Struggling with precise temperature control for your chemical reactions? Need better visibility and versatility in your lab experiments? This might be your answer. As a manufacturer, we know these pains.

A lab reactor jacketed glass vessel is specialized laboratory equipment. It allows for controlled chemical reactions, mixing, and observation. Its jacket enables precise temperature regulation by circulating fluids, making it essential for many research and development processes.

As a company dedicated to lab instruments for over 16 years, I've seen how the right tools can transform research. A jacketed glass reactor isn't just another piece of glassware; it's a core component for innovation. Let me share why it might be the key to unlocking new possibilities in your lab work. We always aim to provide solutions that make your complex tasks easier.

How Does a Jacketed Glass Reactor Actually Work?

Confused about how these reactors manage temperature so well? Wondering what makes the "jacket" so special for your experiments? Let's clarify its function simply.

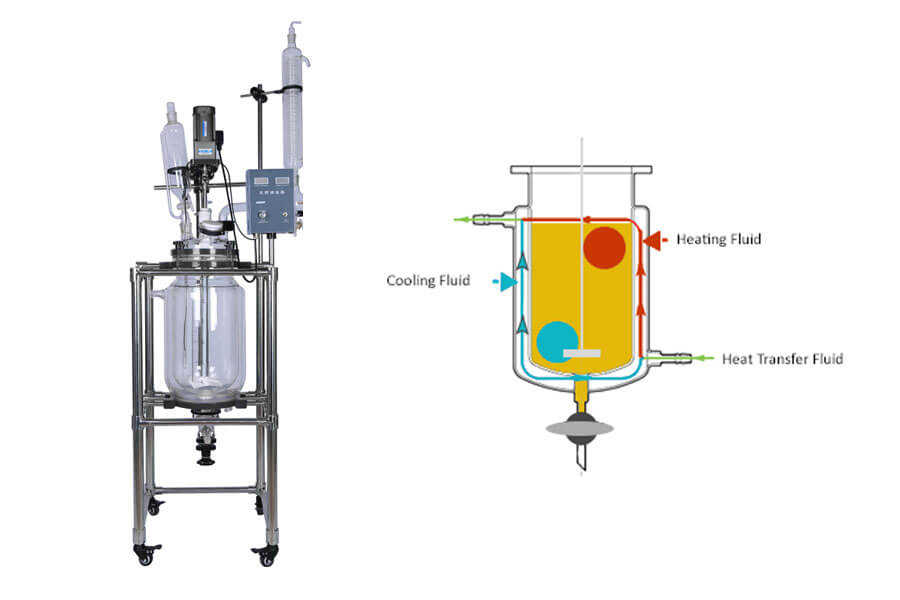

The reactor has an inner glass vessel for your materials and an outer glass jacket. A thermal fluid circulates within this jacket. This fluid can be heated or cooled, transferring that temperature to the inner vessel, ensuring precise reaction conditions.

Understanding the mechanics of a jacketed glass reactor is key to using it effectively. Imagine two glass containers, one neatly fitting inside the other, with a space between them. The inner container is where your chemical reaction takes place. The space between the inner and outer container forms the "jacket." This jacket is connected to a circulating bath, which pumps a thermal fluid – like water, silicone oil, or a glycol mixture – through it. If you need to heat your reaction, the circulator heats the fluid. If you need to cool it, the circulator cools the fluid. This constant flow of temperature-controlled fluid around the inner vessel ensures that your reaction mixture is kept at a very stable and uniform temperature. This is so important for reactions that are sensitive to temperature changes. We also equip these reactors with an overhead stirrer to ensure the contents are mixed well, which further helps with temperature uniformity and reaction efficiency. Many times, I've helped clients troubleshoot reactions, and often, precise temperature control provided by the jacket was the solution to inconsistent results. The lid of the reactor usually has several ports for adding reactants, inserting temperature probes, or connecting a condenser for reflux or distillation.

Key Components and Their Functions:

|

Component |

Function |

|

Inner Vessel |

Holds the reaction mixture. Made of borosilicate glass for chemical resistance. |

|

Outer Jacket |

Surrounds the inner vessel; thermal fluid circulates here for temperature control. |

|

Lid |

Seals the reactor. Contains multiple ports for stirrer, probes, addition funnels, condensers, etc. |

|

Overhead Stirrer |

Mixes the reactants, ensuring homogeneity and efficient heat transfer. Various stirrer designs are available. |

|

Thermal Fluid Inlet/Outlet |

Ports on the jacket for connecting to a temperature control unit (circulating bath). |

|

Discharge Valve |

Located at the bottom of the inner vessel for easy draining of products. |

← Swipe Left and Right to View the Table→

Many of our systems can also be operated under vacuum, which is useful for lowering boiling points during distillation or removing solvents. We ensure our designs allow for this flexibility because modern research often demands it.

What Are the Key Advantages of Using a Jacketed Glass Reactor in a Lab?

Are your current setups limiting visibility or temperature accuracy? Seeking equipment that offers flexibility and durability for diverse chemical processes? We see these needs often.

Key advantages include excellent visibility of reactions due to the glass construction, precise temperature control via the jacket, chemical resistance of borosilicate glass, and versatility for various reactions like synthesis, distillation, and crystallization.

When I talk to researchers, certain benefits of jacketed glass reactors always come up. First is the enhanced visibility. Because the main vessel is made of clear borosilicate glass, you can see everything that’s happening inside – color changes, phase separations, crystal formation. This is invaluable for understanding and monitoring your reaction. I remember a university team struggling with an unclear reaction endpoint; switching to one of our glass reactors gave them the visual cues they needed.

Second, precise temperature control is a game-changer. The jacket system allows for very accurate heating and cooling. Whether your reaction is exothermic (releases heat) or endothermic (absorbs heat), the circulator and jacket work together to maintain the set temperature. This stability is crucial for reproducibility and for reactions where even small temperature deviations can affect yield or purity. We often pair our reactors with high-quality temperature control units to maximize this benefit.

Then there's chemical resistance and purity. We use high-quality borosilicate 3.3 glass for all wetted parts. This type of glass is very inert and resistant to almost all chemicals, except for strong hydrofluoric acid, strong alkalis, and hot concentrated phosphoric acid. This means your reactions won't be contaminated by the reactor material itself. For more information about the uses, you might find our article on what a glass reactor is used for quite helpful. The versatility also extends to integration with other equipment, like rotary evaporators for solvent removal, which we also manufacture.

Lastly, these reactors offer versatility in application. They can be used for a huge range of chemical processes: synthesis, distillation, crystallization, extraction, and more. We offer various sizes, from small lab glass reactors (1L, 5L) up to larger pilot-scale units like a 100 liter glass reactor, catering to diverse needs. This adaptability makes them a long-term investment for many labs.

Which Industries Benefit Most from Jacketed Glass Reactors?

Wondering if this equipment fits your specific field? Curious about its applications beyond general chemistry? Let's explore its widespread industrial and research relevance.

Chemical, pharmaceutical, and biotech companies heavily rely on these reactors for R&D and pilot production. Academic institutions, food & beverage, and materials science labs also find them indispensable for various processes.

Over my 16 years in this business, I've seen our jacketed glass reactors become vital tools across many sectors. The pharmaceutical industry is a major user. They use our reactors for active pharmaceutical ingredient (API) synthesis, process development, purification, and crystallization studies. The ability to control temperature precisely and observe the reaction is critical when developing new drugs.

Similarly, the broader chemical industry uses them for synthesizing new compounds, optimizing reaction conditions, and small-scale production. Whether it's specialty chemicals or polymers, the versatility is key. In biotechnology and life sciences, while specialized bioreactors are common for cell culture, jacketed glass reactors are still used for extracting biomolecules, buffer preparation, and other temperature-sensitive processes.

Academic universities and research institutions are perhaps the most diverse users. From basic chemistry research to materials science and chemical engineering labs, our reactors help students learn and researchers innovate. They are perfect for demonstrating reaction principles. The food and beverage industry uses them for developing new flavors, extracting essential oils (a process where temperature control is crucial, as detailed in some essential oil extraction guides), and quality control. Even emerging industries like cannabis and hemp processing utilize jacketed reactors for steps like winterization and decarboxylation, ensuring product purity and consistency. It's truly rewarding to see our equipment play a role in so many different fields of innovation.

Specific Use Cases:

-

Pharmaceuticals: API synthesis, scale-up studies, formulation.

-

Chemicals: New compound development, kinetic studies, catalyst screening.

-

Academia: Teaching labs, fundamental research projects.

-

Food & Beverage: Natural product extraction, flavor development.

-

Materials Science: Polymer synthesis, nanoparticle creation.

How Do I Choose the Right Jacketed Glass Reactor for My Needs?

Feeling overwhelmed by options? Unsure what specifications matter most for your specific application? Let's break down the selection process to make it easier.

Consider reaction volume, temperature range, pressure requirements, material compatibility, and necessary accessories like stirrers or condensers. Consulting with experienced manufacturers like us at ZZKD can simplify this decision significantly.

Choosing the right jacketed glass reactor is a critical step. I always advise my customers to think carefully about their specific needs. First, consider the Volume or Capacity. How much material will you be working with? We offer a range from small benchtop models, like 1L or 5L, ideal for research and development, up to larger pilot-scale units such as 50L or even 100L jacketed glass reactors for small-batch production or more extensive scale-up studies. It's wise to choose a size that accommodates your typical batch but also offers some flexibility for slightly larger volumes if needed.

Next, what is your required Temperature Range? Standard systems with oil baths can typically go from -80°C (with specialized chillers) up to 200°C or even 250°C. Some very high-temperature applications might need different setups. This will influence the choice of thermofluid and the heating/cooling circulator. Also, think about Pressure and Vacuum Needs. Our standard glass reactors are designed for atmospheric pressure or moderate vacuum. If you need to work at high pressures, you’ll need to look at specialized stainless steel reactors, which we also provide.

The Stirring Requirements are also important. What kind of materials will you be mixing? Are they viscous? This will determine the type of stirrer (e.g., anchor, propeller, turbine, PTFE-coated), the motor power, and the speed range needed. We can help select the optimal stirring assembly. Finally, consider the number and type of Ports and Accessories you'll require on the reactor lid for things like condensers, dropping funnels, temperature probes, pH meters, and vacuum connections. As experienced manufacturers, we often help customers configure a reactor that perfectly matches their application, ensuring they get the best value and performance. It's like choosing any lab instrument; understanding the scale, like for a lab scale glass reactor, helps define the path forward.

What Safety Precautions Should I Take When Operating a Jacketed Glass Reactor?

Concerned about safety in the lab? Want to ensure you're using your glass reactor correctly and minimizing risks? These tips are essential for safe operation.

Always wear appropriate PPE. Ensure glassware is free from cracks. Operate within pressure/temperature limits. Use a fume hood for hazardous substances. Securely clamp all components and check connections before starting.

Safety is our top priority, both in designing our equipment and advising our customers. When working with any laboratory equipment, especially glass reactors under temperature and mixing stress, following safety protocols is non-negotiable. I always stress a few key areas.

Before you even start: Thoroughly inspect all glassware components – the vessel, lid, condenser – for any chips, cracks, or star crazes. Even a small flaw can become a failure point under thermal stress or vacuum. Ensure all ground glass joints are clean, properly (but lightly) greased if necessary for vacuum, and securely clamped. Check that the stirrer shaft is aligned correctly and turns freely without scraping the vessel. Verify all tubing for the thermal fluid and any vacuum lines are in good condition and securely connected. It's like a pre-flight check; it prevents problems later.

During operation: Always wear your Personal Protective Equipment (PPE) – this means safety glasses or a face shield, a lab coat, and gloves appropriate for the chemicals you are handling. Heat and cool the reactor contents gradually. Rapid temperature changes can cause thermal shock and break the glass. Never exceed the manufacturer's specified maximum temperature and pressure limits for the reactor. If working with hazardous, volatile, or fuming substances, always operate the reactor inside a functioning fume hood. Keep an eye on the reaction. Visual monitoring is one of the benefits of a glass reactor, so use it!

After operation: Allow the entire system to cool down to a safe temperature before attempting to dismantle it or drain the contents. Be cautious when cleaning; use appropriate cleaning agents and soft brushes to avoid scratching the glass. Proper training for all users on standard operating procedures and emergency shutdown is also something we strongly recommend. We've built many safety features into our equipment, but user vigilance is irreplaceable.

Conclusion

Jacketed glass reactors are truly versatile and controllable tools, essential for modern labs. Understanding their function, benefits, and safe operation helps you achieve better research outcomes with reliable equipment like ours.

Products

Products