Struggling with preserving samples or creating unique products? Benchtop freeze dryers offer a compact solution. Get ready to explore this amazing technology.

A benchtop freeze dryer, or lyophilizer, removes water from frozen samples via sublimation under vacuum. This preserves material structure, extends shelf life, and is ideal for labs and small-scale production. It's great for food, pharmaceuticals, and research.

As a manufacturer with over 16 years in this field, I've seen how these machines transform research and production. It's truly rewarding to see our equipment help scientists and businesses. Let me share some insights I've gathered over the years, from basic operations to choosing the right model for your specific needs.

What Exactly Is a Benchtop Freeze Dryer and How Does It Work?

Curious about the magic behind freeze drying? It seems complex, but the science is fascinating. Let's break down this essential lab equipment simply.

Benchtop freeze dryers first freeze your material. Then, a strong vacuum is applied, and slight heat helps the frozen water turn directly into vapor (sublimation), bypassing the liquid stage. This preserves the item's structure beautifully.

The entire process, formally known as lyophilization, is a delicate dance of temperature and pressure. We are essentially tricking water into skipping its liquid phase. I remember when we first started designing these; getting the vacuum seal just right on the chamber door was a big challenge, but it's absolutely crucial for efficient sublimation. If the vacuum isn't strong enough, the process takes much longer, or might not even work correctly.

The Science: Sublimation Explained

Water has a special point on its phase diagram called the "triple point," where solid, liquid, and gas can coexist. By lowering the pressure well below this triple point, and then gently warming the frozen sample, we encourage the ice crystals to convert directly into water vapor. This vapor is then drawn away and collected on a very cold surface called the condenser. It's like how snow can slowly disappear from your yard even when the air temperature stays below freezing – that's sublimation happening naturally, just much slower! We simply create the perfect, accelerated conditions inside the freeze dryer. You can learn more about what is lyophilization and why is it used to understand the fundamentals better.

Key Components and Their Roles

Understanding the main parts helps you appreciate how it all works together. I've spent countless hours with our engineering team optimizing each of these.

|

Component |

Role |

|

Chamber |

This is where you place your samples. It needs to be well-sealed to maintain the vacuum. |

|

Condenser |

A very cold surface (often coils) inside the unit that traps the water vapor removed from your samples, turning it back into ice. |

|

Vacuum Pump |

This is the heart of the low-pressure system. It removes air and water vapor from the chamber and condenser. |

|

Refrigeration System |

Cools both the shelves (to freeze the product initially, if applicable) and the condenser to very low temperatures. |

|

Control System |

Manages the temperature, pressure, and timing of the different stages of the freeze-drying cycle. This can range from simple manual controls to sophisticated programmable logic controllers (PLCs). |

This gentle drying method is why it's so popular for delicate materials like proteins or microbes, as it avoids the damage that heat-drying can cause.

What Are the Key Applications for a Benchtop Freeze Dryer?

Wondering if a benchtop freeze dryer fits your needs? Its uses are incredibly diverse. You might be surprised by its versatility in various industries.

These machines are vital in pharmaceuticals for preserving drugs and vaccines, in food processing for creating long-shelf-life products like astronaut ice cream or freeze dried candy, and in research labs for sample preparation.

Over the years, I've had the pleasure of seeing our benchtop freeze dryers used in so many interesting ways. It's not just about standard lab work; people get really creative!

Pharmaceutical and Biotech Uses

This is a huge area. Stability is absolutely key for many biological products. Many vaccines, antibiotics, proteins, and microbial cultures are not stable in liquid form for extended periods or at room temperature. Freeze drying (lyophilization) converts them into a dry powder that is much more stable, easier to store, and can be reconstituted with sterile water just before use. I recall a client who was developing a new, very sensitive antibody treatment; our benchtop unit was perfect for their early-stage research and development, allowing them to test different formulations and drying protocols on a small scale before scaling up. This careful preservation maintains the product's effectiveness.

Food Industry Innovations

This is where things get fun for many people! Freeze-dried fruits, vegetables, coffee, complete meals, and even ice cream are common. The process retains much of the food's original shape, color, flavor, and nutritional value, which is a big advantage over other drying methods. Think about lightweight camping food or emergency food supplies – freeze drying makes them possible. We've even had customers using our mini freeze dryer machine for developing artisanal coffee powders and unique snack items. The texture change in things like candy is also a popular outcome.

Research and Academia

In university and institutional research labs, benchtop freeze dryers are often workhorses. They are used for concentrating solutions, preserving tissues or cell cultures for later analysis, preparing samples for electron microscopy, and even in fields like archaeology for preserving delicate waterlogged artifacts. I once visited a botany lab where they were using one of our units to preserve rare plant specimens for long-term study without damaging their delicate structures. It's amazing how this technology supports scientific discovery across so many disciplines.

Niche and Creative Applications

Beyond the major industries, there are some fascinating niche uses. For example, taxidermists sometimes use freeze drying to preserve small animals. Florists can use it to perfectly preserve wedding bouquets or other special occasion flowers, maintaining their shape and color beautifully. The ability to remove water without significantly shrinking or altering the material's structure is the key benefit here. It's always exciting to hear about these unique applications from our customers.

What Should I Look For When Choosing a Benchtop Freeze Dryer?

Ready to buy, but feeling overwhelmed by options? Choosing the right freeze dryer is important. Let's simplify the key factors for your decision.

Consider condenser temperature (colder is better for low freezing point samples), capacity (shelf area and ice capacity), vacuum pump quality, and control features. Also, think about material compatibility and our always-available after-sales support.

Choosing a freeze dryer is a significant investment, so it's worth taking the time to match the machine to your needs. I always tell my clients, "Let's talk about what you want to dry, and how much of it." That's the starting point.

Condenser Temperature and Capacity

The condenser temperature is critical. A standard condenser around -50°C to -55°C is generally fine for samples that are mostly water. However, if your samples contain organic solvents or have very low eutectic points (the lowest temperature at which they can melt), you'll need a colder condenser, perhaps -80°C or even lower, to trap those vapors effectively. Ice capacity refers to how much ice the condenser can hold before it needs to be defrosted. This will determine how much water you can remove in a single run or how long you can run the machine continuously. Shelf area or volume capacity dictates how much physical product you can load.

Shelf Configuration and Material

How will you load your product? Some units have shelves for drying products in trays or bulk. Others might have attachments for connecting flasks (manifold drying). If you're working with pharmaceuticals in vials, you might need a unit with a stoppering mechanism that allows you to seal the vials under vacuum or inert gas at the end of the cycle. Heated shelves can significantly speed up the secondary drying phase (removing bound water) by providing controlled energy input. Most reputable machines use stainless steel for shelves and the chamber for durability and ease of cleaning.

Vacuum System

A good, reliable vacuum pump is essential. Most benchtop freeze dryers use two-stage rotary vane pumps, which require oil. Some oil-free (dry scroll) pumps are available, which reduce maintenance but can be more expensive. Ensure the pump is correctly sized for the freeze dryer. We always recommend choosing a pump that can achieve a deeper vacuum than strictly needed, as this provides a margin for performance and longevity.

Controls and Data Logging

Modern freeze dryers can offer a range of control systems. Simpler units might have manual controls for temperature and vacuum. More advanced models feature programmable cycles, allowing you to set specific temperature ramps, hold times, and vacuum levels for different stages of the process. Data logging capabilities are crucial for research, process development, and quality control, allowing you to record and export cycle parameters. While considering features, it's also practical to investigate the lyophilizer price, as more advanced controls often influence the overall cost.

Footprint and Installation Requirements

Lab space is almost always at a premium! Check the dimensions of the unit, including any necessary clearance for ventilation or access to the vacuum pump. Also, verify the electrical requirements (voltage, phase, amperage) to ensure your lab can support it. I always advise clients to measure their available space twice before ordering!

How Do I Maintain My Benchtop Freeze Dryer for Optimal Performance?

Got your freeze dryer? Proper care ensures it runs smoothly for years. Neglecting maintenance can lead to costly issues and downtime for your projects.

Regularly defrost and clean the condenser. Check and change vacuum pump oil (if applicable). Inspect door seals and clean the chamber. Follow the manufacturer's specific maintenance schedule for the best, long-lasting results.

A well-maintained freeze dryer is a happy freeze dryer, and a happy freeze dryer means reliable results for you. I've seen units last for many, many years with just a bit of consistent care. It's like any precision instrument; it thrives on attention to detail.

Daily or Per-Run Checks

Before each run, it's good practice to do a quick visual inspection. Check the door seal for any debris or damage. Ensure the condenser is free of excessive ice from a previous run (if not defrosted). When the unit is running, listen for any unusual noises from the vacuum pump or refrigeration system. Keeping an eye on the process parameters (temperature and vacuum readings) during a run can also help you spot if something is starting to go wrong. Many of our customers keep a logbook for each machine.

Regular Cleaning and Defrosting

After each cycle, or as needed depending on usage, the condenser must be defrosted. Allow all the ice to melt and drain it properly. Once defrosted, it's good to wipe the condenser chamber dry. The product chamber should also be cleaned regularly with appropriate, non-corrosive cleaning agents recommended by the manufacturer. This prevents cross-contamination between batches and ensures efficient ice collection on the condenser. We learned early on in our manufacturing journey that good drainage and easy access for cleaning are key design features.

Vacuum Pump Care – The Unsung Hero

The vacuum pump is arguably the hardest working part of the system.

-

Oil Changes: For oil-sealed rotary vane pumps, regular oil changes are absolutely vital. The oil lubricates, seals, and cools the pump. Over time, it gets contaminated with water vapor and other condensables, which reduces its ability to achieve a deep vacuum. Follow the manufacturer's recommended oil change interval, or change it more frequently if you are processing "dirty" samples.

-

Gas Ballast: Most oil-sealed pumps have a gas ballast valve. Using this for a short period before shutting down the pump helps to purge water vapor and other volatile contaminants from the pump oil, extending its life.

-

Oil-free pumps: These require less day-to-day maintenance (no oil changes) but still need periodic checks as per the manufacturer's guidelines, such as inspecting or replacing tip seals in scroll pumps.

Annual Checks and Professional Service

Consider having an annual check-up by a qualified technician, especially for units used in critical applications or regulated environments. They can perform more thorough inspections, conduct vacuum leak tests, check the refrigeration system's performance, and calibrate sensors if needed. As a manufacturer, we offer comprehensive service plans because we know that proactive maintenance is the best way to maximize the lifespan and reliability of your equipment. It's an investment in uninterrupted operation.

Conclusion

In summary, benchtop freeze dryers are powerful, versatile tools for many labs. Proper selection, understanding its operation, and consistent care will unlock their full potential for your important work.

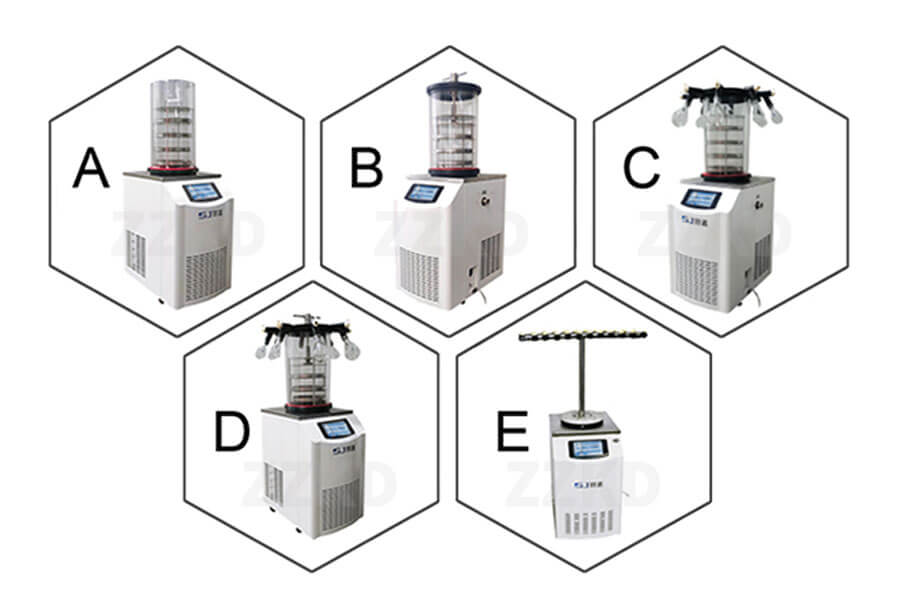

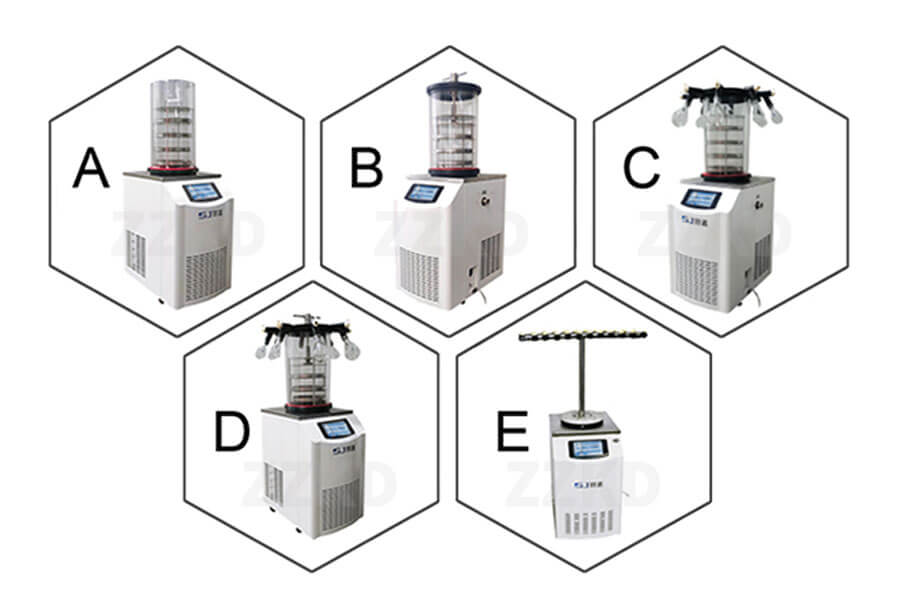

Products

Products