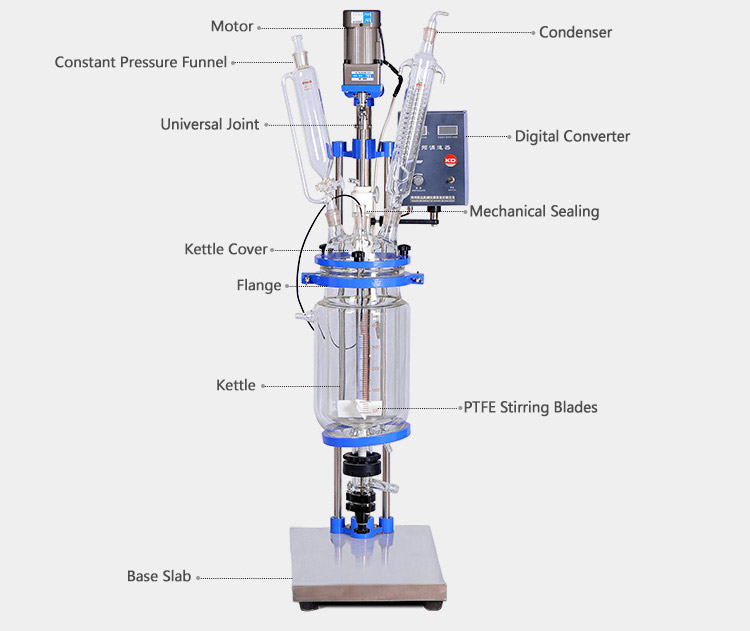

Description

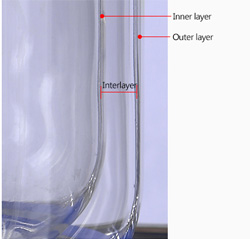

Double-glazed designed glass reactor, the liner is for reaction solvent, and the jacket for heating or cooling resource(cool liquid,hot water or hot oil), to achieve circulating heating or cooling experiment. And its ancillary equipment-High and low temperature machine which can satisfy functional high & low temp reaction experiments.

Ancillary Equipment

Circulating water vacuum pump:To provide a vacuum source

Cool chiller:low temperature reaction and Re-flux, condensation

Circulating water/oil bath:Thermal power

High and low temperature machine: high and low temperature experiment reaction

Features

1.GG17 high-borosilicate glass with nice physical-chemical properties; experiment temperature -100 to 400 degree C; Resistant to strong acidic properties of materials; only touching with glass parts & PTFE, no cross-contamination. Double cylinder; kettle cover is separated from kettle body. It is convenient to disassemble, clean and install.

2. Stirring adopts to mechanical sealing, it keeps higher vacuum degree among the same products in the market. It also keeps high vacuum degree when stirring. Glass(PTFE)discharge valve, non-dead angle mixing, fast emptying, no residue.

Gear Motor

International copper wire; High efficiency, long operation, good stability, high torque, no brush,no spark; Standard gears, no gap and abrasion resistance; CE Approved

Spiral Condenser

The inner tube is spiral which increases the length of the tube and makes cooling area larger. So the condensation would be more efficient.

Constant Pressure Funnel

Temp Range -100℃~400℃; High acid and alkali resistant, high temperature resistant, high strengh and hardness; Feed rapidly, no residual and easy clean.

Electric Heating Mantle

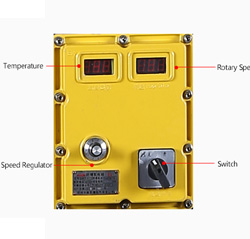

Built-in chip, precise temperature control(Accuracy: ±0.1℃), easy operation, reliable performance, display directly and easy observation.

Package:

1. We package these glass equipment in good and non fumigation standard plywood case.

2. It will be decided according to your quantity. Normally we will choose International Express, Air and sea.

3. Normally we accept TT, Paypal, Western Union, Alibaba Escrow, and L/C. The exactly term will be discussed during the deal.

4. In 5 working days after payment confirmed, customized products need 10~15 working days.

Products

Products

Get Price

Get Price Send Email

Send Email