The lacquer thinner recycler is an environmentally friendly machine. It turns the solvent into a gaseous state by heating and evaporating, and the vapor enters the cooling system to liquefy and flow out. In this way, clean organic solvents are recovered. Solvent recovery machine is mainly used to recycle waste and dirty organic chemical cleaning solvents to achieve recycling. purpose of reuse. It has both economic and environmental significance.

Absolute Money Saving: Significant savings in purchasing new solvents.

Wide range of recovery: many types of organic solvents can be recovered.

Environmental protection significance: waste organic solvents can be regenerated and recycled to reduce the pollution of waste solvents to the environment.

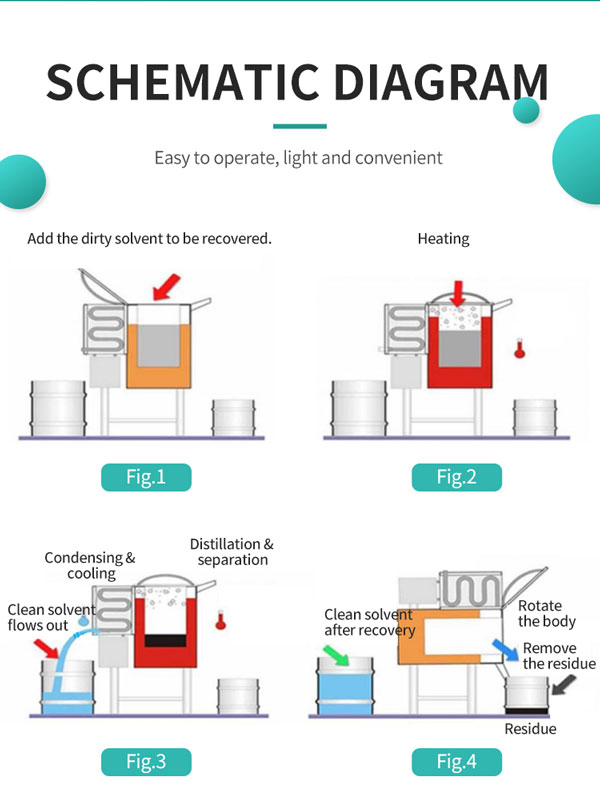

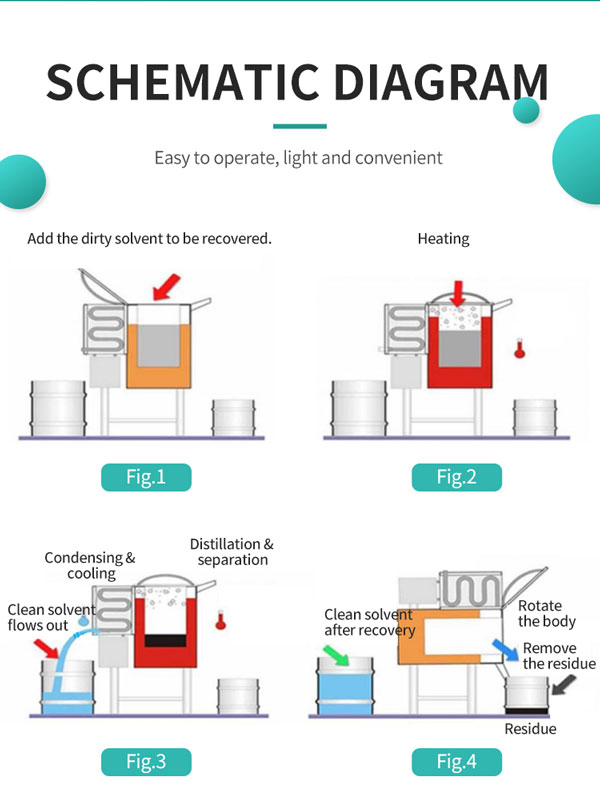

The Recycling Principle Of Lacquer Thinner Recycler:

According to the different boiling points of solvents, heating, distillation, cooling are carried out to recover clean organic solvents.

Add the solution that needs to be recycled;

The heating rod heats the heat medium in the fire layer of the recovery barrel; the heat medium transfers heat to the waste solution in the recovery barrel to heat up the solution, and the organic solvent is converted from a liquid state to a vapor state after being heated;

The vapor solvent is liquefied and flows out through the cooling system; the separated clean solvent flows into the recovery vessel;

Clean up debris.

In this way, through distillation and cooling, clean organic solvents are recovered for use, realizing the purpose of resource recovery and reuse.

How To Choose The Right Lacquer Thinner Recycler Model?

According to 200L of waste solvent, it is recycled 5 times a day, and the T-40Ex solvent recovery machine can meet your waste solvent recovery needs.

1. Operating time: an average of 150 minutes (depending on the type of solvent and the concentration of the solvent)

2. Temperature control: heating temperature setting: 50-240°C, steam temperature setting 0-200°C

3. Air-cooled cooling does not require cooling water

4. Recovery rate: 95% (ratio of recovered solvent amount to solvent content in waste liquid)

5. The recycling tank can be dumped, easy to remove residues

6.Power supply: 380ACV

7. Power: 4kW

Lacquer Thinner Recycler Applicable Industries:

1. Automobile manufacturing and repair industry: cleaning thinner for vehicle spraying equipment pipelines and spray guns, such as thinner, toluene, xylene, methyl ethyl ketone, butyl ester, etc.; solvents produced in the process of cleaning engines such as gasoline.

2. Electronic product manufacturing industry (such as: LCD, LED, etc.): Cleaning agents for cleaning molds and electronic products themselves, such as: absolute ethanol, acetone, trichloroethylene, etc.

3. Precision instrument and hardware manufacturing industry: organic solvents for cleaning molds and processed products, such as thinner, hydrocarbon, kerosene, solvent gasoline, etc.

4. Sports equipment manufacturing industry: cleaning agents for wax-melting castings such as golf heads and fishing rods, and solvents for spraying and cleaning clubs and fishing rods.

5. Shoe material industry: various organic solvents for cleaning and spraying equipment, such as: shoe outsole, heel spraying, shoe upper printing processing cleaning, etc.

6. Plastic products: organic solvents for cleaning molds and processed products, such as: solvents for printing cleaning.

7. Printing industry: Cleaning agents for cleaning plates and machines, such as board washing water, car washing water, etc.

8. Paint manufacturing and chemical industry: various organic solvents and paint mixing agents for cleaning production equipment, containers and filling equipment, such as thinner, xylene, methyl ethyl ketone, butyl ester, etc.

9. Painted gold jewelry industry: solvents used for surface pretreatment cleaning and electroplating pretreatment.

Saving Money Is The Last Word, And It Is Worth Investing In Buying!

The recovery rate is generally as high as 95%, and the average price of organic solvents is also around 10/L.

|

Daily Recovery |

Monthly Recovery |

Annual Recycling |

Annual Savings |

|

9L |

270L |

3200L |

USD 5400 |

|

90L |

2700L |

32000L |

USD 54000 |

|

180L |

5400L |

64000L |

USD 108000 |

Lacquer Thinner Recycler Process Features:

1. The temperature is accurate; the digital setting displays the temperature, and the minimum reading value is 0.1°C

2. The explosion-proof box complies with the Chinese Exde llB T6 explosion-proof standard

3. Automatic shutdown system: it can be controlled by time or temperature

4. The recovery tank can be dumped, easy to remove residues

5. Double-layer stainless steel barrel design, indirect heating, to prevent solvent leakage

6. The switch is made of explosion-proof materials that are not corroded by solvents

7. The heating system and other wires are designed with a fully sealed head

8. The motor is an imported magnetic levitation type, which will not generate electric sparks

9. The temperature display has no contacts and will not generate electric sparks

10. By leaving 3-5% solvent in the machine setting, the safety of the equipment can be ensured and the safety factor can be improved

11. Shut down at a fixed temperature, after the solvent is recovered, it will automatically shut down according to the steam temperature

12. Timing shutdown, according to time, double shutdown protection function

13. Ultra-high temperature protection, when the machine exceeds the set temperature, it will automatically stop the heating system

14. Ultra-high pressure protection, when the air pressure in the tank of the machine exceeds 0.3Br outside, the pressure will be automatically released to ensure the safety of the machine.

Unique Features:

1. The cooling system adopts air cooling to dissipate heat, saving a lot of water resources

2. The unique machine dumping function is convenient for cleaning the recycled residue

3. Unique segmental recovery function to solve the foaming problem of mixed solvents

4. The lacquer thinner recycler is equipped with a corresponding condenser, which can recycle low boiling point solvents at -25°C to 60°C

5. The lacquer thinner recycler is equipped with a corresponding vacuum pump, which can recycle high boiling point solvents below 300°C

6. Unique timing shutdown function, which can avoid silver powder gas explosion after solvent recovery

The company's lacquer thinner recycler technology is mature, and has been running well in many factories around the world, and has been fully recognized by customers. It solves the problem of waste solvent discharge, and also saves a lot of cost for the factory to purchase solvents.

This lacquer thinner recycler adopts high-quality components and materials, and is strictly manufactured to ensure the excellent quality of the machine and ensure that the machine equipment is completely safe and truly practical and effective.

Products

Products