Description

10L Jacketed glass raector advantages:

Frequency management motor

Stable operation

High vacuum degree

Constant velocity stirring

Precise temperature control

Efficient distillation

10L Jacketed glass reactor details:

Constant strain funnel

Feed quickly,no residual,acid and alkali resistance,temp range:-100℃-400℃.

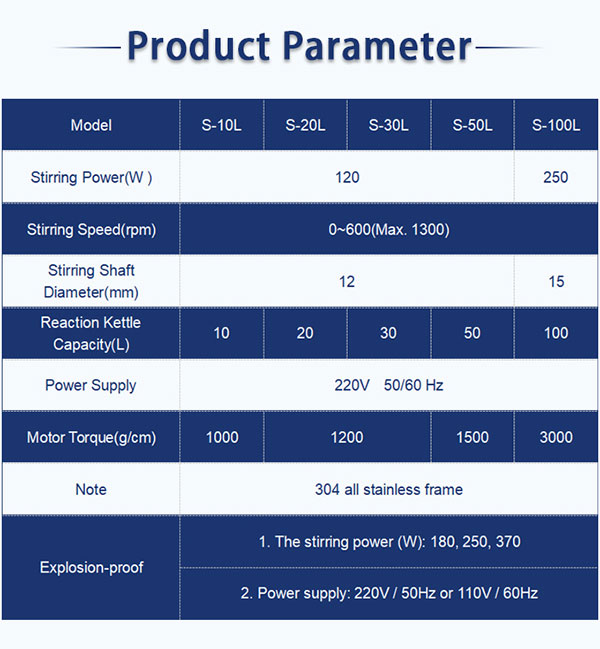

Gear motor

Smooth working,high torque,automated booster,no spark,explosion proof is optionally available.

Kettle cowl

It is handy to scrub,disassemble,and install PT100 temperature probe.

Double layer glass kettle physique

High quality borosilicate 3.3 glassware.

FAQ

You can also use each reactors as materials vessels, or one reactor could be utilized for giant batch winterization and separation whereas the other is used for extraction. Here we offer quite so much of glass reactors with volumes from 500mL to 200L. They could be made into system items with multi-function circulating water vacuum pump, diaphragm vacuum pump, low temperature circulating pump, circulating cooler, constant temperature circulator and cooling and heating circulating machine.

After all, having the proper jacket is vital to sustaining one of the best temperature for the 10L jacketed glass reactor. Browse our alternative of laboratory glass reactors today to discover a system or particular person part that works for you. A single layer glass reactor has a quantity of capabilities in daily life. Based on the design, it could be utilized in laboratory exams, chemistry, and biology and even within the pharmaceutical enterprise. In chemical engineering, a jacketed vessel is a container that's designed for controlling temperature of its contents, by using a cooling or heating "jacket" across the vessel by way of which a cooling or heating fluid is circulated.

The glass reactor is an ideal examine and production gear for the preparation of contemporary synthetic chemical substances, biopharmaceuticals and new supplies. The common understanding of jacketed glass reactors vessel is that there are bodily or chemical response vessels. Through the structural design and parameter configuration of the vessels, the heating, evaporation, cooling and low-speed mixing capabilities required by the strategy are realized.

The 10L jacketed glass reactor is injected into the thermostat by way of the double-layer reactor. The sizzling solution or the cooling liquid is heated or cooled at a continuing temperature within the reactor, and stirring could be offered. Thus, the medium within the interlayer of the glass reactor is subjected to a cyclic response by stirring to achieve heating or cooling. It is broadly used as an ideal equipment in modern biochemical new materials synthesis experiments.

The glass reactor mainly makes use of the traits of its double-layer glass. We can place the response materials within the center interlayer , and stir the reaction beneath normal stress or adverse pressure. Thus, the medium in the interlayer of the glass reactor is stirred to carry out a heating response or cooling. CSTR reactors are batch reactors with an open methods and have impeller geared up with it to offer agitation for correct mixing or reactor content material. These reactors allow adding continuous uncooked materials into the reactor and steady removal of product.

Products

Products

Get Price

Get Price Send Email

Send Email