Description

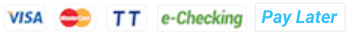

Introduction To Agitated Nutsche Filter Dryer

Agitated nutsche filter dryer is a kind of equipment used for drying wet materials. It combines the functions of stirring and filtering, and can efficiently evaporate and remove the water in wet materials to achieve the purpose of drying. The following is a detailed introduction about agitated nutsche filter dryer:

Working principle:

The agitated nutsche filter dryer stirs the wet material evenly through the movement of the agitator, and at the same time draws out the water through the filter during the stirring process. The rotation of the agitator increases the surface area of the wet material, which is conducive to the evaporation of water. The filter plays the role of separating the solid material and moisture, and the moisture is discharged through the filter, while the solid material remains in the dryer to complete the dryingprocess.

Advantages Of Agitated Nutsche Filter Dryer

1. Closed system: The three-in-one system of filtering, washing and drying is a fully closed system. Production and operation in a closed system can avoid air pollution by toxic substances and reduce the occurrence of poisoning accidents of operators.

2. Recycling: materials and solvents are basically recycled, avoiding waste caused by material omission and solvent volatilization, and has great economic benefits.

3. Multifunctional all-in-one machine operation: filtering, washing and drying are completed in the same equipment. The vessel walls are equipped with heating jackets to allow drying.

4. Continuous operation: Filtration and drying are carried out in a continuous system, no need to deal with wet filter cake. The dried product can be transferred mechanically to the weighing and packaging section.

5. Save manpower. Non-technical personnel can get started with simple training. Closing, automatic feeding, automatic discharging, no need for technicians to monitor.

6. Thorough cleaning: filtering, washing, and drying are three-in-one, with automatic spraying and stirring functions, the filter cake is fully cleaned, reducing sewage discharge, and reducing wastewater treatment costs.

7. Clean production: The multifunctional filter drying system is equipped with a dust collector to collect the dust produced after drying to meet the requirements of clean production.

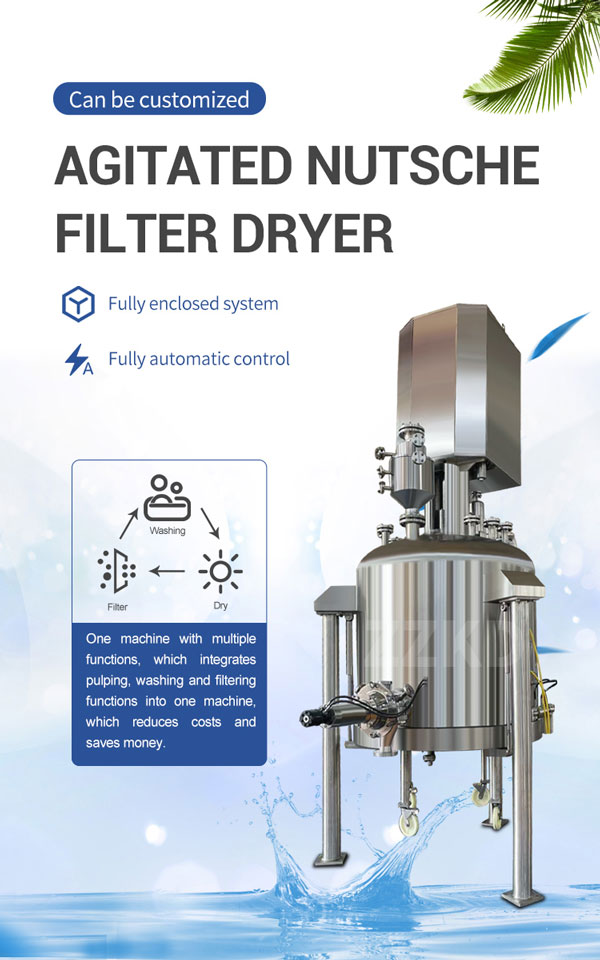

Fields Of Application Of Agitated Nutsche Filter Dryer:

Chemical industry:

The agitated nutsche filter dryer is used in the chemical industry to dry granular materials, granules, powders, etc. It can be applied to the manufacture of chemicals, the preparation of catalysts, the drying of synthetic resins, etc.

Pharmaceutical industry:

In the pharmaceutical industry, agitated nutsche filter dryer is often used in the drying of drugs and the production of preparations. It can be used to dry granular pharmaceutical raw materials, prepare solid preparations, etc.

Food industry:

Agitated nutsche filter dryer is widely used in food drying and processing in food industry. For example, it can be used to dry paste food, slurry food, suspension, etc.

Fine chemical industry:

Agitated nutsche filter dryer also has important application in fine chemical industry. It can be used in the drying of fine chemicals, the preparation of catalysts, the preparation of granular materials, etc.

Mining and Metallurgical Industry:

In the mining and metallurgical industry, agitated nutsche filter dryer is often used in the drying of ore, the preparation of metal powder, the treatment of solid waste, etc.

Environmental Protection Industry:

The agitated nutsche filter dryer is also used in the environmental protection industry, for example for the drying and treatment of sludge.

Maintenance:

Cleaning: Regularly clean the interior and exterior surfaces of the agitated nutsche filter dryer to remove accumulated dust and dirt. Use proper cleaning agents and tools, taking care not to damage the equipment.

Check the seals: Periodically check the seals on the mixer shaft seal and the dryer to make sure they are intact. If wear, aging or damage is found, replace the seals in time.

Check the transmission system: Regularly check the transmission system of the agitator, such as belts, gears and bearings. Make sure the transmission is functioning properly, if there is unusual vibration, noise or looseness, adjustments or replacement parts are required.

Check the heat source: Periodically check the dryer's heat source, such as a heater or heating rod. Make sure it is working properly and temperature control is accurate.

Check the filter: Check the filter of the dryer regularly to make sure it is unobstructed. If clogging or damage is found, clean or replace the filter in time.

Regular lubrication: According to the equipment instruction manual and recommendations, regularly lubricate the bearings and transmission parts of the agitator. Use an appropriate lubricant, following the lubricant's directions for use.

Regularly check the safety devices: Regularly check the safety devices of the dryer, such as overload protection devices, circuit breakers and emergency stop buttons, etc. Make sure it works properly.

FAQ

Q: The drying speed is too slow or the expected drying effect cannot be achieved.

A:

Check that the heat source is working properly to make sure the temperature is set correctly.

Check that the agitator is running properly, if it is not running smoothly or is not spinning enough, clean or replace the agitator.

Check to see if the filter is clogged and needs to be cleaned or replaced.

Check whether the material is too much or too little, and adjust the loading of the material.

Check the ventilation of the dryer to ensure good ventilation and exhaust.

Q: The mixer is too noisy or vibrates abnormally.

A:

Check whether the agitator is installed correctly and whether the fastening bolts are loose.

Check the agitator's bearings and seals for damage and replace damaged parts.

Check the agitator's transmission, such as a belt or gear system, to make sure it is functioning properly.

Q: It is difficult to discharge or the discharge port is blocked.

A:

Check whether the discharge device is working properly, such as transmissions, valves, etc., to ensure smooth operation.

Check whether there is blockage in the discharge port, and clean the discharge port to keep it unobstructed.

Check the humidity and viscosity of the material, it may be necessary to adjust the drying parameters to improve the fluidity of the material.

Products

Products

Get Price

Get Price Send Email

Send Email