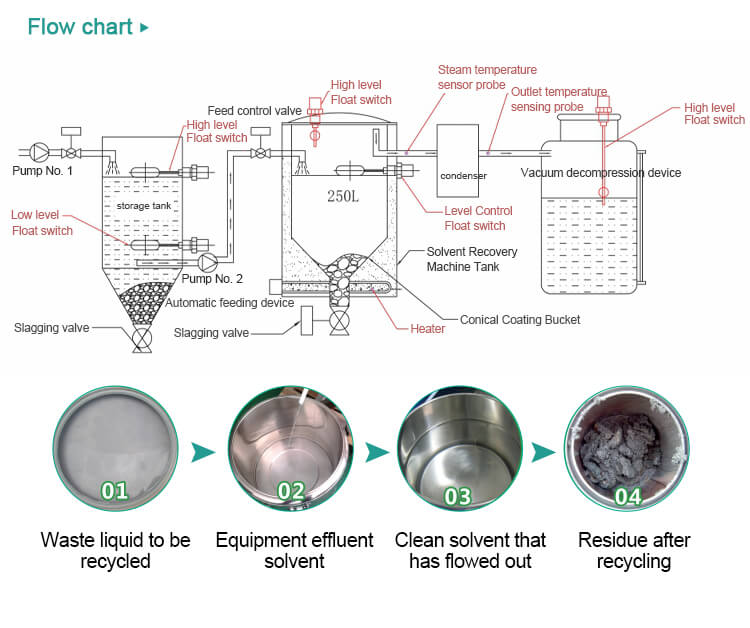

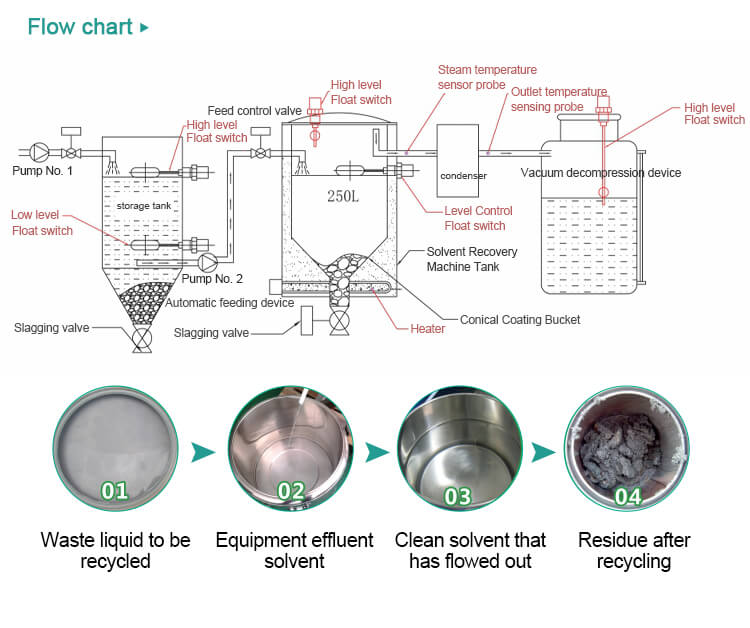

Utilizing Solvent Recovery Machines

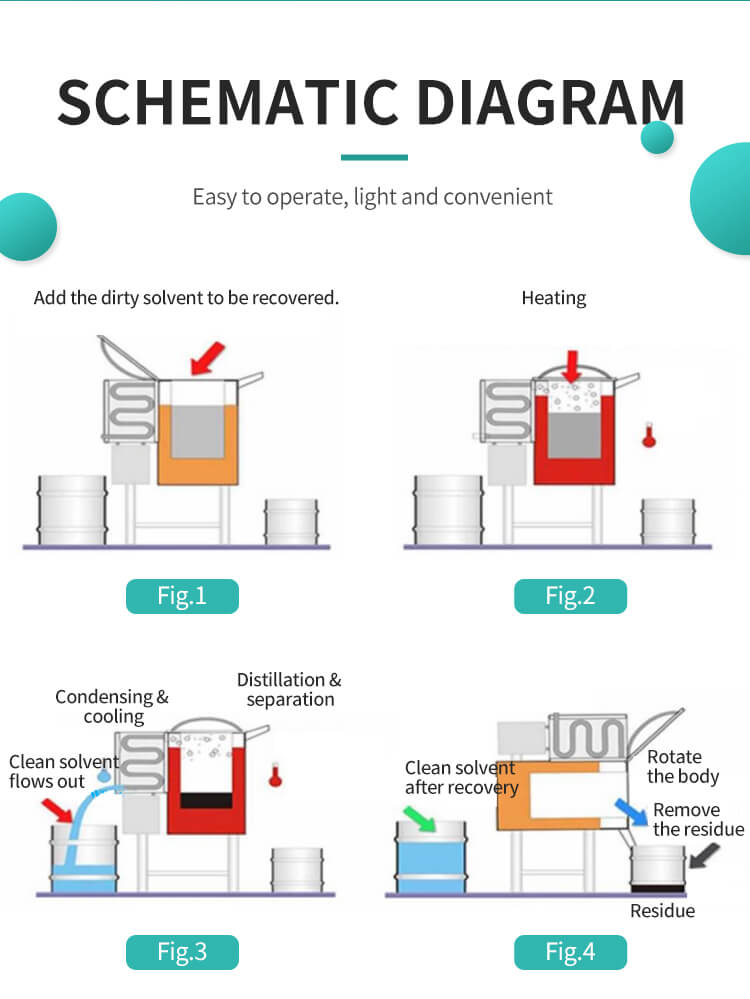

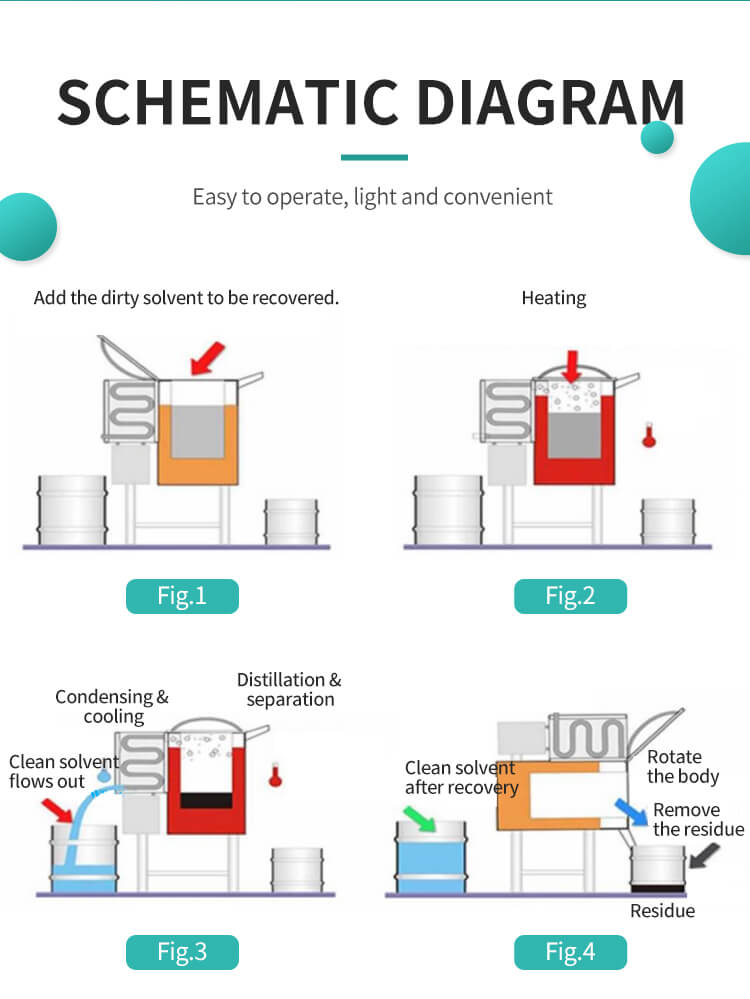

1. Separation Process of Solvents and Waste Paint: The first step involves the separation of solvents from waste paint. In this phase, the waste paint is fed into the solvent recovery machine where it undergoes a distillation process. During distillation, the machine heats the waste paint to a temperature that vaporizes the solvent but not the paint pigments and other non-volatile components. The vaporized solvent is then captured in a condenser, where it cools and returns to a liquid form. This process effectively separates the solvent from the bulk paint material.

2. Purification and Regeneration of Solvents: Once the solvent has been separated, it undergoes further purification to remove any remaining impurities. This step is crucial to ensure that the recovered solvent meets the required standards for reuse. Purification methods can include filtration, additional distillation, or chemical treatments, depending on the type of solvent and the level of purity required. The end result is a regenerated solvent that is almost as good as new, free from contaminants and residues that were present in the original waste paint.

3. Reuse of Purified Solvent: The final step in the process is the reuse of the purified solvent. This regenerated solvent can be used in various applications, including being remixed with new paint, used in industrial cleaning processes, or as a solvent in other chemical processes. By recycling solvents in this way, the need for producing new solvent is reduced, thereby saving resources and reducing environmental impact. The efficiency of the solvent recovery machine in purifying and regenerating solvents makes it a valuable tool in the sustainable management of waste paint, contributing to both environmental protection and economic savings.

5. Technical Details of Solvent Recovery Machines

Working Principle

A solvent recovery machine operates primarily on the principle of distillation, a process that separates different components based on their boiling points. In the context of waste paint, the machine is designed to separate the solvent from the paint mixture. The process begins by heating the waste paint in a closed system. As the temperature rises, the solvent, which typically has a lower boiling point than the other paint components, vaporizes. This vapor, containing the solvent, is then directed into a cooling system.

In the cooling system, the solvent vapor condenses back into liquid form. This phase change is facilitated by a condenser, which cools the vapor, causing it to revert to its liquid state. The recovered liquid solvent is then collected in a separate container, effectively separating it from the non-volatile components of the paint. The purity of the recovered solvent depends on the efficiency of the distillation process and the degree of separation achieved. This process not only recovers valuable solvents for reuse, reducing waste and saving costs, but also minimizes the environmental impact by reducing the need for new solvent production and the safe disposal of hazardous paint waste.

Application in Waste Paint Treatment

Solvent recovery machines are instrumental in the treatment of waste paint, particularly in extracting and recycling solvents, which are a valuable component of many paint formulations. In the context of waste paint, these machines use distillation to separate solvents from the paint mixture. The process involves heating the waste paint to vaporize the solvent, which is then condensed back into a liquid form for collection. This method effectively isolates the solvent, allowing it to be purified and reused. The reuse of these solvents is not only cost-effective but also reduces the environmental impact by decreasing the need for new solvent production and minimizing hazardous waste.

The application of solvent recovery machines extends to various industries where paint is used, including automotive, construction, and manufacturing. The recovered solvents can be reused in paint production or other industrial processes, significantly reducing waste and lowering operational costs. This recycling approach aligns with sustainable practices, reducing the ecological footprint of these industries. By efficiently recovering and reusing solvents, these machines contribute to a circular economy, where resources are conserved, and waste is minimized, marking a significant step towards more environmentally responsible waste paint management.

Efficiency and Economic Analysis

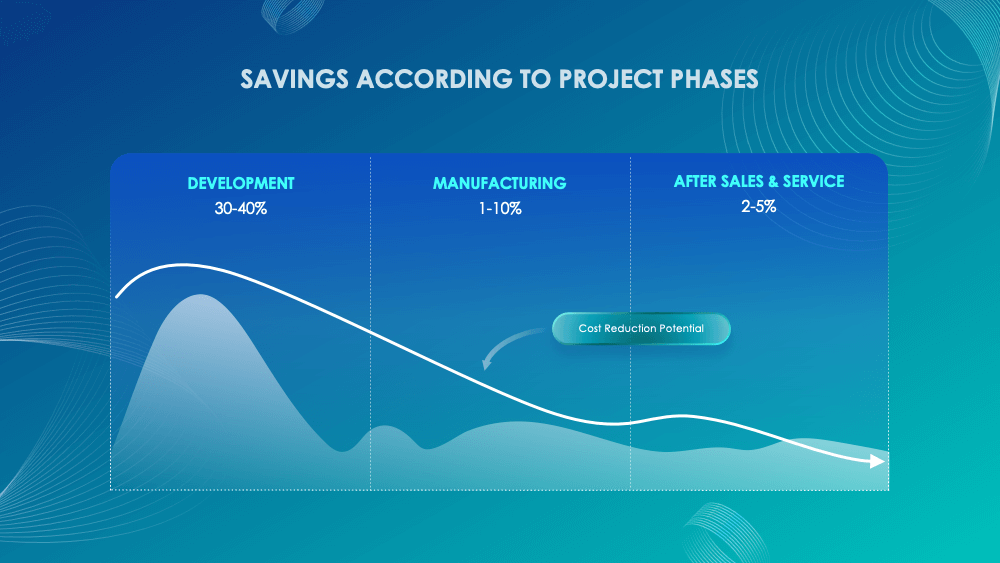

The efficiency of solvent recovery machines is evident in their ability to recover a high percentage of usable solvents from waste paint. These machines operate on advanced distillation principles, ensuring a thorough separation of solvents from paint residues. The process is designed to maximize solvent recovery while maintaining the purity of the reclaimed solvent. This efficiency not only conserves resources but also reduces the environmental burden of paint waste. The ability to recover and reuse solvents means less need for producing new solvents, thereby conserving raw materials and energy typically used in solvent production.

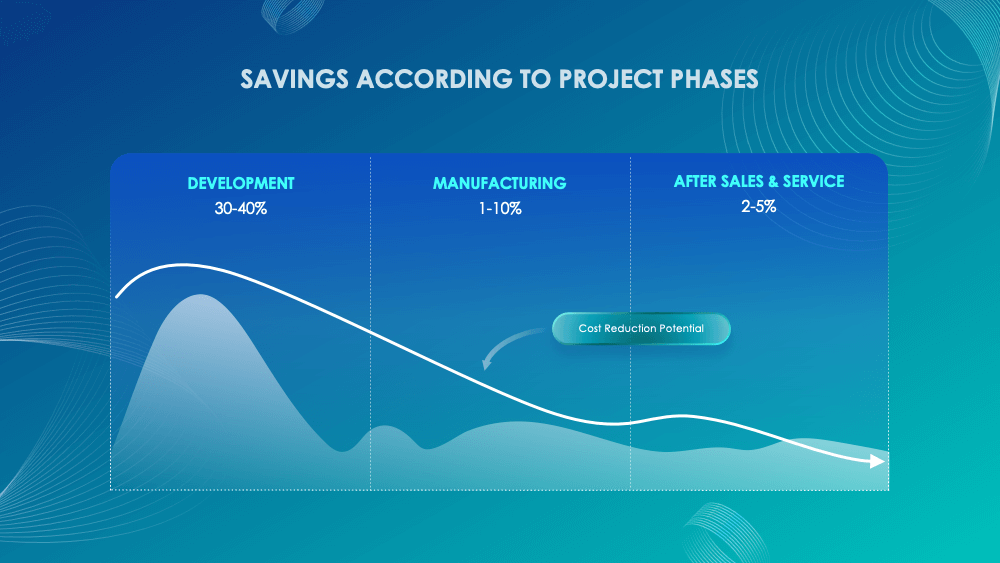

From an economic perspective, solvent recovery machines offer significant cost savings. The initial investment in these machines is offset by the reduction in the cost of purchasing new solvents and the expenses associated with hazardous waste disposal. Industries that utilize these machines can recoup their investment over time through these savings. Additionally, the ability to reclaim and reuse solvents leads to more sustainable operational practices, which can enhance a company's environmental reputation. This aspect is increasingly important in a market where eco-consciousness is a valuable asset. Thus, the adoption of solvent recovery machines is not only an environmentally sound decision but also a financially prudent one for industries dealing with waste paint.

6. Economic Benefits of Waste Paint Recycling

Cost-Benefit Analysis

The cost-benefit ratio of waste paint recycling leans favorably towards benefits, both in environmental and economic terms. The initial costs involved in recycling waste paint include the investment in recycling facilities, machinery like solvent recovery machines, and the labor involved in collection, sorting, and processing. However, these costs are offset by the significant environmental benefits. Recycling paint reduces the amount of hazardous waste entering landfills, minimizes the release of toxic chemicals into the environment, and conserves resources by reducing the need for new raw materials. This positive environmental impact is a crucial benefit, contributing to sustainability and ecological conservation.

Economically, waste paint recycling presents substantial benefits over the long term. The process of recycling generates new products from old paint, such as remanufactured paint or other materials, creating a new revenue stream. Moreover, the recovery and reuse of solvents reduce the need for purchasing new solvents, offering considerable cost savings for industries. Over time, these savings can outweigh the initial investment and operational costs of recycling. Additionally, waste paint recycling can create job opportunities in the recycling sector, contributing to the local economy. Therefore, while the upfront costs of recycling may be significant, the long-term economic and environmental benefits make it a worthwhile endeavor.

Resource Conservation and Disposal Cost Reduction

Recycling offers substantial opportunities for saving resources, primarily by reducing the need for extracting and processing new raw materials. When materials like plastics, metals, paper, and glass are recycled, they are reprocessed into new products, significantly conserving natural resources. For instance, recycling aluminum saves up to 95% of the energy required to produce new aluminum from bauxite ore. Similarly, recycling paper reduces the need for virgin timber. This conservation is crucial for sustainable resource management, as it minimizes environmental degradation and preserves natural habitats. Moreover, recycling helps in reducing greenhouse gas emissions associated with manufacturing processes, contributing to the fight against climate change.

Economically, recycling can lead to substantial reductions in disposal costs. Landfill space is limited and expensive, and the costs are increasing as availability decreases. By diverting materials from landfills through recycling, municipalities and businesses can save on these expenses. Additionally, recycling can generate income through the sale of recyclable materials, providing an additional financial incentive. The recycling industry also creates jobs, supporting local economies. Over time, the cumulative cost savings from reduced raw material consumption, lower disposal fees, and income from recyclable materials can be significant, making recycling not just an environmentally responsible choice but also a financially sound strategy.

Market Value of Solvent Recovery Technologies

The market potential of solvent recovery technology is substantial, particularly in industries where solvents are extensively used, such as pharmaceuticals, chemical manufacturing, painting, and printing. This technology addresses a critical need for sustainable solvent management, offering a practical solution to reduce hazardous waste and environmental pollution. As environmental regulations become stricter and corporate sustainability goals more ambitious, the demand for efficient and eco-friendly solvent recovery systems is expected to grow. Companies are increasingly recognizing the cost benefits of recovering and reusing solvents, which can significantly reduce operational expenses associated with solvent purchasing and hazardous waste disposal.

Moreover, the growing global emphasis on circular economy principles bolsters the market value of solvent recovery technology. By enabling the reuse of solvents, this technology contributes to resource efficiency and waste minimization, aligning with the broader sustainability trends in various sectors. This alignment is likely to attract investment and foster technological advancements in solvent recovery systems, further enhancing their efficiency and appeal to a wider range of industries. Additionally, as consumer awareness and preference for environmentally responsible practices increase, businesses adopting solvent recovery technologies can leverage this to enhance their brand image and competitive edge in the market. This market dynamic positions solvent recovery technology not just as an environmental imperative but also as a strategic business asset.

7. Market Prospects and Potential Opportunities

Future Market Trends

The waste paint recycling market is poised for significant growth, driven by increasing environmental awareness and stricter regulatory frameworks regarding waste management. As governments and international organizations intensify their focus on reducing landfill waste and promoting circular economy models, the recycling of waste paint is becoming a more prominent agenda. This trend is likely to result in more robust and widespread recycling programs, coupled with incentives for businesses and consumers to participate in paint recycling initiatives. Additionally, technological advancements in recycling processes are expected to improve the efficiency and cost-effectiveness of paint recycling, making it more accessible and appealing.

The market is also likely to see an expansion in the range of recycled paint products. Innovations in recycling technology may enable the extraction and reuse of more complex paint components, leading to higher quality recycled paint products and potentially new uses for recycled paint materials in other industries. As consumer attitudes continue to shift towards more sustainable products, the demand for recycled paint and related eco-friendly products is expected to rise. This growing market demand, alongside technological and regulatory developments, suggests a vibrant and evolving future for the waste paint recycling industry.

Impact of Emerging Technologies

Emerging technologies and innovations are set to revolutionize the scrap paint recycling market, enhancing both efficiency and effectiveness. Advanced sorting and processing technologies, such as AI-driven automation and sophisticated chemical analysis methods, are improving the accuracy and speed of separating and recycling different components of paint. These advancements facilitate the recovery of higher quality materials and reduce processing costs. Additionally, breakthroughs in chemical recycling technologies are enabling the conversion of scrap paint into valuable raw materials, which can be reused in various industrial applications, expanding the scope of recycling beyond traditional methods.

The integration of digital technologies like IoT and blockchain is also transforming the scrap paint recycling market. IoT devices can track and optimize the collection and transportation of scrap paint, leading to more efficient recycling operations. Blockchain technology offers transparency and traceability in the recycling process, ensuring compliance with environmental regulations and enhancing consumer confidence in recycled products. These innovations not only streamline the recycling process but also open up new market opportunities by creating a more sustainable and circular economy for paint products. As these technologies continue to evolve, they will undoubtedly shape the future landscape of the scrap paint recycling market.

Regulatory Influence on Market Development

Policies and regulations play a pivotal role in shaping the used paint recycling market. Stringent environmental regulations and policies that mandate recycling and proper disposal of hazardous waste, including used paint, significantly drive the growth of this market. Such regulations often come with penalties for non-compliance, incentivizing industries and consumers to opt for recycling. Furthermore, government initiatives like subsidies, tax incentives, or grants for recycling projects encourage investment in recycling infrastructure and technology. These policies create a conducive environment for the growth of the recycling market, ensuring a steady supply of recyclables and promoting sustainable practices.

Conversely, the absence of robust regulations or weak enforcement can hinder the development of the used paint recycling market. In regions where regulations are lax, there's less motivation for businesses and consumers to recycle, leading to higher rates of improper disposal and environmental damage. However, the increasing global focus on sustainability and circular economy concepts is likely to influence policy development towards more stringent recycling mandates. As awareness of environmental issues grows, public demand for responsible waste management is expected to increase, potentially leading to stricter regulations and greater support for the recycling market, including the sector dealing with used paint.

8. Waste Paint Solvent Recycling Solution

Case

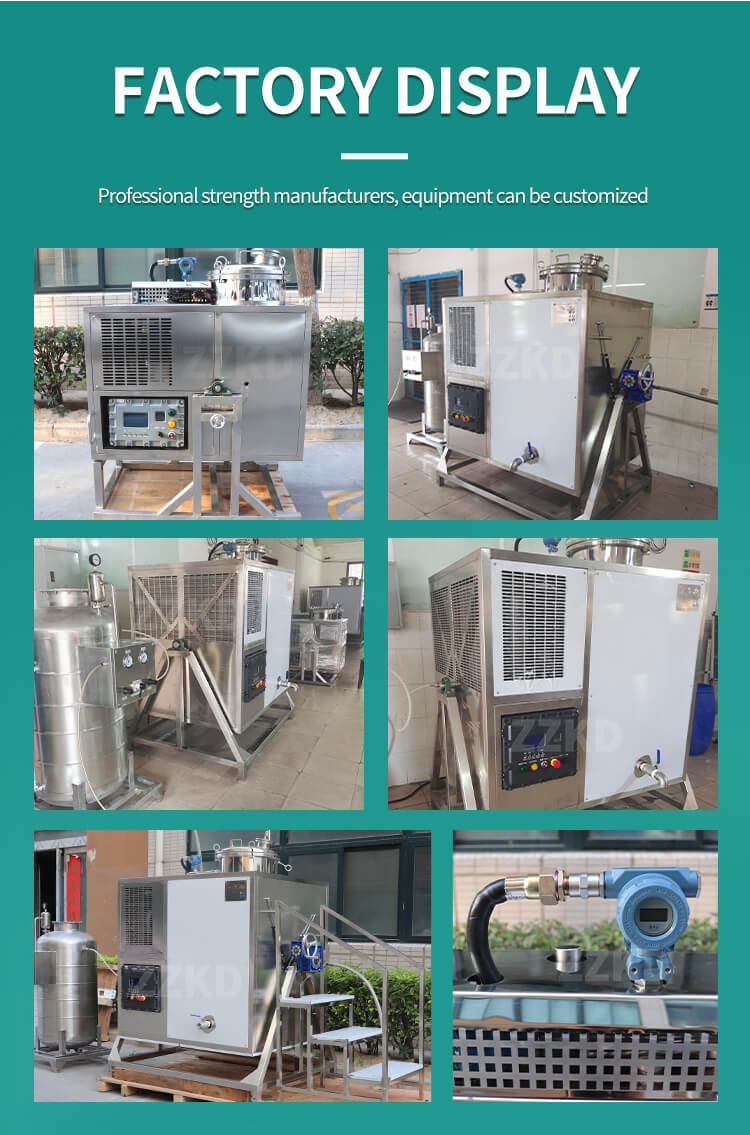

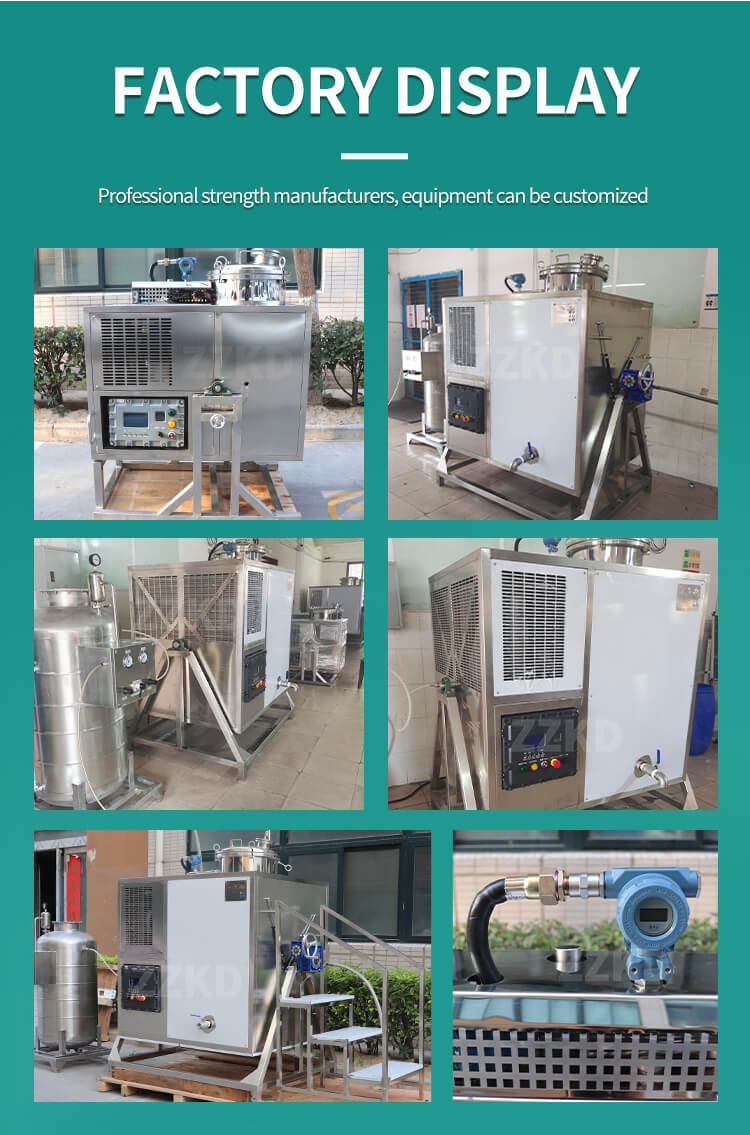

A notable case of waste paint solvent recycling can be seen in a large automotive manufacturing company. Faced with the challenge of disposing significant quantities of waste paint solvents generated from their painting operations, the company implemented an on-site solvent recovery system. This system utilized advanced distillation technology to separate and purify the solvents from the waste paint. The process not only successfully recovered a high percentage of solvents but also maintained their purity, making them suitable for reuse in the painting process. This closed-loop system significantly reduced the company's solvent purchasing costs and minimized its environmental footprint.

The impact of this initiative extended beyond cost savings and environmental benefits. By recycling the solvents, the company reduced its dependence on external solvent suppliers and mitigated the risks associated with volatile solvent market prices. The initiative also aligned with the company's sustainability goals, enhancing its corporate social responsibility profile. The success of this case has served as a model for other companies in the industry, demonstrating the viability and benefits of incorporating solvent recovery systems in paint-related operations. It highlights how waste paint solvent recycling can be both an economically and environmentally sound strategy in industrial settings.

Analysis of Operating Effects and Market Potential

In the mentioned case of the automotive company, the operating effect of the solvent recovery machine was highly positive. The system efficiently processed large volumes of waste paint solvents, showcasing its capability to handle industrial-scale requirements. The high recovery rate of solvents significantly reduced the volume of hazardous waste, exemplifying an effective waste management solution. Moreover, the purity of the recovered solvents ensured they were of sufficient quality for reuse in the company's painting processes, demonstrating the machine's effectiveness in maintaining essential solvent characteristics.

Economically, the solvent recovery machine brought substantial benefits to the company. The reduction in the need to purchase new solvents translated into considerable cost savings, directly impacting the company's bottom line. This cost-effectiveness was a key factor in the machine's return on investment, making it an attractive solution for similar industries. The success in this case also highlights the market potential of solvent recovery machines. As industries increasingly focus on sustainability and cost-efficiency, the demand for such technology is likely to grow. This case exemplifies how solvent recovery can be a financially viable and environmentally responsible choice, positioning it as a valuable tool in the market of industrial waste management solutions.

9. Policies and Regulations

Overview of Recycling Regulations

Policies affecting the recycling of used paint often include regulations that mandate the proper disposal and recycling of hazardous waste, including paint products. These regulations typically require producers and distributors of paint to participate in take-back programs or contribute to recycling efforts. They also set standards for the safe handling, storage, and transportation of hazardous materials, ensuring that paint recycling processes do not pose environmental or health risks.

Moreover, many regions have implemented Extended Producer Responsibility (EPR) laws, which hold paint manufacturers accountable for the end-of-life management of their products. These laws encourage the development of more sustainable paint products and recycling programs. Incentives such as tax breaks or subsidies are also commonly provided to support businesses and consumers who participate in paint recycling initiatives, promoting a culture of sustainability and responsible waste management.

Solvent Recycling Machine for Sale

Policy Impact on Recycling Efficiency

Effective policies can significantly enhance waste paint recycling efficiency by setting clear standards and guidelines for collection, sorting, and processing practices. Regulations that incentivize the establishment of specialized recycling facilities and advanced technologies can lead to more efficient recycling processes, higher recovery rates of valuable materials, and a reduction in environmental pollution. Such policies foster innovation and improvement in recycling methodologies, directly contributing to increased recycling efficiency.

Furthermore, policies like tax incentives, grants, and subsidies for recycling initiatives can stimulate market development. They encourage investment in the recycling sector, attracting new players and fostering competition, which can lead to technological advancements and cost reductions. Additionally, public awareness campaigns and education programs, often part of policy frameworks, can increase participation rates in recycling programs, ensuring a steady supply of recyclable materials and bolstering the market for recycled products. These policy measures collectively create a more vibrant and sustainable waste paint recycling market.

10. Future Prospects

Technological Development Trends

The future of waste paint recycling technology is likely to see significant advancements in automation and efficiency. Innovations in sorting and processing technologies, driven by artificial intelligence and machine learning, are expected to streamline the recycling process. These advancements will enable more precise separation of paint components, enhancing the quality of recycled materials and reducing processing time and costs.

Additionally, there is a growing trend towards sustainable and environmentally friendly recycling methods. Research and development in green chemistry are likely to produce new methods for recycling paint that minimize environmental impact. These innovations could include more effective solvent recovery techniques and the development of biodegradable or less toxic paint formulations, making the recycling process safer and more sustainable.

Innovations in Recycling

Technological innovation holds immense potential to improve recycling efficiency. Advancements in sorting and processing technologies, such as enhanced optical sorting systems and robotic automation, can lead to more accurate and faster separation of recyclable materials. This increased efficiency not only boosts the volume of materials recovered but also enhances the purity and quality of the recycled output, reducing contamination and subsequent processing costs.

Economically, these technological improvements can significantly enhance the cost-effectiveness of recycling operations. By optimizing the recycling process, operational expenses are reduced, and the yield of high-quality recyclable materials is increased. This improvement in yield can lead to higher market values for recycled products, generating greater revenue. Furthermore, innovative technologies can open up new avenues for recycling previously non-recyclable materials, expanding the market and creating new economic opportunities in the recycling industry.

11. Conclusion

Reiterating the Importance of Waste Paint Recycling

Waste paint recycling holds substantial environmental importance as it helps mitigate the harmful effects of improper paint disposal. Recycling reduces the release of toxic chemicals into soil and water bodies, thereby protecting ecosystems and public health. It also lessens the environmental footprint by conserving resources and reducing greenhouse gas emissions associated with the production of new paint.

Economically, waste paint recycling offers significant benefits. It reduces the costs associated with hazardous waste disposal and conserves resources, lowering the demand for new raw materials. Recycling also stimulates market growth in the green sector, creating job opportunities and promoting sustainable industry practices. This contributes to a circular economy, where waste is minimized and resources are efficiently utilized.

The Need for Continued Research and Improvement

Continued research and improvement in waste paint recycling technology are essential to address the growing environmental challenges posed by paint disposal. With the increasing volume of paint waste generated globally, there is a pressing need to develop more efficient and sustainable recycling methods. Innovations in this field can lead to advanced techniques for separating and detoxifying paint components, significantly reducing the environmental impact of paint waste. Enhanced recycling technology can also facilitate the recovery of valuable materials from waste paint, promoting resource conservation and reducing reliance on virgin materials.

Economically, advancements in recycling technology can transform the waste paint industry into a more profitable and sustainable sector. Improved recycling methods can lead to cost reductions in the recycling process, making it more economically viable for companies to invest in recycling facilities. Furthermore, the development of new recycling technologies can create opportunities for innovative products and services, stimulating economic growth in the green sector. This not only contributes to a more circular economy but also positions waste paint recycling as a key player in the global effort towards sustainability and environmental stewardship.

ZZKD Machinery emphasizes the continuous need for research and technological advancements in the field of waste paint recycling. As we face growing environmental challenges, the development of efficient and sustainable recycling methods becomes increasingly vital. Recognizing this, ZZKD Machinery is at the forefront of driving innovations in recycling technology, striving to create solutions that are both environmentally responsible and economically viable. Our commitment to advancing recycling methods showcases our dedication to environmental stewardship and resource conservation.

We invite readers to explore the offerings of ZZKD Machinery and Instrument Equipment Co., Ltd. Our range of advanced recycling solutions reflects our expertise and innovation in the industry. By partnering with us, businesses and organizations can access cutting-edge technologies for waste paint recycling, contributing to a more sustainable future. Our solutions are designed to meet the evolving needs of the recycling sector, ensuring efficiency, effectiveness, and compliance with environmental standards. Join us in our mission to revolutionize waste paint recycling and make a positive impact on our planet.

Products

Products