In the realm of chemical synthesis, high pressure chemical reactors are rapidly gaining prominence. These reactors, operating under elevated pressures, offer a unique environment for a plethora of chemical reactions. Unlike conventional reactors, high pressure reactor manufacturers facilitate reactions at an accelerated rate, opening new pathways for synthesis that were previously unachievable.

The principle behind these reactors is simple yet profound. By increasing the pressure within the reactor, the solubility of gases in liquids significantly increases. This enhancement is crucial for reactions involving gaseous reactants. Moreover, high pressure often leads to an increase in reaction rates, thereby reducing the time required for the chemical process.

The Design and Construction of High Pressure Chemical Reactors

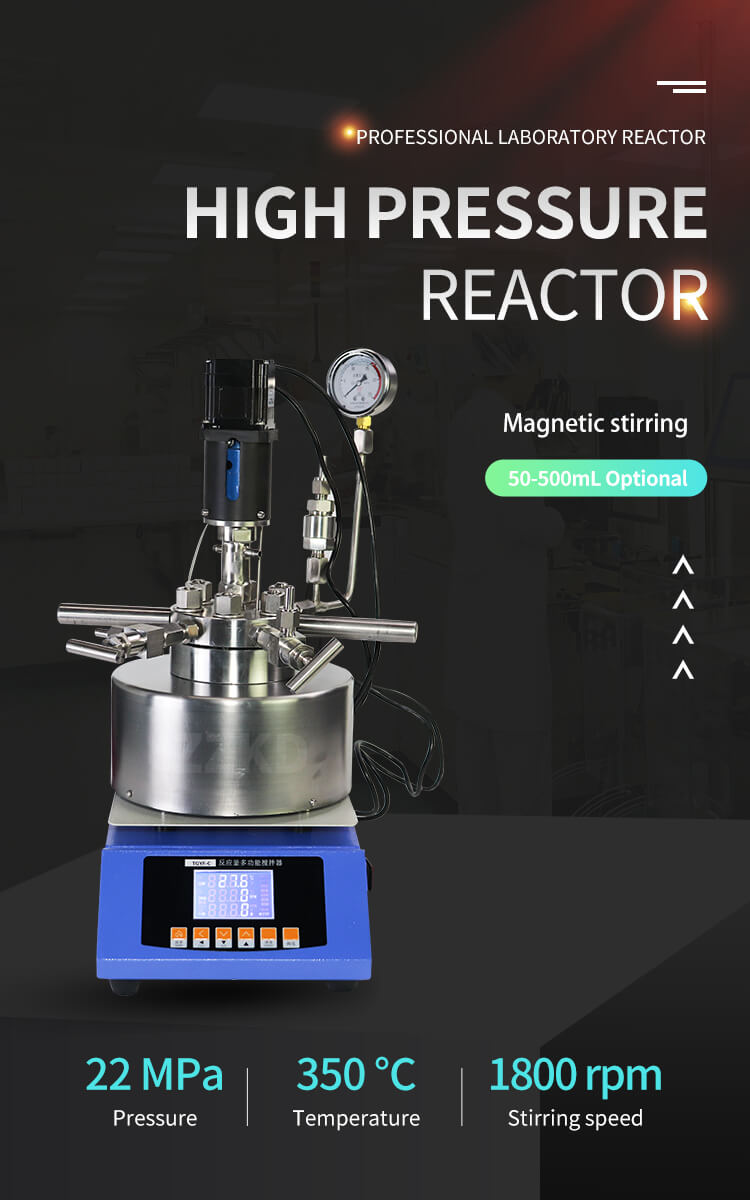

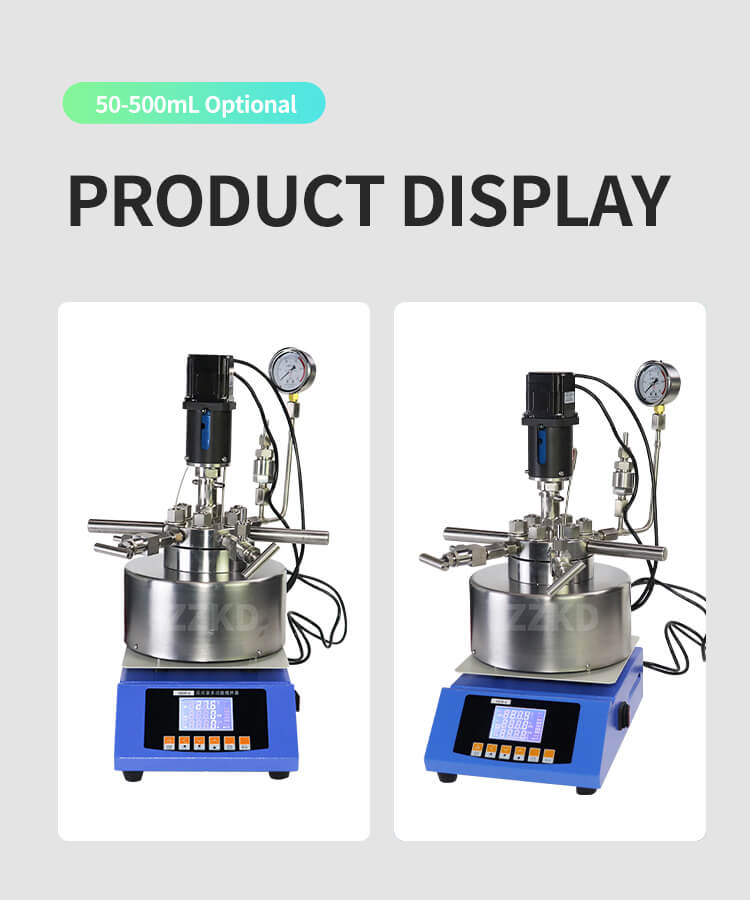

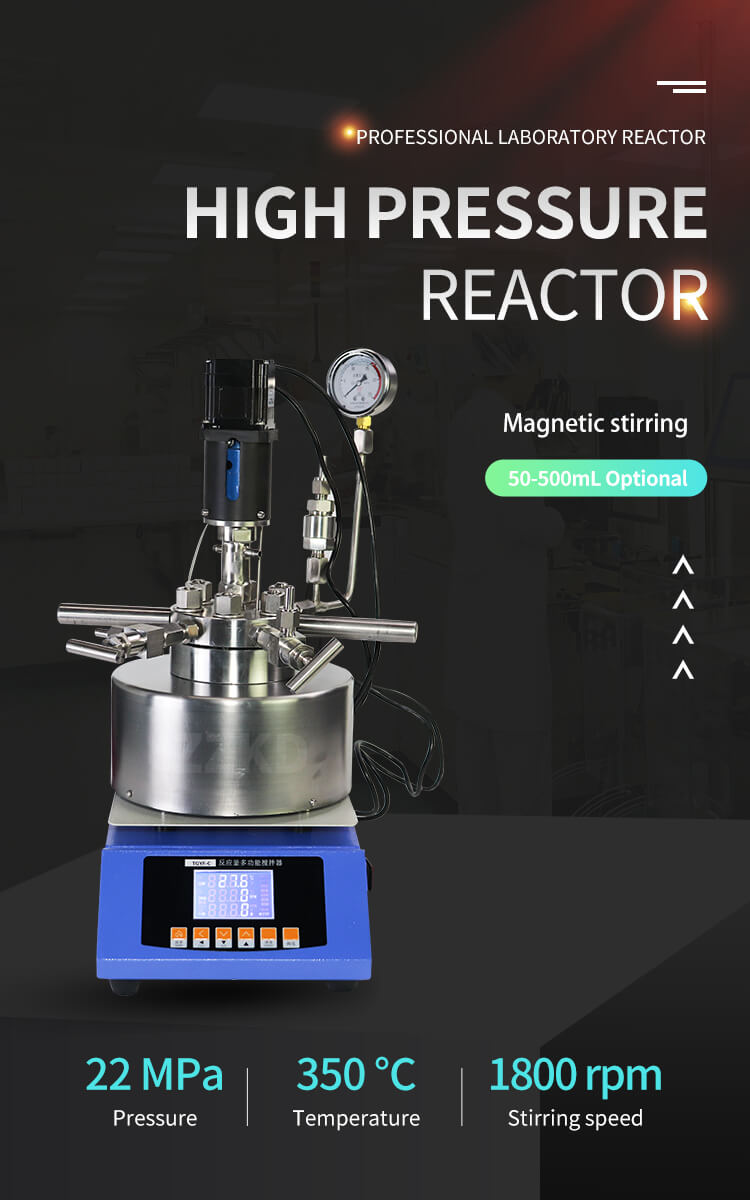

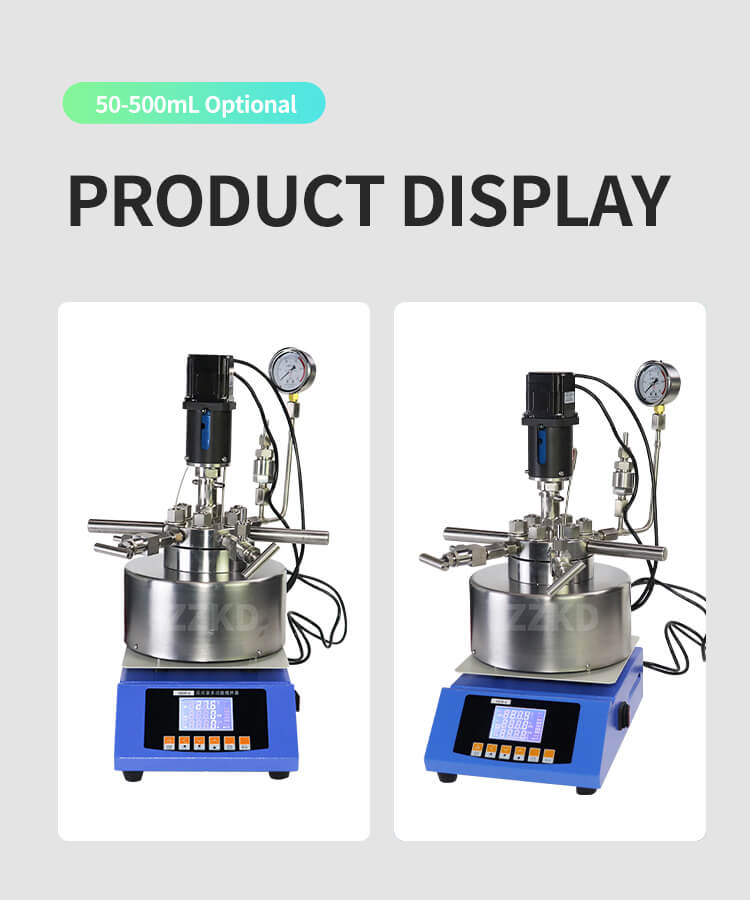

High pressure chemical reactors are marvels of modern engineering, designed to withstand extreme conditions. Their construction often involves robust materials like stainless steel and alloys, capable of enduring high pressures and temperatures. The design is meticulously planned to ensure safety, efficiency, and durability.

The core of these reactors is the vessel, which is engineered to handle pressures ranging from a few bar to several hundred bar. The vessel is often surrounded by a safety enclosure, which serves as a protective barrier. Inside, the reactor is equipped with sensors and control systems to precisely monitor and regulate temperature and pressure, ensuring optimal conditions for the chemical reactions.

The Role of Safety in High Pressure Reactor Operations

Safety is paramount when dealing with high pressure chemical reactors. The elevated pressures and temperatures inside the reactor pose significant risks, making safety features an indispensable part of the reactor design. Manufacturers incorporate multiple safety layers, including pressure relief systems, robust containment structures, and emergency shutdown mechanisms.

Operators of high pressure chemica reactors are extensively trained in safety protocols. Regular maintenance and inspection are critical to ensure the integrity of the reactor. Safety audits and compliance with industry standards are a routine part of the operational process, ensuring that these reactors are not only efficient but also safe for use.

Advanced Control Systems in High Pressure Chemical Reactors

The technological advancements in control systems have significantly enhanced the performance of high pressure chemical reactors. Modern reactors are equipped with sophisticated control systems that allow for precise manipulation of internal conditions. These systems monitor various parameters like pressure, temperature, and reaction rate, adjusting them in real-time to optimize the reaction process.

Advanced control systems are integral to achieving consistent results in chemical synthesis. They enable the automation of the process, reducing the need for manual intervention and minimizing the potential for human error. This automation not only enhances efficiency but also contributes to safety by maintaining the reactor within safe operational limits.

The Environmental Impact of High Pressure Chemical Reactors

High pressure chemical reactors have a notable impact on the environment, primarily in terms of reducing waste and energy consumption. The enhanced efficiency of these reactors means that chemical processes can be completed faster and with higher yields, reducing the amount of waste generated. This efficiency translates into lower energy consumption, as reactions that once took hours can now be completed in a fraction of the time.

Furthermore, the ability to carry out reactions under controlled conditions allows for the use of greener, less hazardous reagents. This aspect significantly reduces the environmental footprint of chemical manufacturing, aligning with global efforts towards sustainable industrial practices.

Future Trends and Innovations in High Pressure Reactor Technology

The future of high pressure chemical reactors is marked by continuous innovation and advancement. Researchers are exploring new materials and designs that can withstand even higher pressures and temperatures, further expanding the boundaries of chemical synthesis. There is a growing focus on miniaturization and modular design, aiming to make high pressure chemica reactors more accessible and versatile.

Emerging technologies, such as machine learning and artificial intelligence, are being integrated into reactor systems. These technologies offer the potential to predict optimal reaction conditions, thereby streamlining the process of developing new chemicals and pharmaceuticals.

Conclusion: The Pioneering Role of ZZKD in High Pressure Chemical Reactor Technology

ZZKD Machinery and Instrument Equipment Co., Ltd. stands at the forefront of these advancements in high pressure chemical reactor technology. With a legacy spanning over 13 years, ZZKD has established itself as a leader in the field, providing cutting-edge solutions tailored to the needs of the chemical and pharmaceutical industries. Their commitment to quality, innovation, and customer satisfaction has earned them a global reputation as a trusted manufacturer.

For those seeking to explore the possibilities offered by high pressure chemical reactors, ZZKD is the go-to partner. They offer a range of reactors, designed with the latest technology and built to the highest standards. Their expert team provides comprehensive support, from selecting the right reactor to post-sale services.

To learn more about how ZZKD's high pressure chemical reactors can revolutionize your chemical synthesis processes, visit their website. Discover the technology that's shaping the future of chemical manufacturing and join the ranks of satisfied customers worldwide who trust ZZKD for their high pressure reactor needs.

Products

Products