Description

Product Description

TGYF-C desktop high pressure reactor is a simple bottom heating and stirring high pressure reactor produced according to the functional characteristics of high pressure reactor according to customer requirements. Made of stainless steel, the volume can be customized according to customer needs.

The capacity of this series of high pressure reactors is: 50ml, 100ml, 250ml, 500ml for users to choose, the miniature reactor is small in size, and the structure of the whole machine is simple and reliable. Equipped with original German imported miniature DC motor, pressure gauge, explosion-proof device, intake valve, sampling valve, temperature probe as standard, which can facilitate the realization of micro-reaction test

Applications:

The desktop stainless steel reaction kettle is suitable for various reactions such as gas-liquid, liquid-liquid, liquid-solid-gas, etc. This device mainly adopts a static sealing structure, which can completely solve the leakage problem of stirring and make the whole medium and stirring parts completely. Work in an absolutely sealed state. Therefore, it is more suitable for stirring reaction of various flammable, explosive, highly toxic, precious media and other chemical media with strong penetration. This product integrates stirring, heating and reaction, and combines a magnetic stirrer with a stainless steel reaction kettle. The equipment is more versatile and the user costs less. Widely used in colleges and universities, environmental protection, biochemical, medical, scientific research and other fields.

Product Structure And Performance

●Stirring method: Internal magnetic stirring, there is no problem of shaft seal leakage and maintenance, ensuring no leakage, no exposed rotating parts, and the test is safer.

●Mixing motor: high-power brushless motor imported from Germany, powerful and stable in performance.

●Inlet gas valve: gas inlet needle valve.

●Sampling valve: It is convenient to take samples at any time during the reaction and analyze the reaction process.

●Exhaust valve: It is convenient to vacuum the system and replace the gas before the reaction, and it can be used as a vent valve after the reaction.

●Pressure gauge: Real-time monitoring of reaction pressure in the kettle.

●Temperature probe: Go deep into the reactor body to monitor the reaction temperature.

●Heating unit: module heating, fast heating, precise control, digital display on the screen.

Connection method: flange connection.

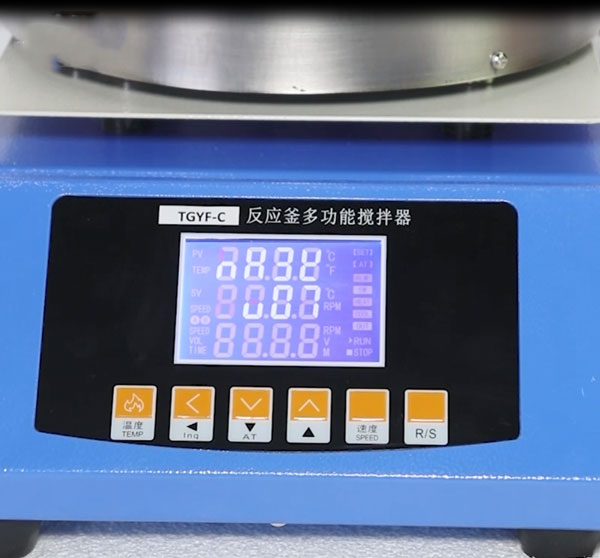

Temperature And Rpm Settings

Temperature settings:

●Click the "Temperature" button to enter the temperature setting state, that is, the upper row of the LCD screen displays the temperature setting prompt "SP", and the lower row displays the temperature setting value.

●The required setting value can be modified by the shift, increase and decrease keys; then click the "temperature" key, the controller will automatically save the temperature and time set values and exit the setting state.

● When the timing time (ST) is set to "0", the continuous operation of the controller will not stop automatically;

● When the set time "ST" is not "0", when the time is up, the LCD screen displays "End" in the lower row, and the buzzer stops after 1 minute.

● After the run is over, click the "Run/Stop" button to restart the run.

Speed setting:

● Click the "Speed" button to enter the speed setting state, the upper row of the LCD screen displays the speed setting prompt "Sd", and the lower row displays the speed setting value

●It can be modified to the required setting value through the shift, increase and decrease keys;

● Click the "Speed" key to exit this setting state, and the setting value is automatically saved.

● Press the R/S start/stop key to start and stop stirring.

Use And Precautions:

1. It is recommended that the heating temperature should not exceed 350°C, the heating rate should be ≤5°Cmin, and the PID temperature control system can be used to control the temperature, and the cooling rate should be ≤5°Cmin. The safety pressure is 22MPa.

2. After feeding, the screws are pressed symmetrically. When the reaction is completed, the lid of the kettle can be opened after the kettle body is naturally cooled to room temperature.

3. When tightening the nut, it must be tightened diagonally symmetrically for several times and gradually tightened with uniform force, and the kettle cover is not allowed to tilt to one side to achieve a good sealing effect; when tightening the main nut, the specified tightening torque should not exceed the range of 40~120nm. In order to prevent the sealing surface from being squeezed or overloaded.

4. The filling degree in the kettle should not exceed 80%.

Products

Products

Get Price

Get Price Send Email

Send Email