Description

Product Description

The Heater Chiller Circulator adopts a fully enclosed pipeline design and a high-efficiency plate heat exchanger, which reduces the demand for heat transfer fluid and improves the heat utilization rate of the system to achieve rapid temperature rise and fall. The heater Chiller Circulator is suitable for the control of heat-requiring and exothermic processes in the reaction process. It can accurately and linearly control the temperature of the material in the kettle. The program control mode can be selected, and the temperature difference between the heat transfer medium and the material can also be set. In addition, oil mist will not be generated at high temperatures, and moisture will not be absorbed at low temperatures. There is an expansion tank in the system, and the heat transfer medium will expand and contract during the cooling and heating process.

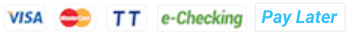

Main Component

Heater Chiller Circulator is mainly composed of a motor, controller, compressor, condenser, liquid storage tank, drying filter, pre-cooling heat exchanger, evaporator, etc.

Product Advantages And Features

1. It can realize continuous temperature rise and fall. It adopts compressor technology to operate under high temperature and high pressure. The compressor can be directly turned on for refrigeration from 350 degrees, which greatly improves the cooling rate and saves test time and energy.

2. The whole cycle is airtight, there is no oil mist volatilization at high temperature, the heat transfer oil is not easy to be oxidized and browned; it is not easy to absorb water vapor in the air at low temperature; prolongs the service life of heat transfer oil.

3. This equipment has various safety functions such as self-diagnosis function, freezer overload protection, high-pressure switch, overload relay, thermal protection, high-pressure protection device for circulation system during high-temperature heating, etc., to fully guarantee the safety of use;

4. Temperature adaptive control

In the process of controlling the process (such as the chemical reaction process), the adaptive control system continuously adjusts the PID parameters to give the process the best control temperature and response time. This process is through effective multi-directional measurement of temperature, temperature change, and rate of temperature change.

Applications

Heater Chiller Circulator is a temperature control system that can be used in many industries. It is usually used for refrigeration and heating temperature control in reaction kettles, reactors, extraction, distillation, etc., and is used in pharmaceutical, chemical, drying, biological, laboratory, and other industries. , then what are the process requirements in such an industry?

1. Heater Chiller Circulator supporting reactor application

The high and low-temperature cycle integrated machine and the reaction kettle are used for refrigeration and heating temperature control equipment, usually, the medium is used to control the refrigerant, and the temperature accuracy is an important factor of the equipment;

2. Heater Chiller Circulator supporting fermenter application

By controlling the temperature of the fermenter, it is beneficial to the speed of various enzyme reactions, changing the synthesis direction of metabolites, and affecting the regulation of microbial metabolism. In order to meet the required temperature requirements, a high and low-temperature cycle integrated machine is used to control the temperature of the fermentation tank in production, so as to provide a suitable temperature to achieve the required temperature and reaction effect.

3. Heater Chiller Circulator supporting distillation application

The high and low-temperature cycle integrated machine adopts a temperature control temperature gradient, and the high and low-temperature cycle integrated machine is used to control different temperatures to achieve the distillation temperature and ensure the condensation effect.

4. Application of Heater Chiller Circulator in the drying industry

During the operation of the drying equipment, various physical forms such as external temperature and humidity need to be brought to the expected state through the stirring operation of the drying equipment. At this time, a high and low-temperature integrated machine is required for heating operation. The high and low-temperature integrated machine can heat up to 350 degrees and can be heated through different media. The equipment runs stably, and it is smaller than the heat conduction furnace and easy to operate.

5. Application of Heater Chiller Circulator in the Adhesive Industry

In the adhesive industry, since such substances will generate a lot of heat after the polymerization reaction, it needs to be cooled down, otherwise, it will lead to various failures. Therefore, a high and low-temperature integrated machine is required to cool the reactor, and the traditional water cooling It will lead to the oxidation of the reactor, and there will be the risk of carbonization, which will bring a certain amount of pressure, which is not conducive to the improvement of production efficiency. The high and low-temperature all-in-one equipment operates stably, meets the required temperature requirements, and is more convenient for cooling.

FAQ

How many types of Heater Chiller circulators are there?

Heater Chiller Circulator is divided into oil-cooled high and low temperature integrated machines and water-cooled high and low temperature integrated machine according to the temperature and medium. Different temperatures require different media. Generally speaking, water at room temperature can be selected as the medium, heat transfer oil as the medium at high temperature, and refrigerant as the medium at low temperature.

The different cooling methods, it is divided into air cooling and water cooling. Thermal all-in-one.

How much does Heater Chiller Circulator cost?

Quality

The quality of a product is the main factor that determines its price. Because under normal circumstances, the manpower, technology, and materials that need to be spent on high-quality products also need to be corresponding. Only good materials and technology can produce high-quality products. Then, the product price will correspond to it.

Factory

The scale, technology, popularity, etc. of the manufacturer will also affect the price of the products produced. Large-scale, long-term, high-tech and well-known manufacturers produce products with high reliability, and their pricing will be higher than that of small-scale, newly opened, low-tech, and unknown manufacturers. Manufacturers will be higher. Even if the prices of these good manufacturers are higher, they are still within a reasonable range. Consumers will be willing to choose to buy on the basis of trust.

Products

Products

Get Price

Get Price Send Email

Send Email